High-protectiveness inner box of packing box for ampoule bottle

A technology for injection bottles and protection, which is applied in the field of high-protection inner boxes for injection bottles, which can solve the problems of poor stability of fixed injection bottles, easy extrusion damage, and few protective measures, so as to achieve convenient transportation and improve quality , Improve the effect of load-bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

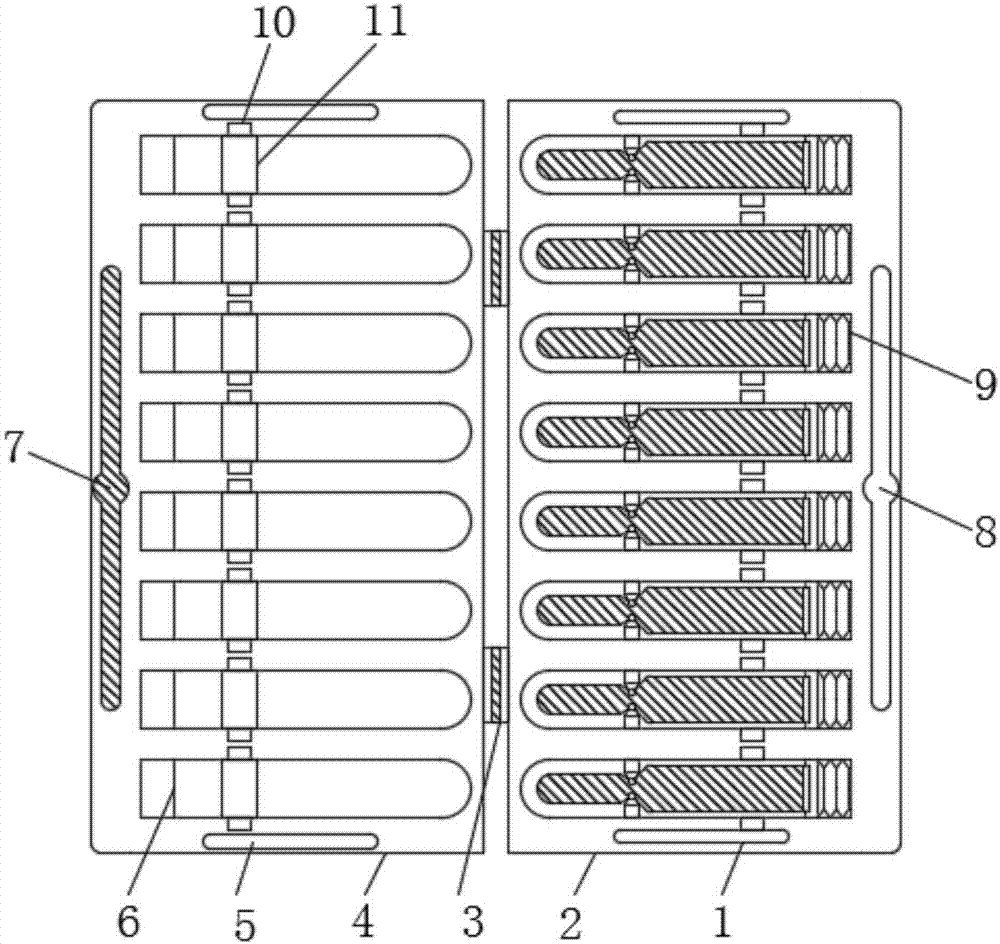

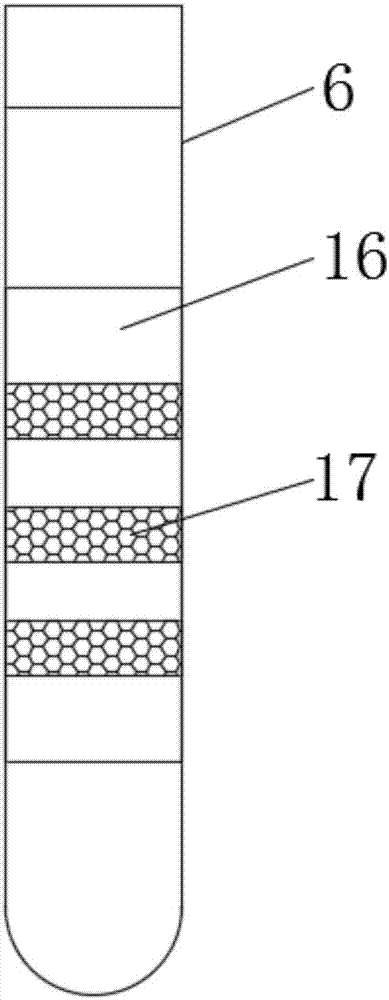

[0024] Embodiment one, with reference to figure 1 , a highly protective inner box of a packaging box for injection bottles, including an inner box body 2, the inner box body 2 is rotatably connected to the inner box cover 4 through a connecting hinge 3, and a foam shock-absorbing layer on the inner box body 2 There are eight injection bottle grooves 9 at the middle distance, fixed grooves 8 are formed on the outer frame of the inner box body 2, positioning grooves 1 are symmetrically opened on both sides of the inner box body 2, and the inner box cover 4 is equidistantly welded with eight injection bottle caps 6 connected to the groove 9 of the injection bottle, and the inner box cover 4 is welded with positioning protrusions 5 for embedded connection with the positioning groove 1 on both sides of the inner box cover. 4 The upper outer frame is welded with a positioning projection 7 for embedded connection with the fixing groove 8 .

