Welding rod packaging box

A packaging box and welding rod technology, which is applied in packaging, transportation and packaging, rigid containers, etc., can solve the problem of high moisture resistance of welding rods, and achieve the effects of good moisture resistance, simple structure, and easy use and portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, and the protection scope of the present invention will be defined more clearly.

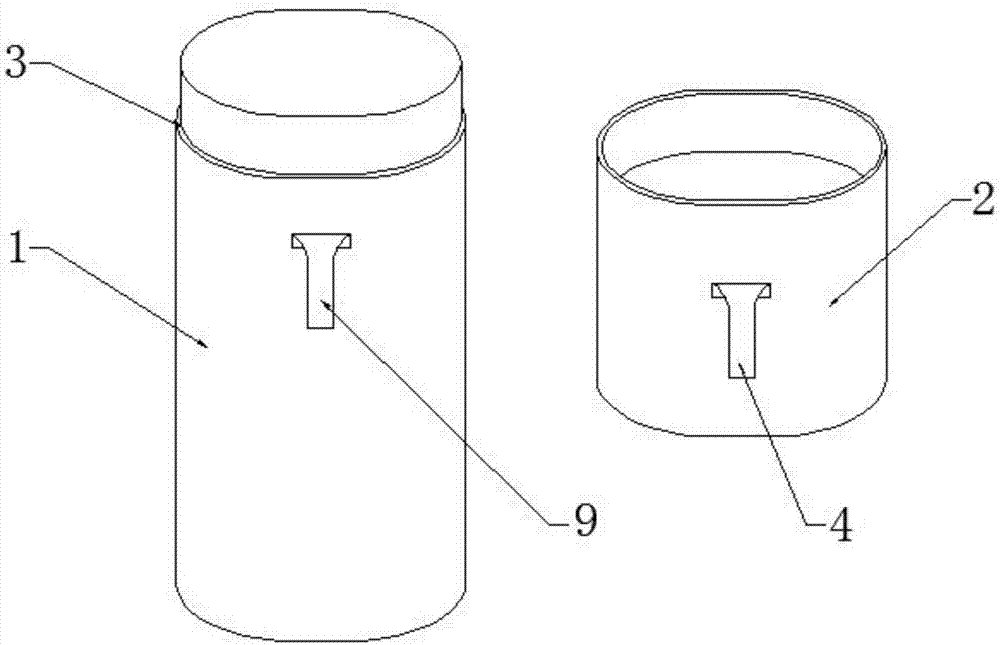

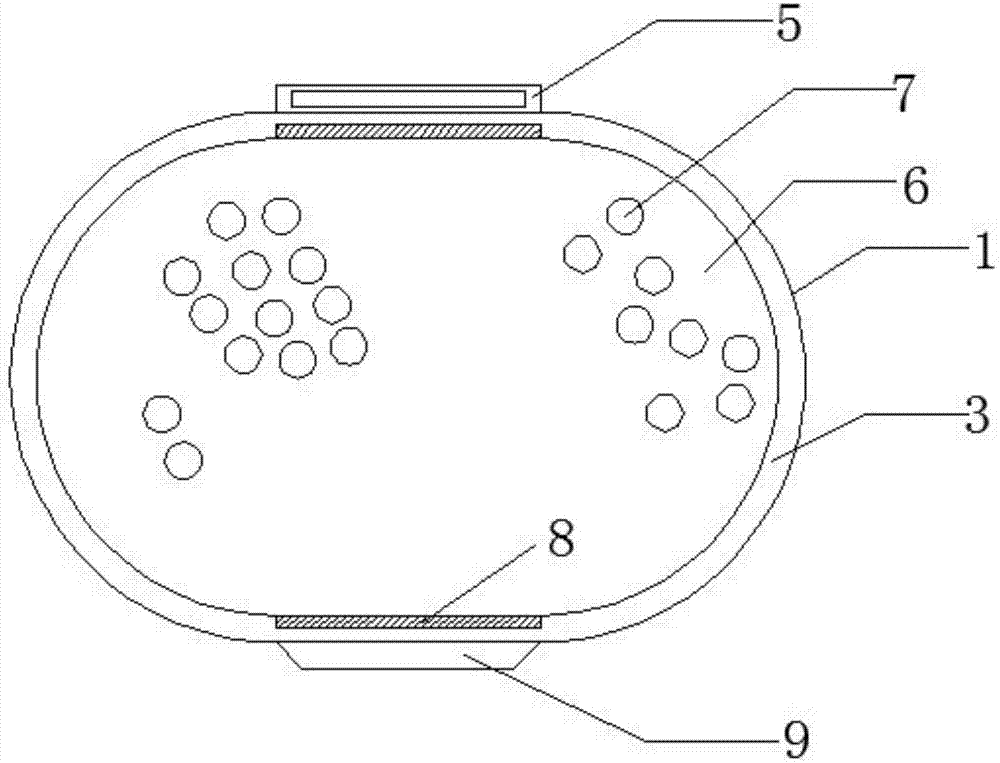

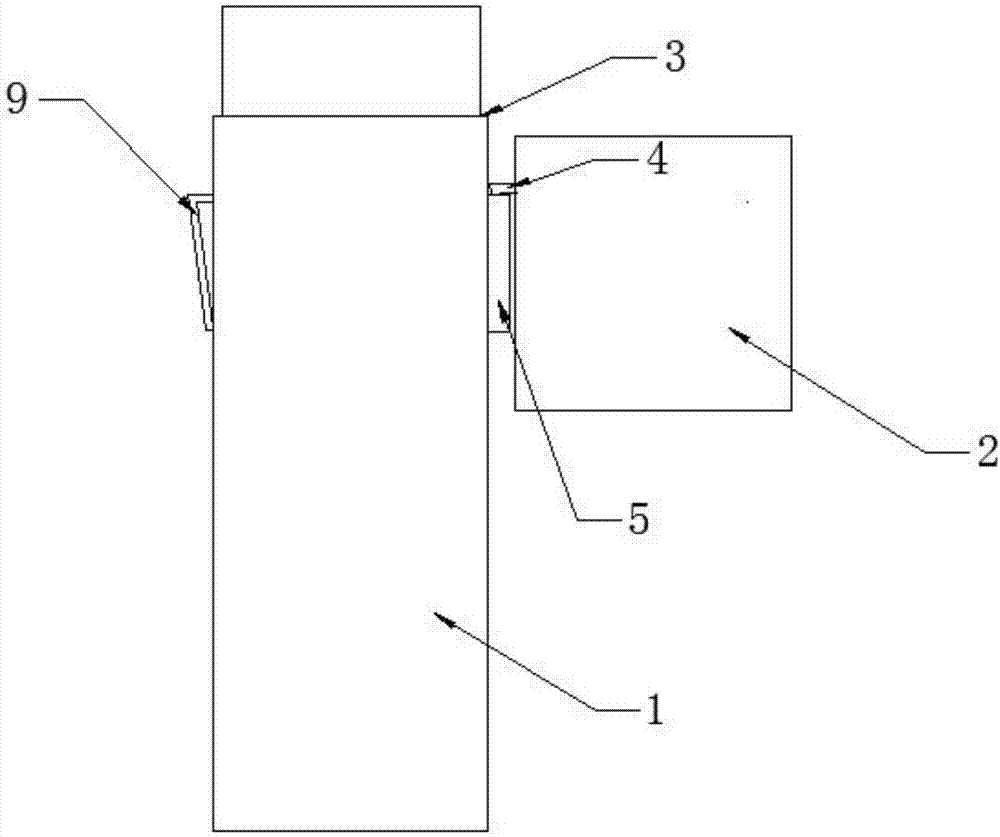

[0017] Refer to Figure 1-3 As shown, the present invention provides a welding rod packaging box, including a cover body 2, a box body 1 and a partition plate 6, characterized in that: the cover body 2 is provided with a clip I4 outside, and the inner wall of the cover body and the box body 1 The outer wall has a ring-shaped groove 3, and the two grooves 3 can be combined with each other. The box body 1 is provided with a clip II 9 and a fixed locking position 5, and the concave groove 8 is provided on the inner wall of the box body 1. A partition plate 6 is arranged inside, and the edge of the partition plate 6 fits with the inner edge of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com