Assembly-type building greenery wall

A prefabricated, green wall technology, applied in the direction of buildings, building components, building structures, etc., can solve the problem of pedestrians who are easy to get wet, and achieve the effect of avoiding excessive humidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

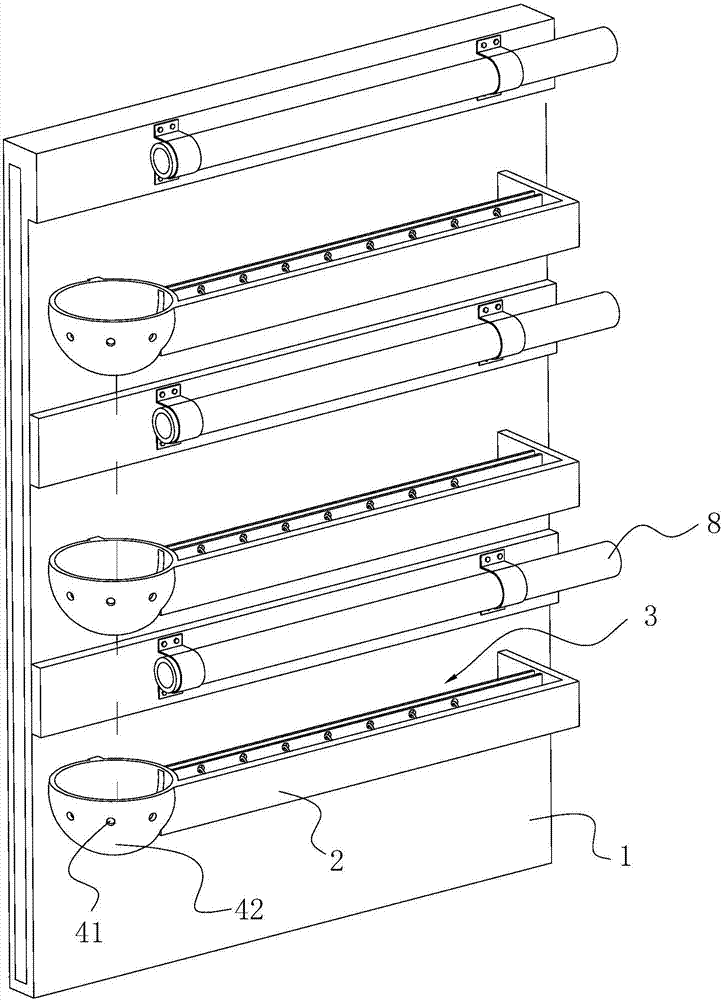

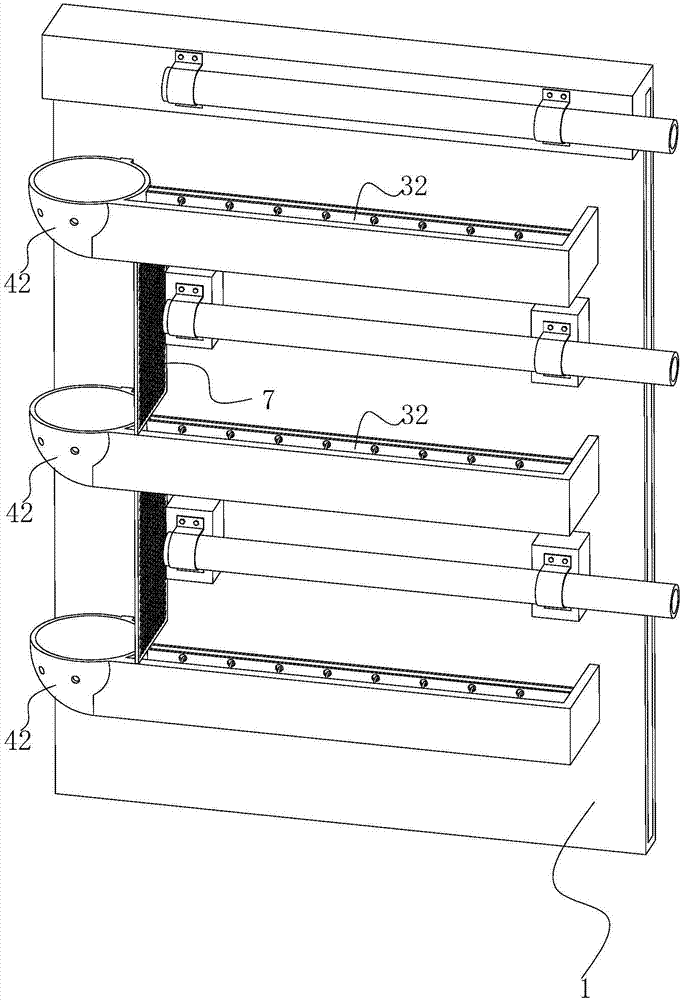

[0058] Embodiment 1, prefabricated building green wall, such as figure 1 As shown, a prefabricated wall panel 1 is included, and the wall panel 1 is hollow.

