Patents

Literature

43 results about "Ethynodiol Diacetate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The diacetate salt form of ethynodiol, a semi-synthetic progestational hormone agonist. Ethynodiol diacetate binds to cytoplasmic progesterone receptors in the reproductive system and subsequently activates progesterone receptor mediated gene expression. As a result of the negative feedback mechanism, luteinizing hormone (LH) release is inhibited, which leads to an inhibition of ovulation and an alteration in the cervical mucus and endometrium. In addition, ethynodiol diacetate has weak oestrogenic and androgenic properties.

Vinyl acetate production process

InactiveUS20110087047A1Organic compound preparationPreparation by transesterificationAcetic acidEthynodiol Diacetate

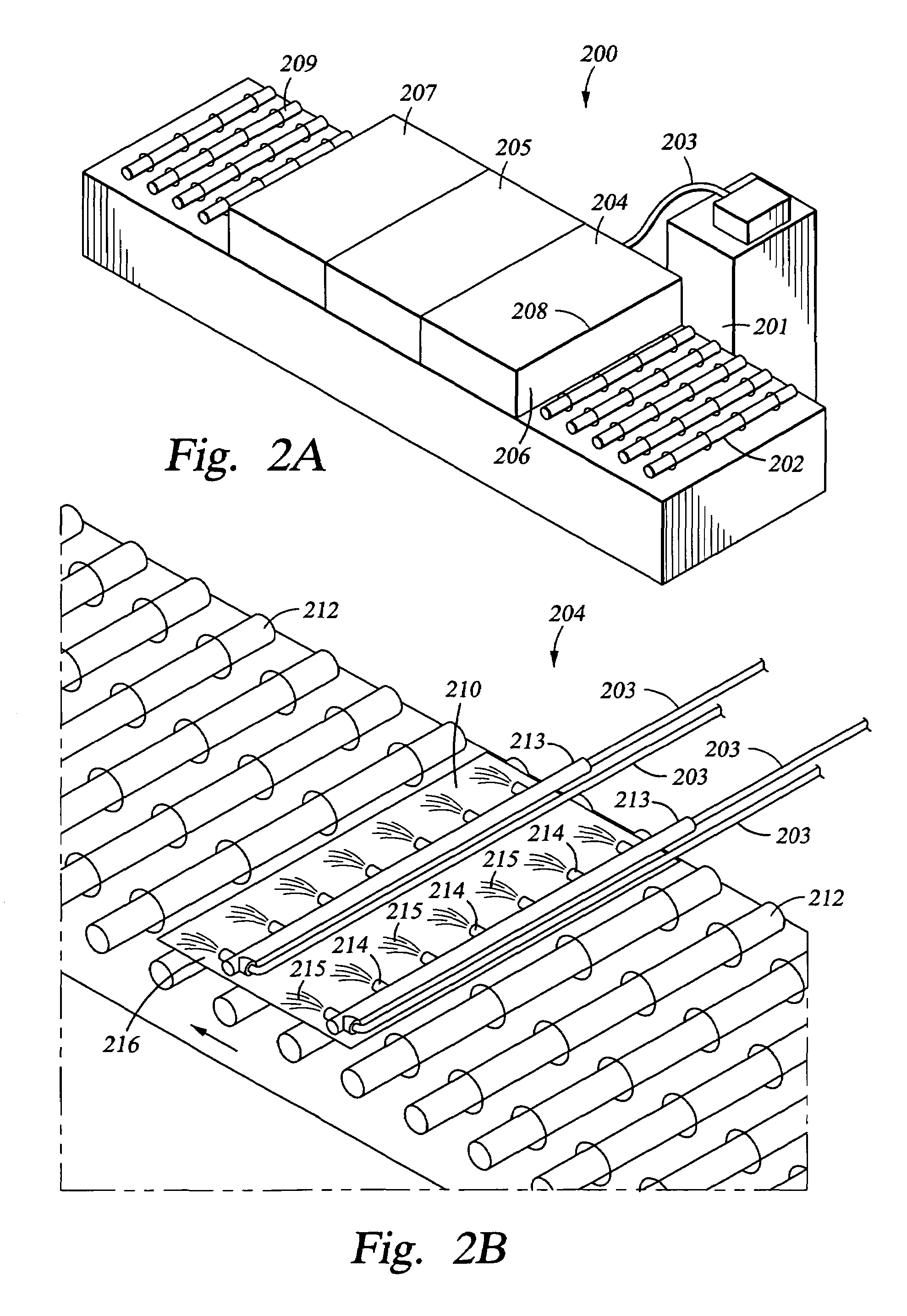

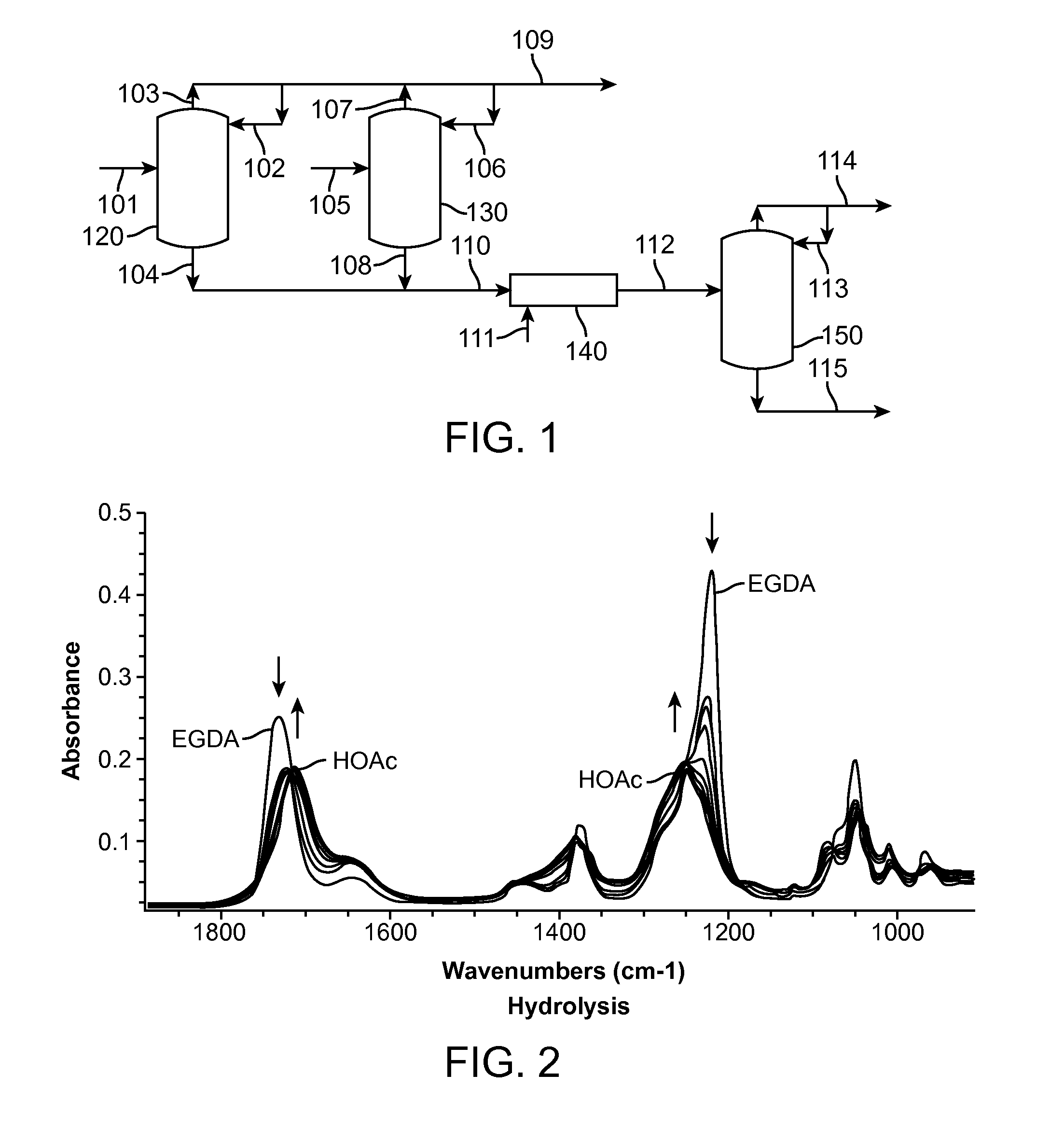

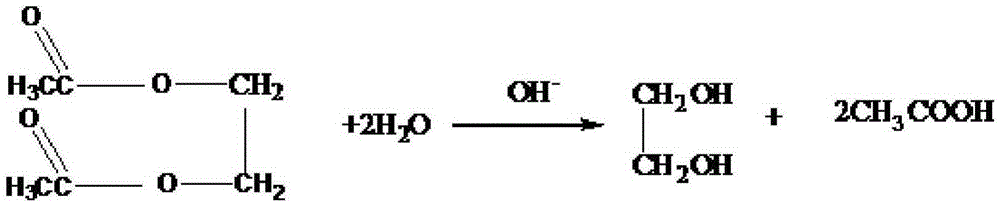

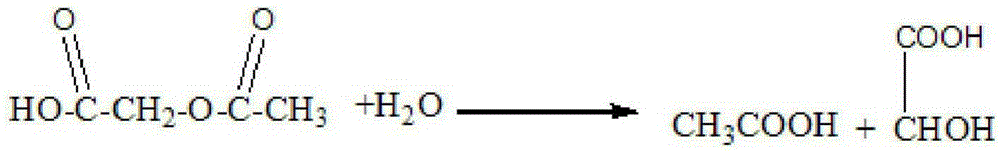

A process for the production of vinyl acetate is disclosed. The process comprises reacting ethylene, acetic acid, and oxygen in the presence of a catalyst to produce a reaction mixture comprising vinyl acetate, ethylene, carbon dioxide, acetic acid and ethylene glycol diacetate. The reaction mixture is separated to a gas stream comprising ethylene, oxygen, and carbon dioxide and a crude vinyl acetate stream comprising vinyl acetate, acetic acid and ethylene glycol diacetate. An ethylene glycol diacetate stream, which comprises at least 50 wt % of ethylene glycol diacetate, is isolated from the crude vinyl acetate stream and hydrolyzed to recover acetic acid. Recovered acetic acid may be recycled to the acetoxidation reaction.

