Circuit breaker for motor protection

A circuit breaker and motor technology, which is applied in the field of motor protection circuit breakers, can solve the problems of poor gear coordination of the operating mechanism, limited short-circuit breaking capacity, and low service life, so as to improve the short-circuit breaking capacity, improve the meshing relationship and gears. Force situation, the effect of reducing the amount of wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following is attached Figures 1 to 9 The given examples further illustrate the specific implementation of the circuit breaker for motor protection of the present invention. The circuit breaker for motor protection of the present invention is not limited to the description of the following embodiments.

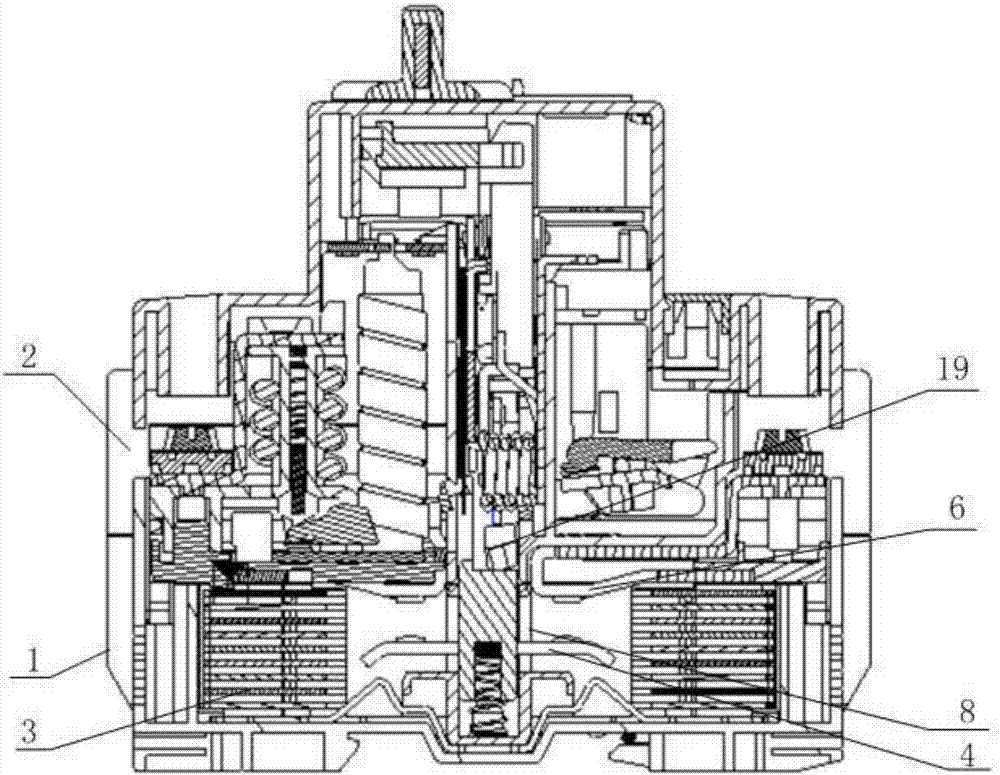