[0059] The side of the wall panel 1 is integrally formed with three connecting plates 2, which are poured and formed in the factory according to the mold. The connecting plates 2 are arranged horizontally, and the connecting plates 2 arranged up and down are all parallel to each other.

[0060] The connection plate 2 is provided with concave flower tanks 3, the flower tanks 3 are used for planting vegetation, and the upper end of each flower tank 3 is provided with a water spray pipe 8, and each water spray pipe 8 supplies water to each flower tank 3 independently.

[0061] One end of the planter 3 is provided with a guide surface 42 whose outer wall is hemispherical, and the guide surface 42 protrudes downward.

[0062] The lowest end of the diversion surface 42 is facing the opening of the flower tank 3 below, and the...

Embodiment 2

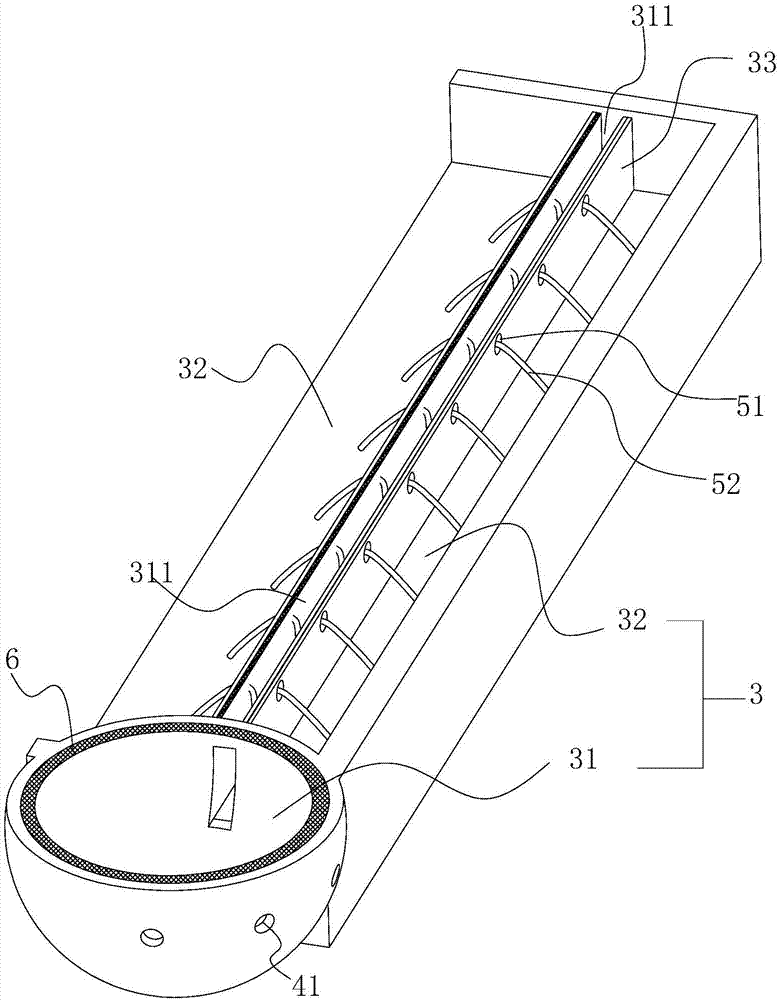

[0069] Embodiment 2, its difference with embodiment 1, such as figure 2 As shown, a partition 33 is arranged in the planter 3, and there are two partitions 33. Each partition 33 includes a straight plate and an arc-shaped plate, and the straight plate and the arc-shaped plate are fixedly connected to each other. There is a gap between the two partitions 33. , while the upper ends of the two curved plates are connected to each other. The partition 33 divides the planter 3 into a water tank 31 and a planting tank 32 , and the overflow hole 41 is placed on the wall of the water tank 31 ; and the height of the partition 33 is higher than that of the overflow hole 41 . The height of the planting tank 32, the height of the dividing plate 33, and the height of the overflow hole 41 are successively reduced so that the water flow can flow into the water tank 31 through the planting tank 32 to accumulate, and the water exceeding the volume of the water tank 31 can have an overflow hole...

Embodiment 3

[0075] Embodiment 3, a kind of prefabricated building green wall, its difference with embodiment 1 or embodiment 2, such as Figure 4 As shown, the guide surface 42 adopts a conical surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com