A kind of preparation method of acid anhydride modified biphenyloxetane acrylate prepolymer

A technology of biphenyl oxetane acrylate and biphenyl oxetane, which is applied in the field of ultraviolet light curing, can solve the problem of reducing the overall performance of epoxy acrylate, the decrease in hardness and chemical resistance, light aging resistance and resistance to light. Problems such as poor xanthosis, low toxicity and mutagenicity, less irritation to glasses and skin, and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

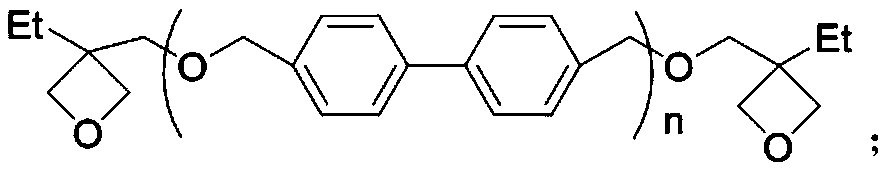

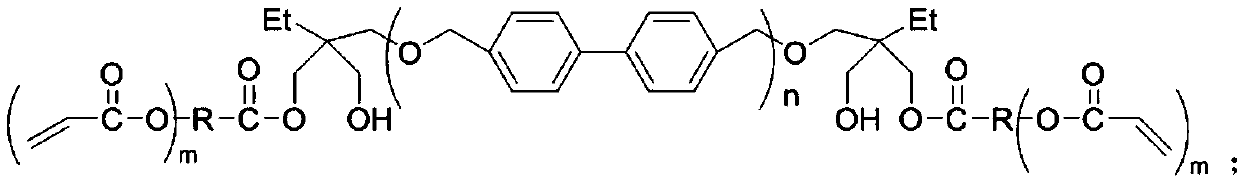

[0035] This example provides a method for preparing an anhydride-modified biphenyloxetane acrylate prepolymer. The steps include: adding 98g of maleic anhydride and 116g of hydroxyethyl acrylate to the flask, 0.04g 4-Dimethylaminopyridine, 0.17g of p-toluenesulfonic acid, 0.21g of p-hydroxyanisole, heated and stirred at 60°C for 4 hours to obtain the semi-addition of intermediate hydroxyacrylate and cyclic anhydride things. Add 410g of biphenyloxetane to the flask, add 3.12g of benzyltriethylammonium chloride, 3.12g of 2,6-di-tert-butyl-4-methylphenol, and react at 80°C After 5 hours, after the reaction was completed, vacuum degassing treatment was performed at 75° C. to obtain the final product with a viscosity of 620 mpa.s (60° C.). The product structure is:

[0036]

