Production process of triallyl cyanurate

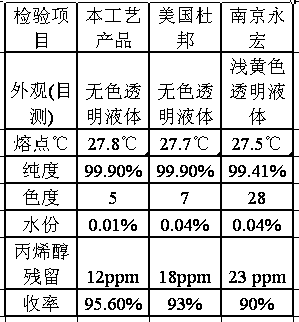

A technology of triallyl ester and cyanuric acid, which is applied in the direction of organic chemistry, can solve the problems of complex production process, large environmental pollution, high product cost, etc., and achieve the goal of reducing three wastes discharge, increasing product yield and reducing production steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] In a 1000L enamel reaction kettle with an external heat exchange circuit composed of a cooler and a circulation pump, initially charge 596.0kg (7800mol) of chloropropene with an excess of 30%; start the stirring, start the cooling circuit with brine, and put Allyl chloride was cooled to 0°C. Then start to add a total of 396.0 kg (2000mol) of trisodium cyanurate, add slowly through a vibrating feeder, rapidly dissolve and react to release heat, control the temperature at 5-10°C, and generate triallyl cyanurate and sodium chloride. The time is about 60 minutes. For complete conversion, the cooling circuit equipped with brine was closed, and hot water at 40° C. was introduced into the reactor jacket to raise the temperature of the reaction liquid to 40° C., and the stirring was continued for 20 minutes. After stabilizing the triallyl cyanurate with 100ppm of hydroquinone monomethyl ether, turn on the water jet vacuum, and at a temperature of 35°C, distill and recover the ...

Embodiment 2

[0039] In a 1000L enamel reaction kettle with an external heat exchange circuit composed of a cooler and a circulating pump, initially charge 550.0kg (7200mol) of chloropropene with an excess of 20%; start the stirring, start the cooling circuit with brine, and put Allyl chloride was cooled to 0°C. Then start to add a total of 396.0 kg (2000mol) of trisodium cyanurate, add slowly through a vibrating feeder, rapidly dissolve and react to release heat, control the temperature at 5-10°C, and generate triallyl cyanurate and sodium chloride. The time is about 60 minutes. For complete conversion, the cooling circuit equipped with brine was closed, and 42°C hot water was introduced into the reactor jacket to raise the temperature of the reaction liquid to 38°C, and the stirring was continued for 20 minutes. After stabilizing the triallyl cyanurate with 100ppm of hydroquinone monomethyl ether, turn on the water jet vacuum, and at a temperature of 39°C, distill and recover the unreact...

Embodiment 3

[0041] In a 1000L enamel reaction kettle with an external heat exchange circuit composed of a cooler and a circulating pump, initially charge 643.0kg (8400mol) of chloropropene with an excess of 40%; start stirring, start the cooling circuit with brine, and put Allyl chloride was cooled to 0°C. Then start to add a total of 396.0 kg (2000mol) of trisodium cyanurate, add slowly through a vibrating feeder, rapidly dissolve and react to release heat, control the temperature at 5-10°C, and generate triallyl cyanurate and sodium chloride. The time is about 60 minutes. For complete conversion, the cooling circuit equipped with brine was closed, and 45°C hot water was introduced into the jacket of the reaction kettle to raise the temperature of the reaction liquid to 40°C, and the stirring was continued for 20 minutes. After stabilizing the triallyl cyanurate with 100 ppm of hydroquinone monomethyl ether, turn on the water jet vacuum, and at a temperature of 40° C., distill and recov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com