Owner:LYONDELL CHEM TECH LP

Conductive composition

ActiveUS7771627B2Conductive materialNon-conductive material with dispersed conductive materialParticulatesSilver carbonate

Owner:FUJIKURA LTD +1

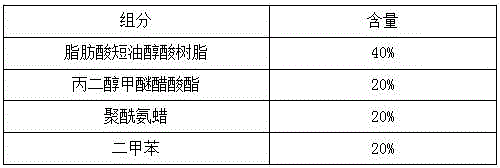

High-fullness and shock-resistance polyurethane matte top-coat paint

The invention discloses high-fullness and shock-resistance polyurethane matte top-coat paint. Castor oil alkyd resin, 20% of chlorine vinegar resin, wax powder and matte powder are prepared to a component A; TDI addition curing agent L-75, TDI tripolymer curing agent 1451, HDI tripolymer curing agent HX-90B, dehydrated n-butyl acetate and xylene are prepared to a component B; n-butyl acetate, propylene glycol methyl ether acetate, acetic ether, ethylene glycol diacetate and xylene are prepared to a thinner component C during constructing; the paint is prepared by mixing the components A, B and C according to the weight ratio of 1: 0.5: (0.5-0.8). By using the characteristics of high solid content and good flexibility of the raw materials such as the castor oil alkyd resin and HDI diisocyanate, the paint of the invention improves the flexibility and the shock resistance of painted films, enables coated layers to have good transparency, high fullness and excellent flexibility and shock resistance, and is specifically suitable for coating wood artware and cane furniture.

Owner:GUANGDONG BADESE CHEM

Hard alloy extrusion forming agent, preparation method thereof and application of hard alloy extrusion forming agent in extrusion production

