High-uniformity ink-jet printing method of large-area films and printing system

A technology of inkjet printing, printing system, applied in the direction of copying/marking method, printing, etc., to achieve the effect of achieving overall uniformity and easy printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

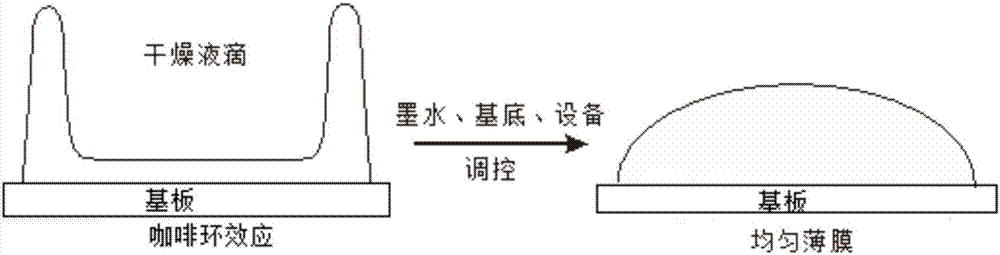

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below.

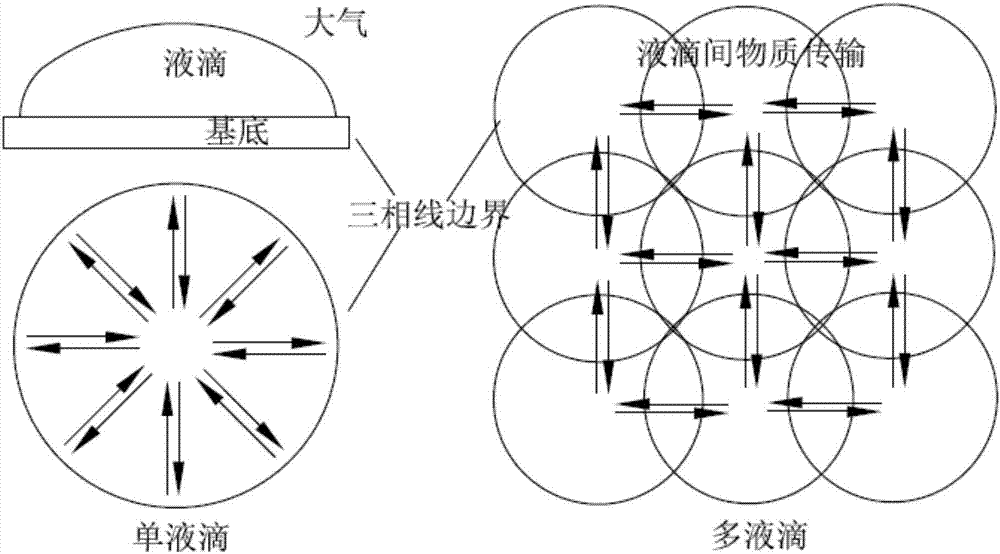

[0032] A large-area and high-uniformity thin-film inkjet printing method includes the following steps. Firstly, the substrate is cleaned and dried: the substrate is placed in a cleaning solution, the substrate is cleaned by ultrasonic vibration, and the substrate is dried after cleaning. Second, thin film printing: set printing parameters and graphics, and use a non-contact dot-jet printing system to print on the cleaned and dried substrate. The lower part of the substrate is heated while printing, and the printing ink uses low-temperature gelled ink. Finally, the film is dried: the lower part of the substrate continues to be heated to dry the film. , The boiling point of the low-temperature gelling ink solvent is 150-200°C, the viscosity is 6-10cp, the surface tension is 20-30dyne / cm, and the sintering temperature is 120-200°C. The gelation temperature is 80-90°C, and it can be filtered through a 0.22-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com