A process for pressurized catalytic synthesis of high-purity dodecylnitrile

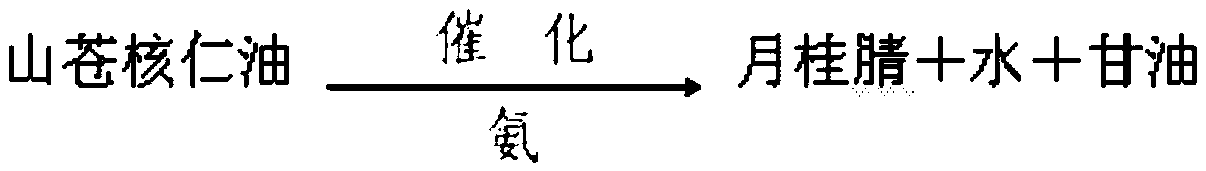

A high-purity technology of dodecyl nitrile, which is applied in the field of pressurized catalytic synthesis of high-purity dodecyl nitrile, can solve the problems of many intermediate products, low product purity, and high cost, and achieve the value of large-scale industrialization promotion, high product purity, and low cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

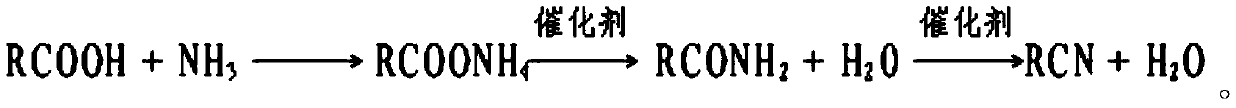

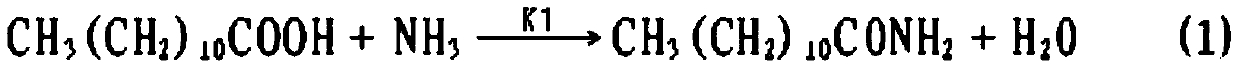

Method used

Image

Examples

Embodiment 1

[0031] Put the raw material 1kg of lauric acid and 0.5% catalyst into the ammoniation reactor, heat up and melt at 170°C to pass through the ammonia: when starting to pass through the ammonia, pay attention to the flux of ammonia gas, probably controlled at about 35L / min, operate according to the time course, and control the temperature at 170°C in the early stage -190℃, pressure 1kg / cm 2 , time 1.5 hours; later stage temperature control 270-280 ℃, pressure 2kg / cm 2 , time 3 hours, 4.5 hours after the end of the reaction, sampling analysis (product purity detection adopts gas chromatography).

[0032] Catalysts are metal salts of zinc and molybdenum. The metal salt is sulfate, wherein the molar ratio of the metal salt of zinc to the metal salt of molybdenum is 1:1.

Embodiment 2

[0034] Put the raw material 1kg of lauric acid and 0.5% catalyst into the ammoniation reactor, heat up and melt at 170°C for ammonia flow: pay attention to the ammonia flux when starting the ammonia flow, and control it at about 40L / min, operate according to the time course, and control the temperature at 180°C in the early stage -190℃, pressure 1kg / cm 2 , time 1.5 hours; later stage temperature control 270-280 ℃, pressure 1.5kg / cm 2 , time 2.5 hours, 4.5 hours reaction finishes, sampling analysis (product purity detection adopts gas chromatography).

[0035] Catalysts are metal salts of zinc and molybdenum. The metal salt is phosphate, wherein the molar ratio of the metal salt of zinc to the metal salt of molybdenum is 1:3.

Embodiment 3

[0037] Put the raw material 1kg of lauric acid and 1% catalyst into the ammoniation reactor, heat up and melt at 170°C for ammonia flow: pay attention to the ammonia flux when starting the ammonia flow, control it at about 35L / min, operate according to the time course, and control the temperature at 180°C in the early stage -190℃, pressure 1kg / cm 2 , time 1 hour; later stage temperature control 270-280 ℃, pressure 2kg / cm 2 , time 2.5 hours, 3.5 hours after the end of the reaction, sampling analysis (product purity detection adopts gas chromatography).

[0038] Catalysts are metal salts of zinc and molybdenum. The metal salt is sulfate, wherein the molar ratio of the metal salt of zinc to the metal salt of molybdenum is 1:2.

[0039] The specific performance test is shown in Table 2.

[0040] Table 2

[0041] Example 1 Example 2 Example 3 melting point 3.7℃ 3.6℃ 3.8℃ content 98.5% 99.2% 98.5%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com