Honey collector

A collector and honey technology, applied in the field of honey collectors, can solve the problems of slow flow, sticking to the inner wall of the centrifuge, and inability to stir it, so as to achieve the effect of speeding up the collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below by means of specific embodiments:

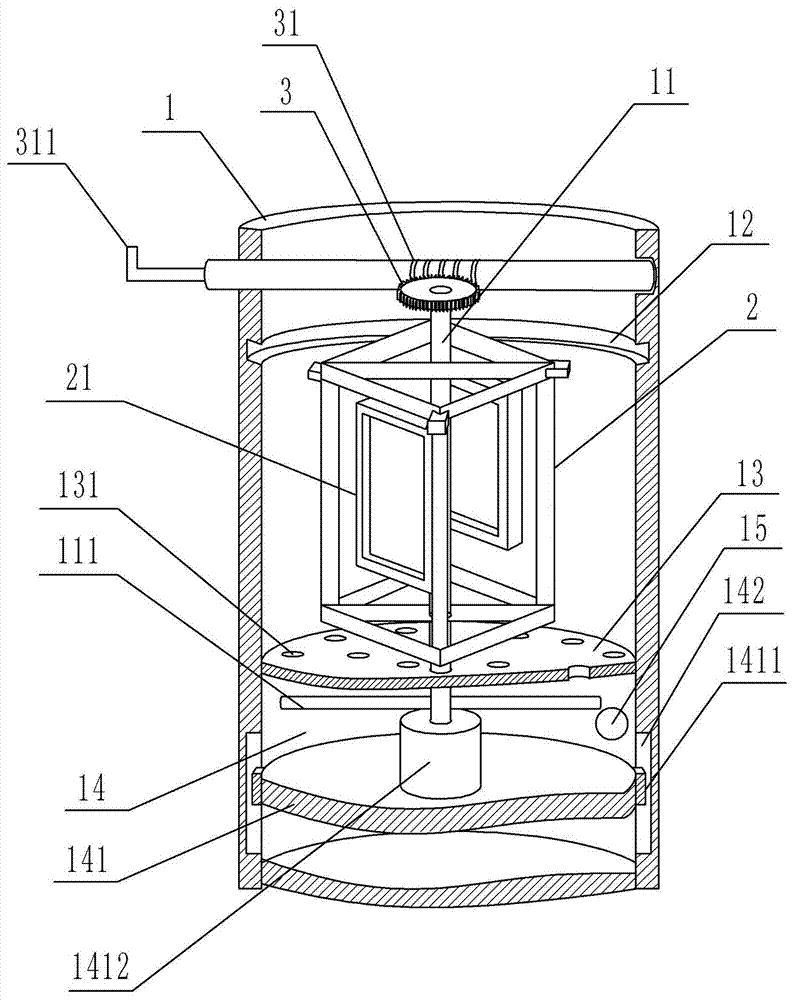

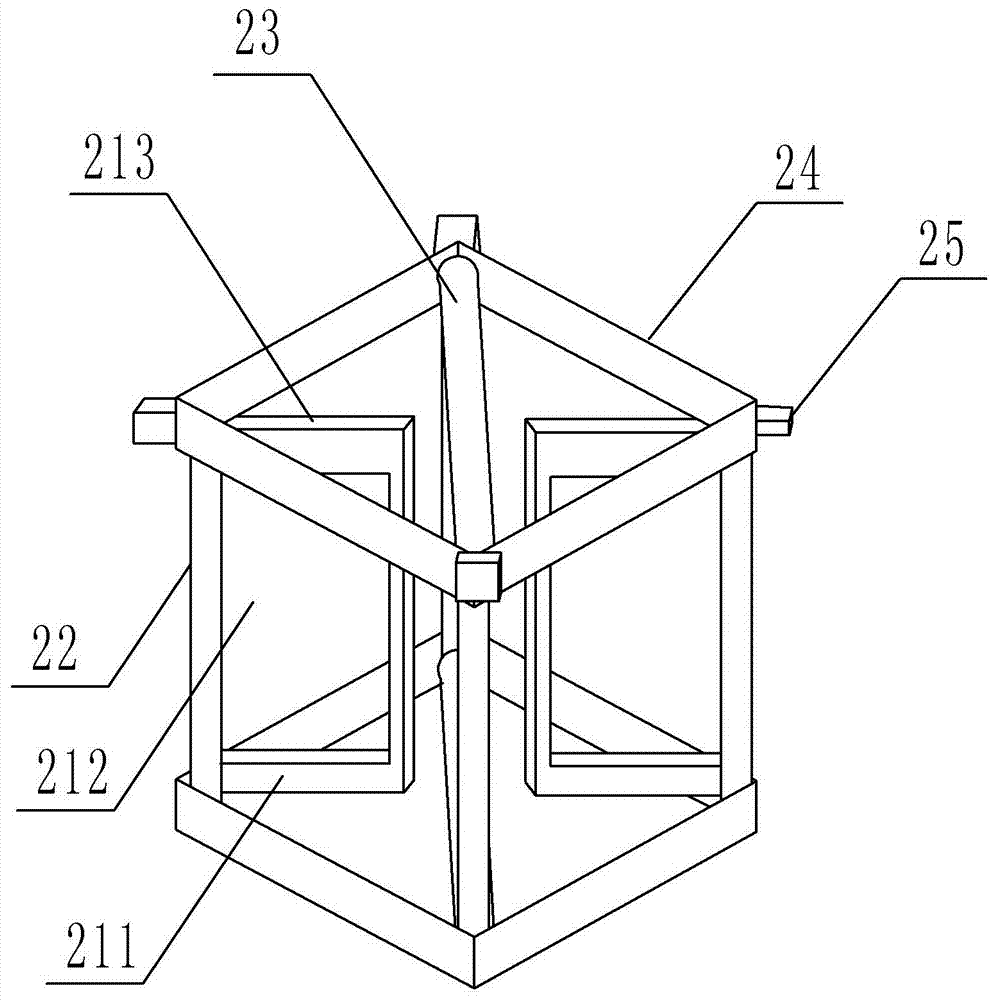

[0029] The reference numerals in the accompanying drawings of the description include: collection barrel 1, rotating rod 11, stirring rod 111, annular limiting groove 12, partition plate 13, suction hole 131, collecting chamber 14, piston 141, limiting protrusion 1411, Strip opening 142, connecting pipe 1412, pick-and-place opening 15, rotating part 2, placement frame 21, square frame body 211, ejection opening 212, insertion opening 213, fixing rod 22, connecting rod 23, square frame 24, limit bar 25, worm gear 3, worm screw 31, handle 311.

[0030] Such as figure 1 and figure 2 As shown, the honey collector includes a collection barrel 1, a rotating part 2 and a power part; the collecting barrel 1 is provided with a rotating rod 11 driven by the power part to rotate forward or reversely, and the inner wall of the collecting barrel 1 is provided with a handle for limi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com