High-speed wire steel heaping detection method

A detection method and high-speed wire technology, which can be used in length measuring devices, metal rolling, manufacturing tools, etc., can solve problems such as equipment or personnel injuries, and achieve stable signals and low design costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the embodiments and with reference to the accompanying drawings. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the direction in the figure, and the words "inner" and "outer ” refer to directions towards or away from the geometric center of a particular part, respectively.

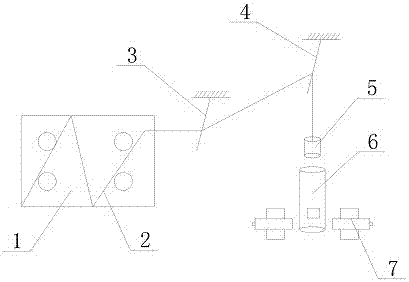

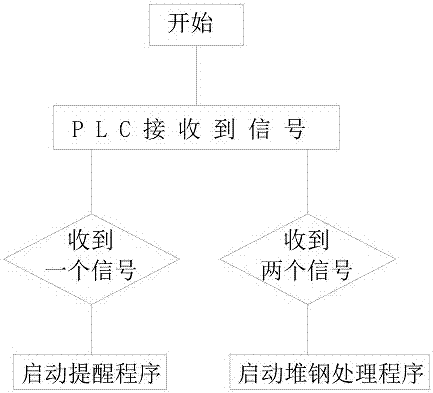

[0022] Combined with the accompanying drawings, a high-speed wire pile steel detection method uses a combination of double proximity switches to detect pile steel, including:

[0023] (1) Arrangement of the pull-rope fishing line: the pull-rope fishing line is wound around the roller ring of the rolling mill without any dead angle, and the lead-out line after the pull...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com