The invention discloses a hard alloy extrusion forming agent, a preparation method thereof, and application of the hard alloy extrusion forming agent in extrusion production. The hard alloy extrusion forming agent comprises the following components in percentage by weight: 60 to 85 percent of a solvent namely ethylene glycol diacetate, 10 to 30 percent of a bonding agent namely ethyl cellulose and 5 to 10 percent of a surface active agent namely fatty alcohol-polyoxyethylene ether. The preparation method of the hard alloy extrusion forming agent comprises the steps of blending, mixing, heating and stirring materials. The application of the hard alloy extrusion forming agent in extrusion production of a hard alloy comprises the following steps of: blending materials, and performing ball milling on 0.8 to 3.0 weight percent of a plasticizer namely polyethylene glycol stearate and the balance of a hard alloy raw material; drying and granulating to obtain a mixture containing the plasticizer; mixing 5 to 7 weight percent of a forming agent with the mixture to obtain an extrusion feeding material; extruding a blank; drying to remove the solvent in the forming agent; curing the blank, and fixing the length of the blank through semi-finishing to form a semi-finished product; and sintering to obtain a finished product. By adopting the hard alloy extrusion forming agent, the qualified rate and labor efficiency of a product are improved, the cost is reduced, the localization, safety and environmental friendliness of raw materials are achieved, and the operating environment is improved.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

