High-performance powdery emulsion explosive for three-level coal mine and preparation method of high-performance powdery emulsion explosive

A technology of powdery emulsion explosives and emulsion explosives, which is applied in the direction of explosives, etc., can solve problems such as not very outstanding explosive performance, reduced explosive performance, and shortened shelf life of explosives, so as to reduce the free accumulation of bubbles, improve safety, and good explosive performance Effect on storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] This embodiment provides a high-performance tertiary coal mine powdery emulsion explosive, which comprises the following components in parts by mass:

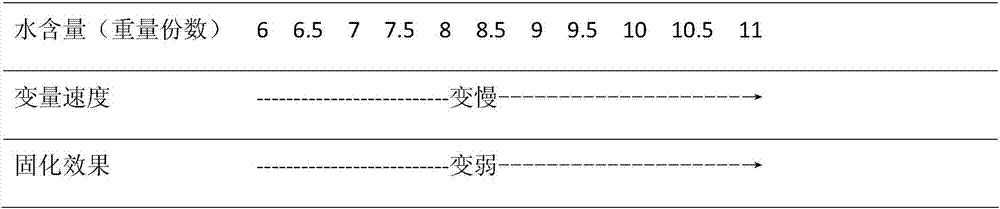

[0066] Ammonium nitrate: 70.0 parts, sodium nitrate: 7.0 parts, water: 7.5 parts, sodium chloride: 6.0 parts, microcrystalline wax: 1.2 parts, hydrocarbons: 3.5 parts, sensitizer: 0.3 parts, emulsifier: 2.0 parts .

[0067] The sensitizer is a mixture of N,N-dinitrosopentamethylenetetramine and water, in terms of mass ratio N,N-dinitrosopentamethylenetetramine:water=1:2; The compound is often three line oil.

[0068] The preparation method of emulsifier is as follows:

[0069] The emulsifier includes the following components by mass percentage: high viscosity emulsifier T155: 60%, polyacrylamide: 5%, soybean lecithin: 35%;

[0070] Mix high-viscosity emulsifier T155 and polyacrylamide evenly and heat to 75°C, then add soybean lecithin, stir at 75°C for 3 hours to obtain emulsifier.

[0071] The preparation method of ...

Embodiment 2

[0081] This embodiment provides a high-performance tertiary coal mine powdery emulsion explosive, which comprises the following components in parts by mass:

[0082] Ammonium nitrate: 80.0 parts, sodium nitrate: 11.0 parts, water: 11.0 parts, sodium chloride: 10.0 parts, microcrystalline wax: 1.5 parts, hydrocarbons: 4.8 parts, sensitizer: 0.6 parts, emulsifier: 2.5 parts .

[0083] The sensitizer is a mixture of N,N-dinitrosopentamethylenetetramine and water, in terms of mass ratio N,N-dinitrosopentamethylenetetramine:water=1:2; The compound is a vacuum distillate.

[0084] The preparation method of emulsifier is as follows:

[0085] The emulsifier includes the following components by mass percentage: high viscosity emulsifier T155: 60%, polyacrylamide: 5%, soybean lecithin: 35%;

[0086] Mix high-viscosity emulsifier T155 and polyacrylamide evenly and heat to 75°C, then add soybean lecithin, stir at 75°C for 3 hours to obtain emulsifier.

[0087] The preparation method o...

Embodiment 3

[0094] This embodiment provides a high-performance tertiary coal mine powdery emulsion explosive, which comprises the following components in parts by mass:

[0095] Ammonium nitrate: 75 parts, sodium nitrate: 10 parts, water: 9 parts, sodium chloride: 8 parts, microcrystalline wax: 1.4 parts, hydrocarbons: 4.1 parts, sensitizer: 0.4 parts, emulsifier: 2.2 parts .

[0096] The sensitizer is a mixture of N,N-dinitrosopentamethylenetetramine and water, in terms of mass ratio N,N-dinitrosopentamethylenetetramine:water=1:2; The compound is a mixture of decompression wax paste and heavy deasphalted oil.

[0097] The preparation method of emulsifier is as follows:

[0098] The emulsifier includes the following components by mass percentage: high viscosity emulsifier T155: 60%, polyacrylamide: 5%, soybean lecithin: 35%;

[0099] Mix high-viscosity emulsifier T155 and polyacrylamide evenly and heat to 75°C, then add soybean lecithin, stir at 75°C for 3 hours to obtain emulsifier. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com