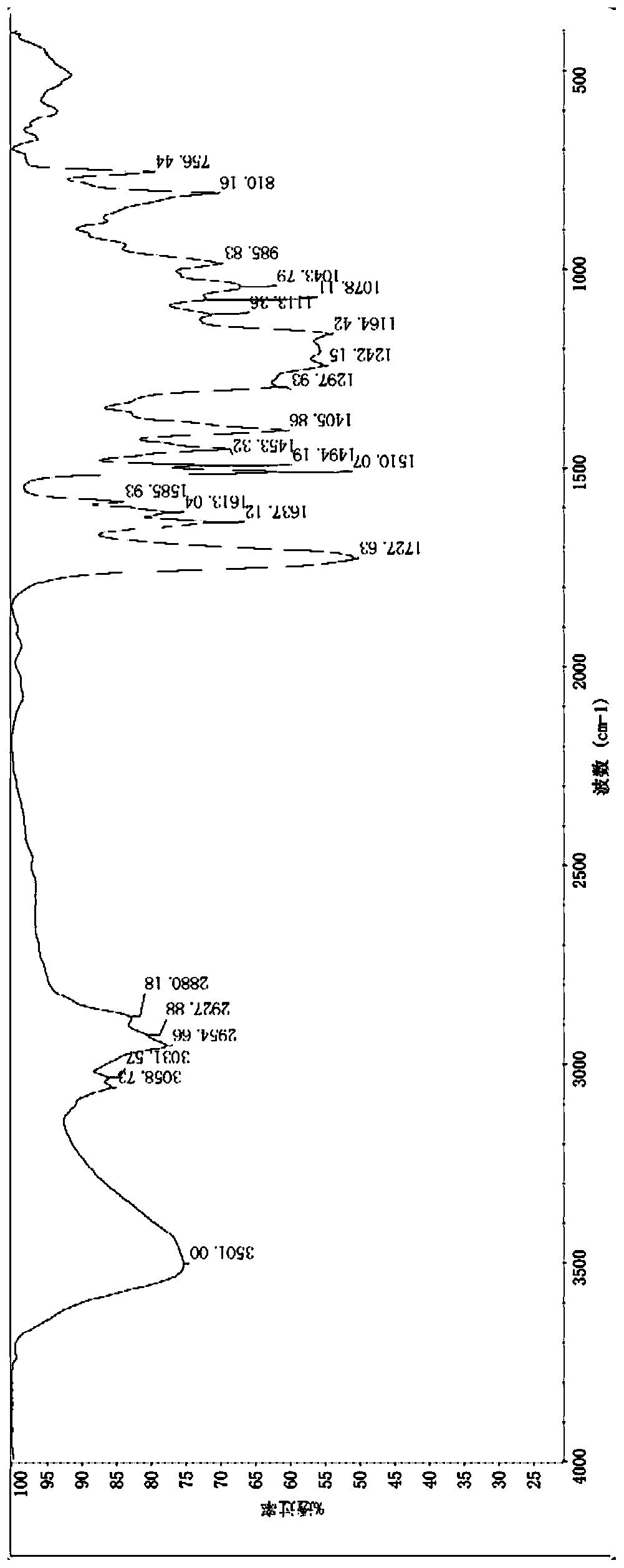

[0037] The infrared absorption spectrum of the product is attached figure 1 As shown in the figure, it can be seen from the figure that its molecular structure contains groups such as hydroxyl, double bo...

Embodiment 2

[0042] This example provides a method for preparing an anhydride-modified biphenyloxetane acrylate prepolymer. The steps include: adding 148g of phthalic anhydride and 130g of hydroxypropyl acrylate to a flask, 0.06g 4-Dimethylaminopyridine, 0.23g of p-toluenesulfonic acid, 0.28g of p-hydroxyanisole, heated and stirred at 70°C for 3h to obtain a semi-adduct of hydroxyacrylate and cyclic anhydride. The biphenyl oxetane of 410g is joined in the flask again, and add 2.06g benzyltriethylammonium bromide, 2.06g p-hydroxyanisole, and react at 85 ℃ for 4 hours, after the reaction finishes, Vacuum degassing treatment at 80°C to obtain the final product with a viscosity of 1630mpa.s (60°C).

Embodiment 3

[0044]This example provides a method for preparing an anhydride-modified biphenyloxetane acrylate prepolymer. The steps include: adding 178g of methylnadic anhydride and 144g of hydroxybutyl acrylate to the flask, 0.09g 4-Dimethylaminopyridine, 0.23g of p-toluenesulfonic acid, 0.32g of p-hydroxyanisole, heated and stirred at 60°C for 4h to obtain a semi-adduct of hydroxy acrylate and cyclic anhydride. Then 410g of biphenyl oxetane was added to the flask, and 3.66g of tetramethylammonium chloride, 1.66g of p-hydroxyanisole and 2.0g of 2,6-di-tert-butyl-4-methyl Base phenol, and react at 90°C for 3 hours. After the reaction, vacuumize and defoam at 85°C to obtain the final product with a viscosity of 1310mpa.s (60°C).

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com