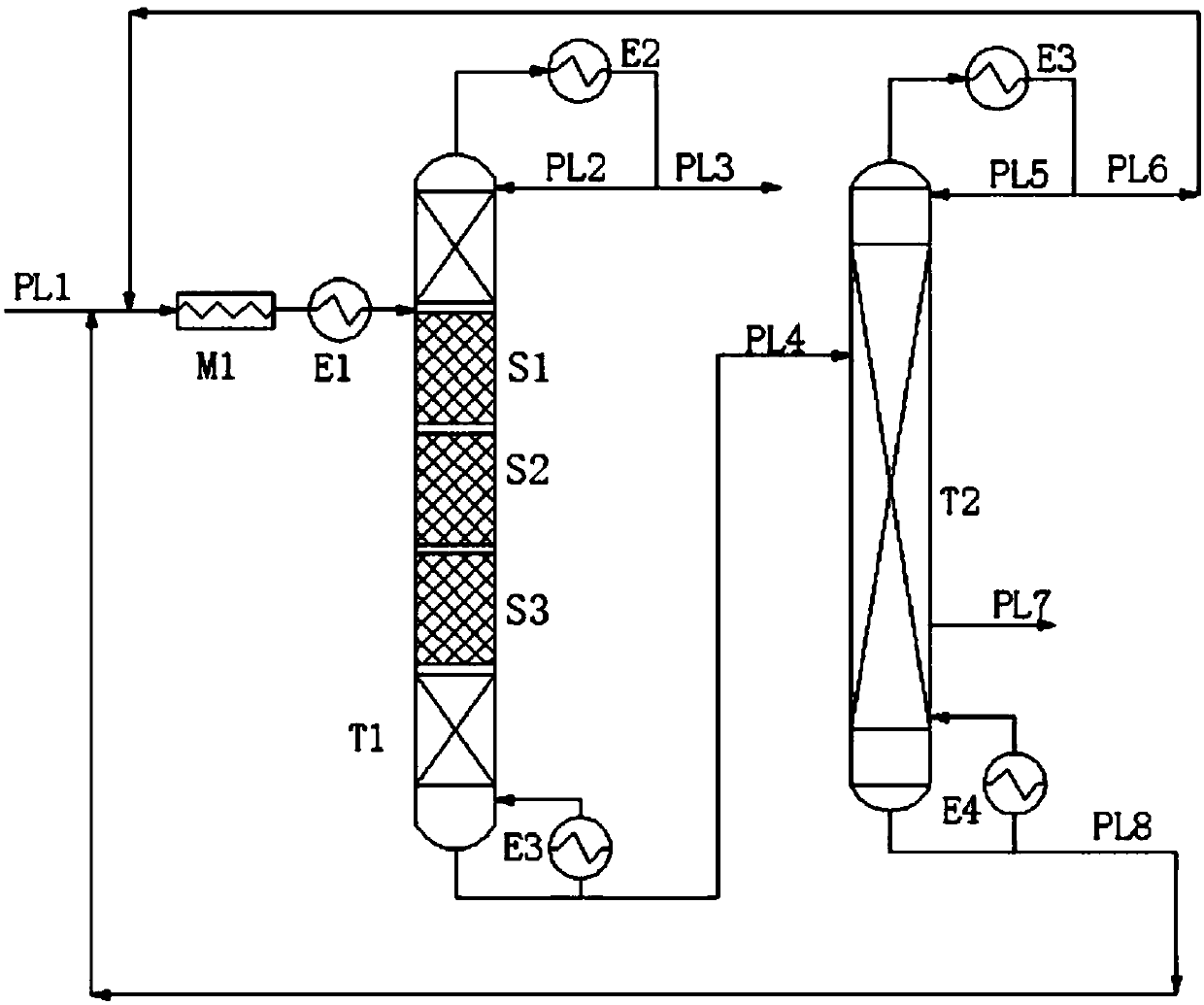

Method for preparing high-purity ethylene glycol diacetate through direct esterification