Embodiment 2

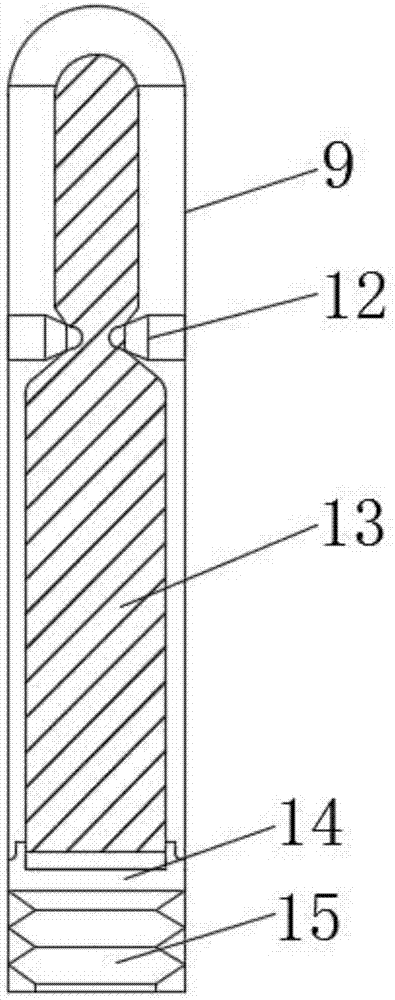

[0025] Embodiment two, refer to Figure 1-2 , the lower part of the injection bottle groove 9 is connected with a spacer 14 through a rubber telescopic spring 15, the injection bottle groove 9 is embedded with an injection bottle 13 through the spacer 14, and the inside of the injection bottle groove 9 is symmetrically welded on both sides of the neck of the injection bottle 13 Bottleneck pressing block 12 is arranged, and bottleneck pressing block 12 can fix the left and right sides of injection bottle 13, and rubber telescoping spring 15 is fixed to upper and lower sides by spacer 14.

Embodiment 3

[0026] Embodiment three, refer to figure 1 , the inner box body 2 is symmetrically embedded with support columns on both sides of the groove 9 of the injection bottle, and the support columns and support blocks 10 are symmetrical to each other about the midline connecting the inner box body 2 and the inner box cover 4, when the inner box When the lid 4 is closed, the support column and the support block 10 are embedded and connected, so that the connection position is more accurate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com