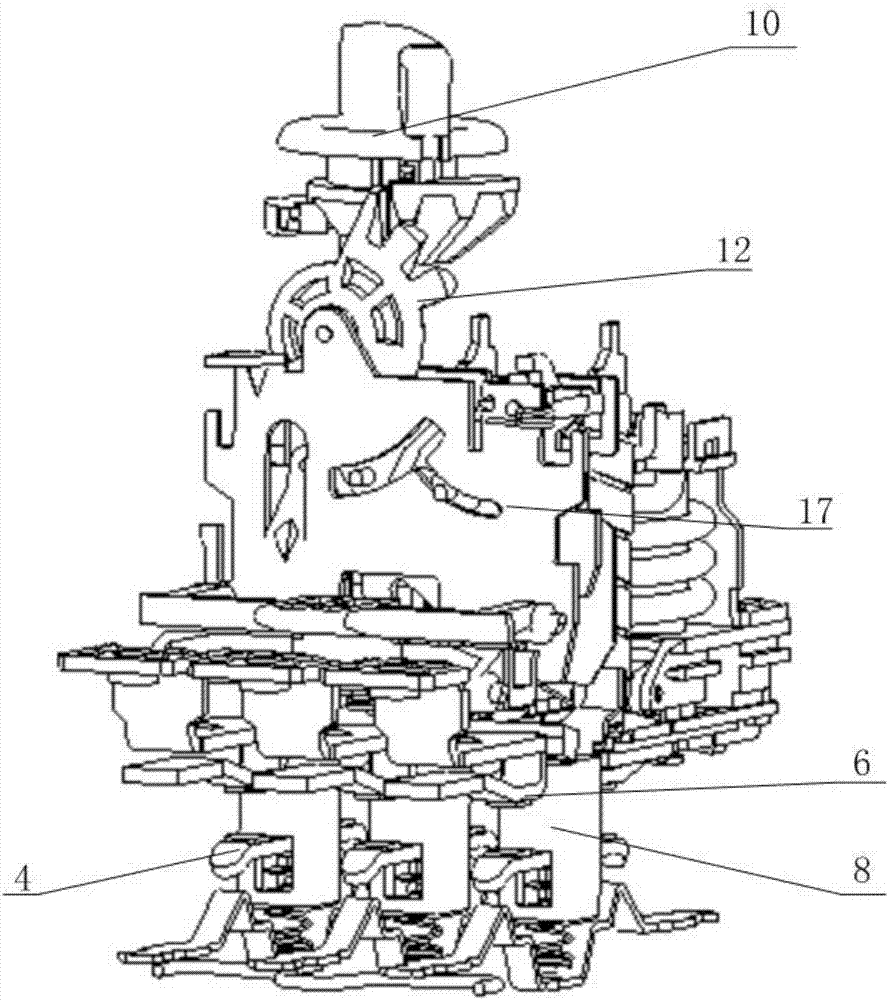

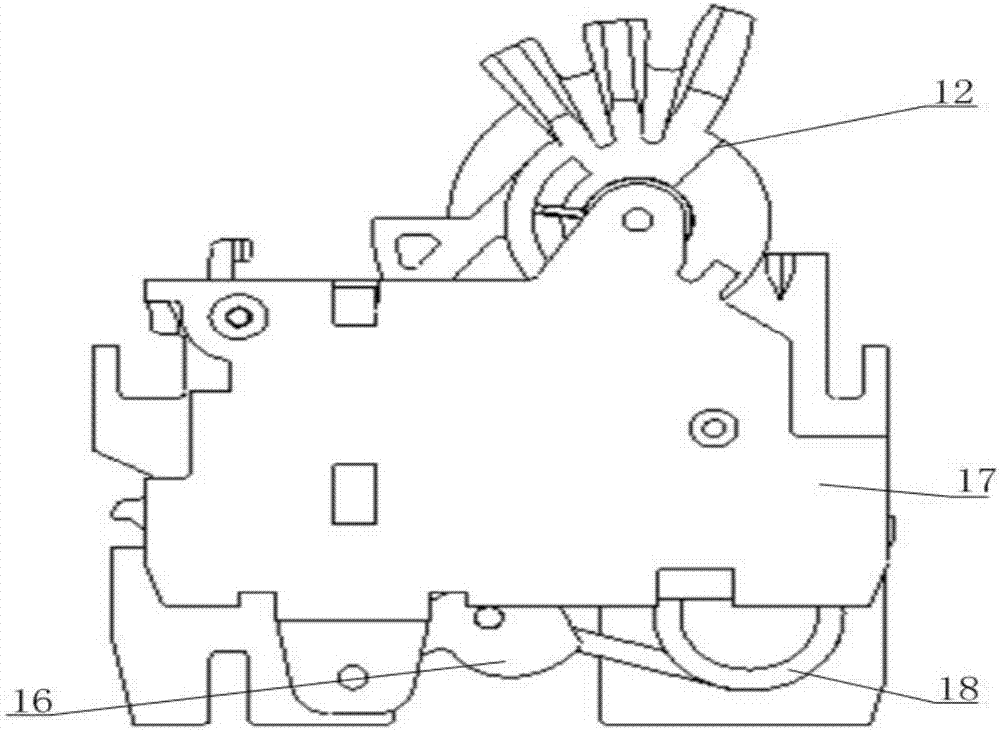

[0026] Such as figure 1 As shown, the circuit breaker for motor protection of the present invention includes a base 1 and a base 2 , and the base 2 is installed on the base 1 . The arc extinguishing grid group 3 is installed on the base 1, and the two sets of arc extinguishing grids of the arc extinguishing grid group 3 are respectively located on both sides of the base 1, and the middle part of the base 1 is installed with a contact support 8, and the contact support 8 is installed There is a moving contact group 4; a static contact group 6 is installed on the base 2, and the two sets of static contacts of the static contact group 6 are respectively arranged on b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com