InactiveCN109369396ARealize industrial productionEmission reductionOrganic compound preparationChemical industryEthynodiol DiacetateContinuous reaction

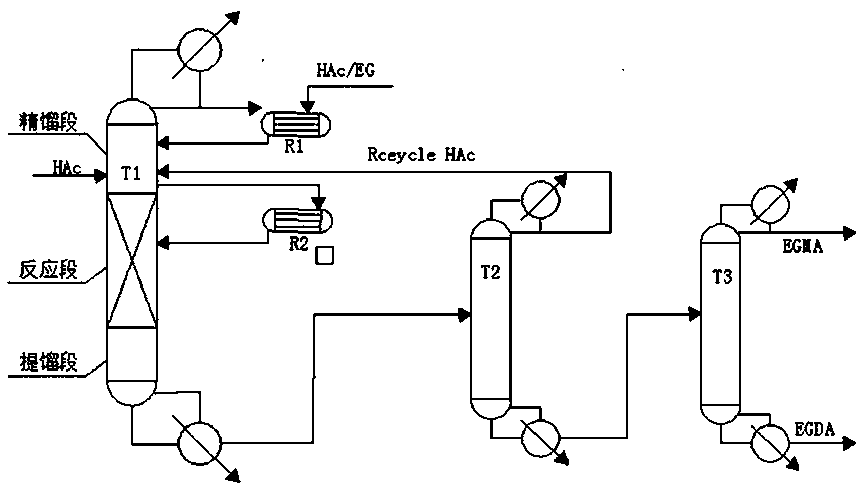

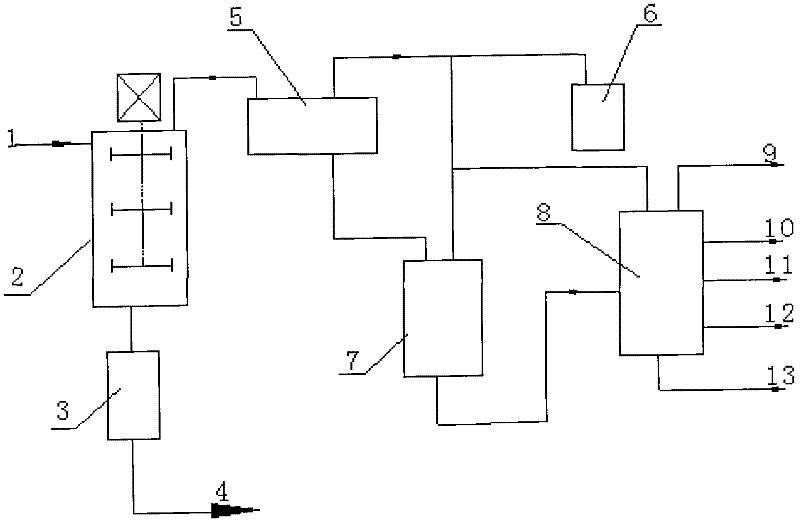

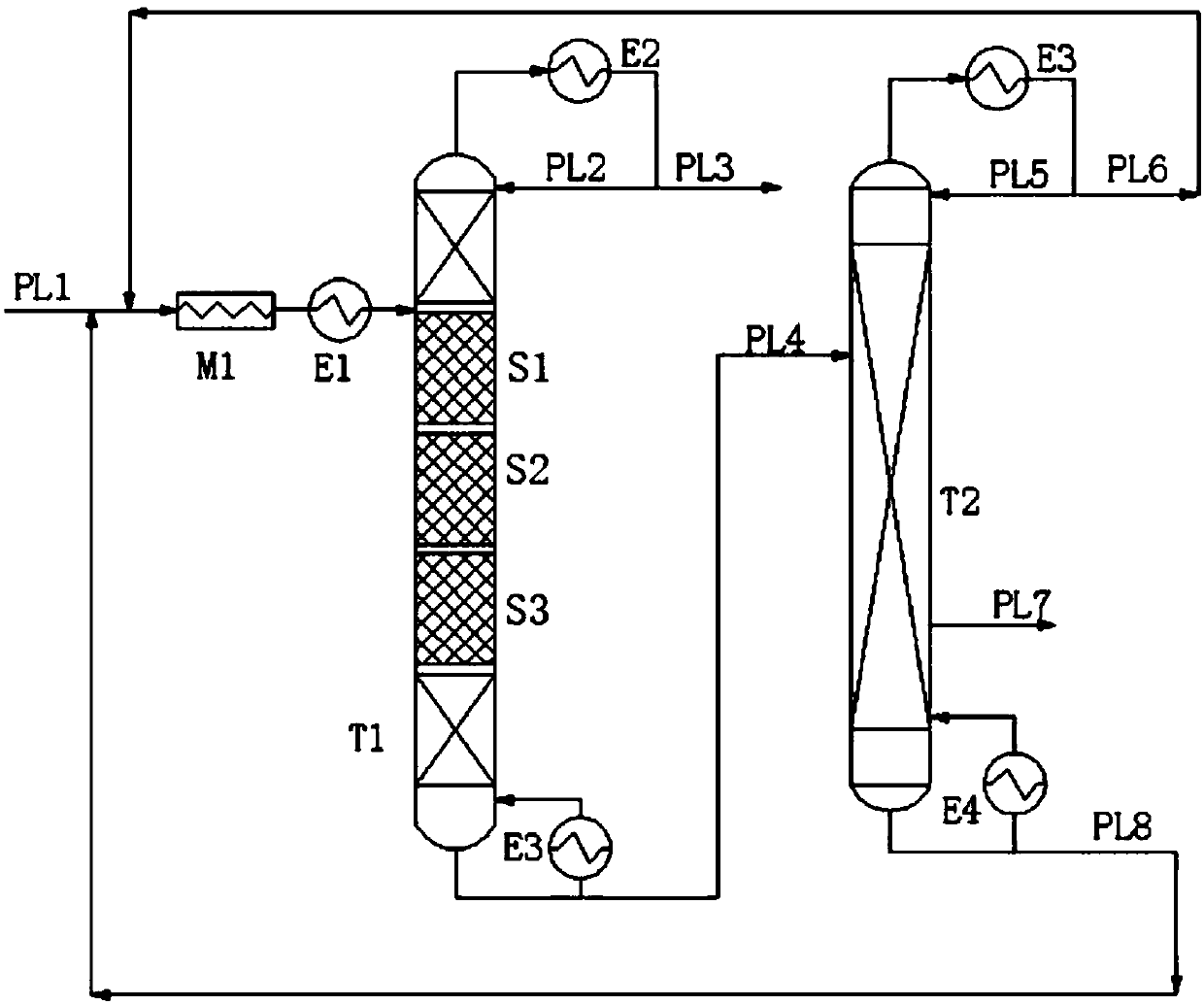

The invention discloses a method for preparing high-purity ethylene glycol diacetate through direct esterification. The ethylene glycol diacetate is synthesized from ethylene glycol and acetic acid ina catalytic rectifying tower which is composed of a backpack type reactor, a rectifying section, a reaction section and a stripping section. The acetic acid is fed byin two streams, one stream of theacetic acid is fed from the lower end of the rectifying section, the other stream of the acetic acid and the ethylene glycol are mixed and then enter the backpack type reactor, the reactor contains an acid catalyst, and the ethylene glycol and the acetic acid react in the reactor and then enter a reaction rectifying tower from the upper end of the reaction rectifying tower for continuous reaction. The reaction section in the catalytic rectifying tower is filled with catalytic padding, the ethylene glycol and the acetic acid react in a tower T1 to generate the ethylene glycol diacetate (EGDA),T2 is an acetic acid recovery tower, recovered acetic acid is circularly fed into the tower T1 as a raw material, T3 is a product refining tower, ethylene glycol monoacetate (EGMA) is discharged fromthe top of the tower T3, and high-purity EGDA is discharged from a tower kettle. The method has the advantages of being high in reaction conversion rate, low in energy consumption, high in raw material utilization rate and the like.

