Starch-based paperboard adhesive and preparation method thereof

An adhesive and starch technology, applied in the direction of amylose/pullulan adhesives, adhesive types, non-polymer adhesive additives, etc., can solve the unstable performance of adhesives and unstable performance of starch adhesives and other problems, to achieve the effect of reducing glue making steps, improving the reliability and stability of glue making, and reducing weighing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The starch-based cardboard adhesive of the present invention includes starch, a solvent for dissolving starch and preparing starch slurry, lye, and borax, and the lye adjusts the pH value of the starch slurry to 8-9; the starch is composed of amylose, amylopectin Composition of starch, the quality of the amylose accounts for 15% to 28% of the total starch mass, the quality of the amylopectin accounts for 72% to 85% of the total starch mass; the lye is caustic soda with a concentration of 33.3%; The quality of starch accounts for 22%-25% of the total mass of the finished cardboard adhesive, the mass ratio of borax to starch is 0.007-0.012:1.000, and the mass ratio of lye to starch is 0.061-0.071:1.000 .

[0027]Starch includes amylose and amylopectin. During the bonding process, due to the penetrating power of amylose molecules and the gripping force of amylopectin molecules whose shape is like branches, when the starch granules penetrate into the surface paper and Afte...

Embodiment 2

[0032] The quality of the starch accounts for 25% of the finished cardboard adhesive, the mass ratio of the lye to the starch is 0.066:1.000, and the mass ratio of the borax to the starch is 0.010:1.000. The present invention combines the existing glue production amount, glue production time and adhesive parameters to optimize the best ratio, obtain the most cost-effective finished cardboard adhesive, and make the finished cardboard adhesive present a high solid content of 25%, 16 The characteristics of low viscosity within seconds and low gelatinization temperature of 53°C can effectively save energy and improve production efficiency.

Embodiment 3

[0034] The preparation method of starch-based cardboard adhesive comprises the following steps:

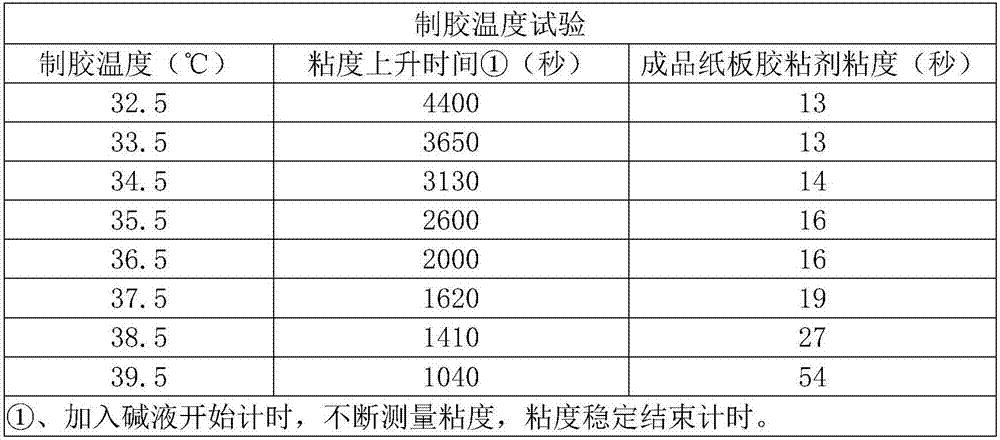

[0035] S1. Weighing the starch, dissolving the starch in a solvent at 36-38°C and stirring to prepare a starch slurry;

[0036] S2. Add lye to the starch slurry in step S1, the temperature of the starch slurry is 36-38°C, adjust the pH value of the starch slurry to 8-9 to prepare a weakly alkaline starch slurry, then continue to heat up and stir the starch slurry to The gelatinization temperature of the starch slurry is used to prepare the starch slurry;

[0037] S3. Cool the starch paste obtained in step S2 to 30° C., add borax, and stir to obtain a finished cardboard adhesive.

[0038] The solvent is a water solvent, and the lye is a caustic soda solution with a concentration of 33.3%.

[0039] In the present invention, a slight excess of lye is added at one time, so that the starch slurry is weakly alkaline, and the gelatinization reaction of starch under the action of lye is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com