Motor and motor protection method

An isolation protection, circuit technology, applied in emergency protection circuit devices, electrical components and other directions, can solve the problems of power tube breakdown, DC motor winding insulation damage, etc., to achieve the effect of rapid braking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

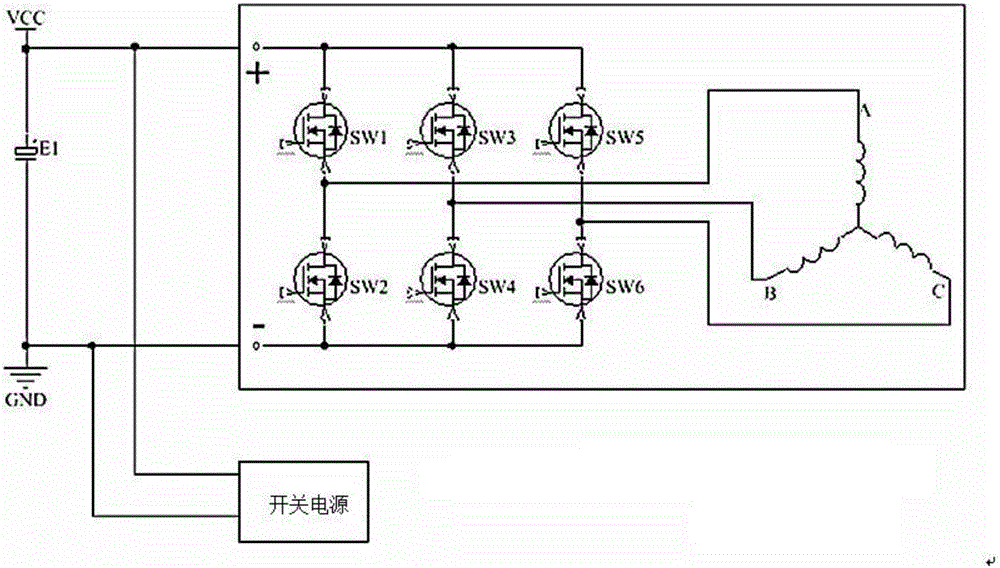

[0051] In the first embodiment of the present invention, a motor protection method, such as Figure 5 shown, including the following specific steps:

[0052] Step S101, setting a discharge brake circuit and a detection control circuit between the motor switching power supply and the motor.

[0053] Wherein, the bleed brake circuit includes a bleed resistor and a controlled switch;

[0054] The discharge brake circuit is connected in parallel between the positive pole and the negative pole of the motor power supply end;

[0055] The power detection end of the detection control circuit is connected with the switching power supply of the motor, and the control signal output end of the detection control circuit is connected with the controlled switch of the discharge brake circuit.

[0056] For example: the discharge brake circuit is connected in parallel between the positive pole and the negative pole of the motor power supply end; the discharge brake circuit includes: a series...

no. 2 example

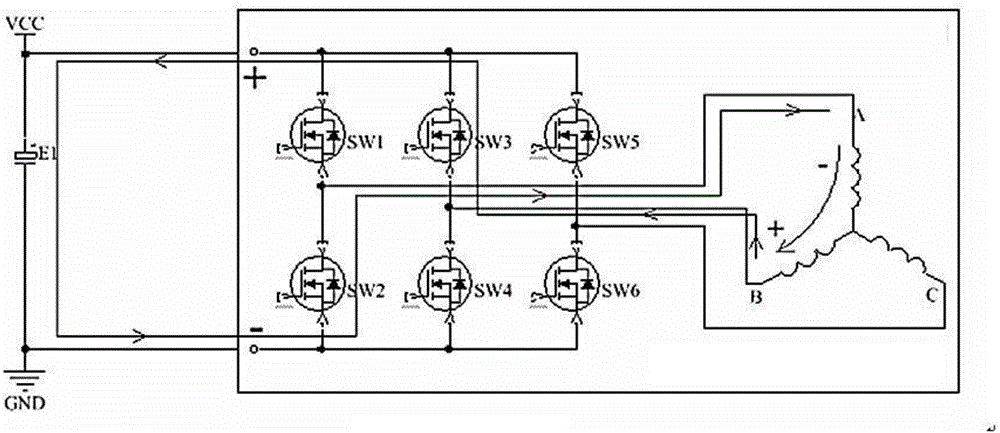

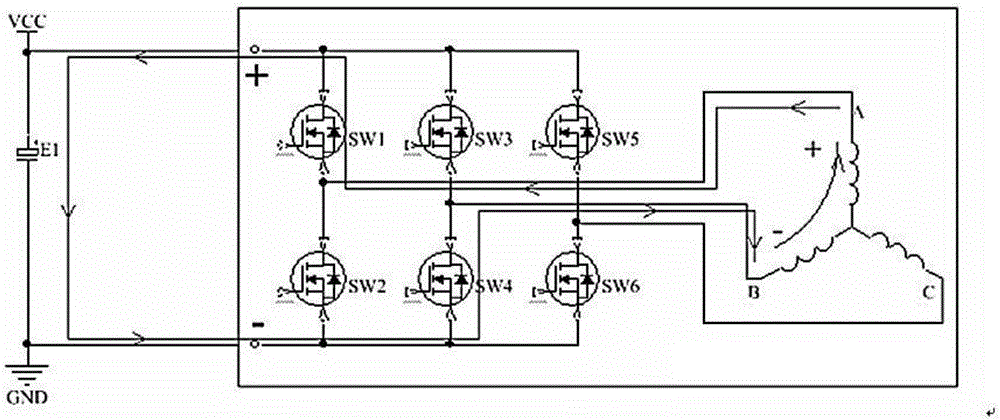

[0075] In the second embodiment of the present invention, a motor protection method, such as Image 6 with Figure 7 As shown, the method in this embodiment includes the following specific steps:

[0076] Step S201, setting a discharge brake circuit and a detection control circuit between the motor switching power supply and the motor.

[0077] Wherein, the bleed brake circuit includes a bleed resistor and a controlled switch;

[0078] The discharge brake circuit is connected in parallel between the positive pole and the negative pole of the motor power supply end;

[0079] The power detection end of the detection control circuit is connected with the switching power supply of the motor, and the control signal output end of the detection control circuit is connected with the controlled switch of the discharge brake circuit.

[0080] For example: if Image 6 As shown, the bleed brake circuit is connected in parallel between the positive pole and the negative pole of the mot...

no. 3 example

[0110] The third embodiment of the present invention, this embodiment introduces a motor, such as Figure 8 shown, including the following components:

[0111] Motor switching power supply, discharge brake circuit and detection control circuit;

[0112] The discharge brake circuit is connected in parallel between the positive pole and the negative pole of the motor power supply end;

[0113] The detection control circuit is respectively connected with the motor switching power supply and the discharge braking circuit;

[0114] The detection control circuit is used to control the discharge brake circuit based on the judgment result of whether the motor is powered off;

[0115] The discharge brake circuit is used to discharge the energy of the self-induced electromotive force and the counter electromotive force of the motor under the control of the detection control circuit.

[0116] Wherein, the bleed brake circuit includes a bleed resistor RL and a controlled switch K1;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com