Device capable of conducting judgment and safe, easy and convenient dust discharging on accident accumulated dust of dust remover

A dust collector and accident technology, which is applied in the field of simple ash discharge devices and dust removal equipment, can solve problems such as hidden dangers of ash removal system operation, misleading understanding of operation managers, and insufficient ash removal design and conveying capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

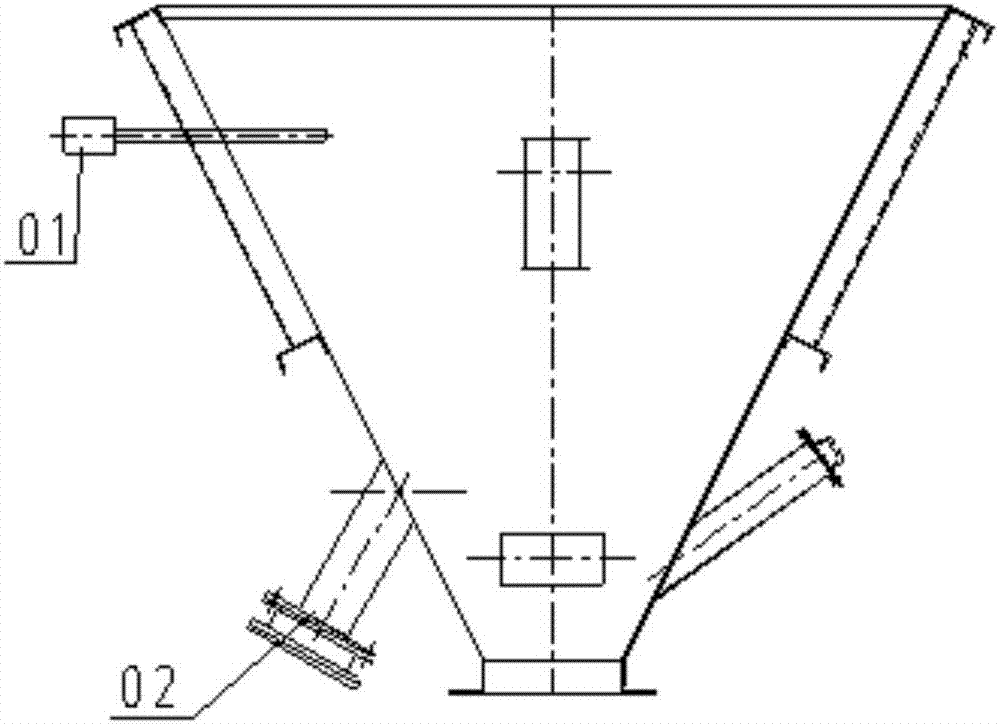

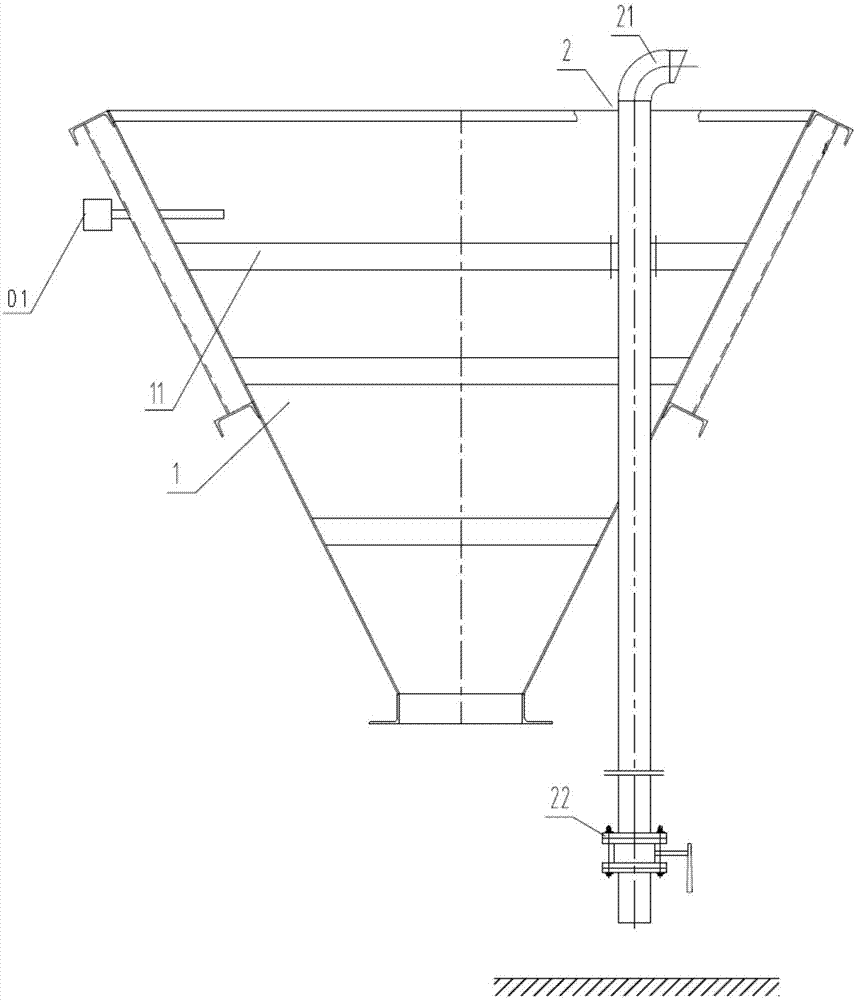

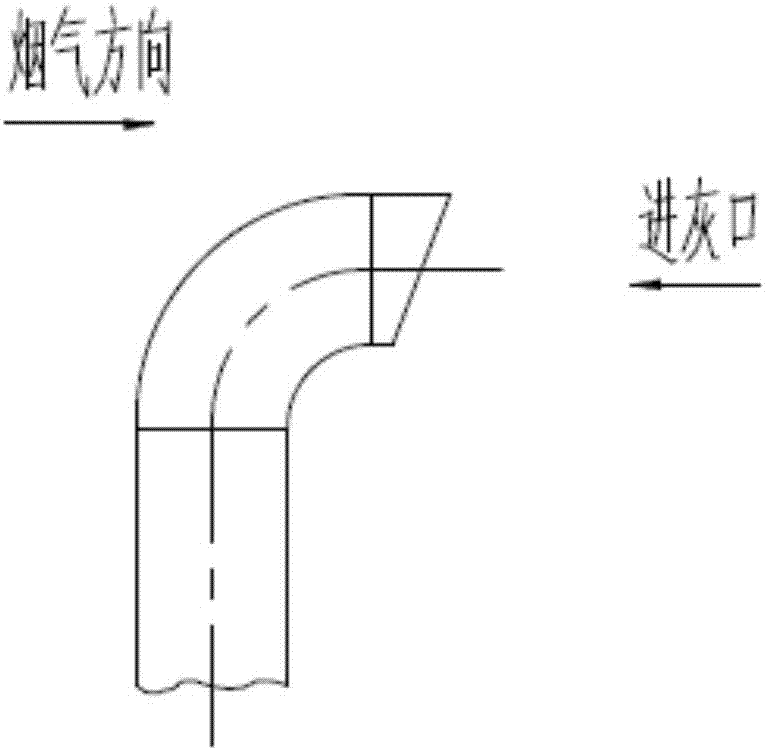

[0030] First explain the working principle of the present invention:

[0031] The ash hopper of the dust collector has the following characteristics due to its structure and working environment: First, when the dust collector is in operation, if the ash hopper is in an empty state without ash, the inside of the ash hopper will be in a negative pressure state, which means that If the hole connecting the ash hopper to the outside atmosphere is opened, the outside air will enter the inside of the ash hopper through the hole under the action of negative pressure. Secondly, when the ash hopper of the dust collector is in the state of ash accumulation, due to the high fluidity of the ash, which has a certain fluid property, the tension of the ash makes the ash spray outward from the hole where the ash hopper is connected to the external atmosphere, and the ash above the hole The higher the ash accumulation, the greater the ash ejection power.

[0032] Dust storage in the normal ash...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com