Owner:FUZHOU UNIV

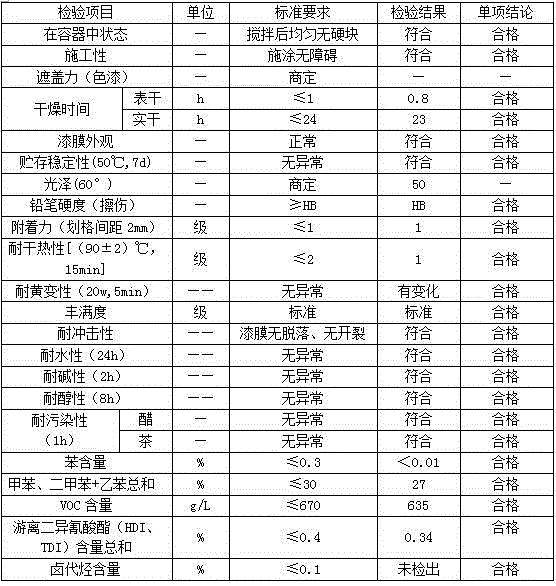

Environment-friendly curtaining odor-removing PU matted varnish and preparation method thereof

InactiveCN106349920AUniform transparencyUniform flatnessPolyurea/polyurethane coatingsCyclohexanoneFatty acid

The invention relates to an environment-friendly curtaining odor-removing PU matted varnish and a preparation method of the environment-friendly curtaining odor-removing PU matted varnish, and belongs to the technical field of wooden coating manufacturing. The environment-friendly curtaining odor-removing PU matted varnish is prepared by mixing component A, component B, and component C according to the weight ratio of 1: 0.5: 0.4-0.7; the component A is composed of fatty acid modified odor removal alkyd resin, short-oil castor oil alkyd resin, polyamide wax anti-sediment, wetting dispersant, flatting agent, antifoaming agent, modified polyethylene wax powder, matt powder, propylene glycol monomethyl ether acetate, cyclohexanone, ethylene glycol diacetate, 50% by mass of nitrocotton fluid, and n-butyl acetate; the component B is composed of aliphatic series polyisocyanate, TDI tripolymer curing agent, TDI prepolymer, and n-butyl acetate; the component C is composed of xylene, n-butyl acetate, propylene glycol monomethyl ether acetate, acetate, and ethylene glycol diacetate. The coating has strong adhesive force, good transparency, high fullness, good flexibility, good scratching resistance, uniform gloss, stability and impact-resistance, and good waterproof and chemical resistance.

Owner:山东巴德士新材料有限公司

Preparation method of ethylene glycol monoacetate and ethylene glycol diacetate

ActiveCN103183609ALow priceIncrease valuePreparation by ester-hydroxy reactionBulk chemical productionChemical reactionSynthesis methods

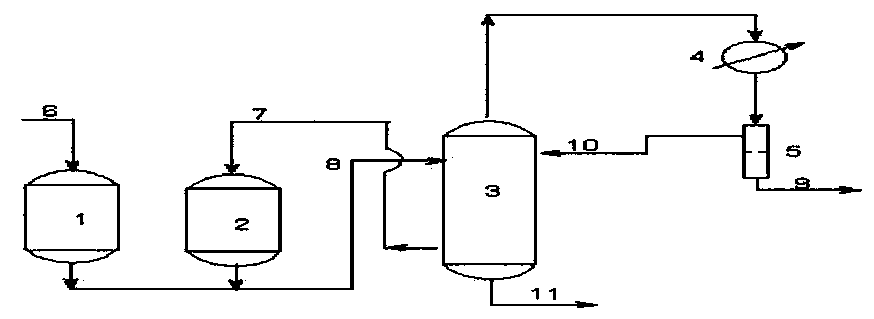

The invention discloses a preparation method of ethylene glycol monoacetate and ethylene glycol diacetate. The preparation method is to take sec-butyl acetate and ethylene glycol as raw materials, perform transesterification in the presence of a base catalyst to prepare ethylene glycol monoacetate and ethylene glycol diacetate, and comprises the specific steps of primary transesterification, chemical reaction equilibrium breaking of transesterification, final-phase transesterification, separation and purification of the products ethylene glycol monoacetate and ethylene glycol diacetate, and the like. The preparation method of ethylene glycol monoacetate and ethylene glycol diacetate is high in product yield, quick in reaction speed, low in power consumption, easy to separate and purify the products, low in cost and simple in technique. In addition, the synthesis method provided by the invention can prepare an important common solvent sec-butyl alcohol. The products are all required by application, so that the utilization ratio of the products is high, the three wastes are less, and the preparation method is green and environment-friendly.

Owner:深圳市飞扬特化新材料有限公司

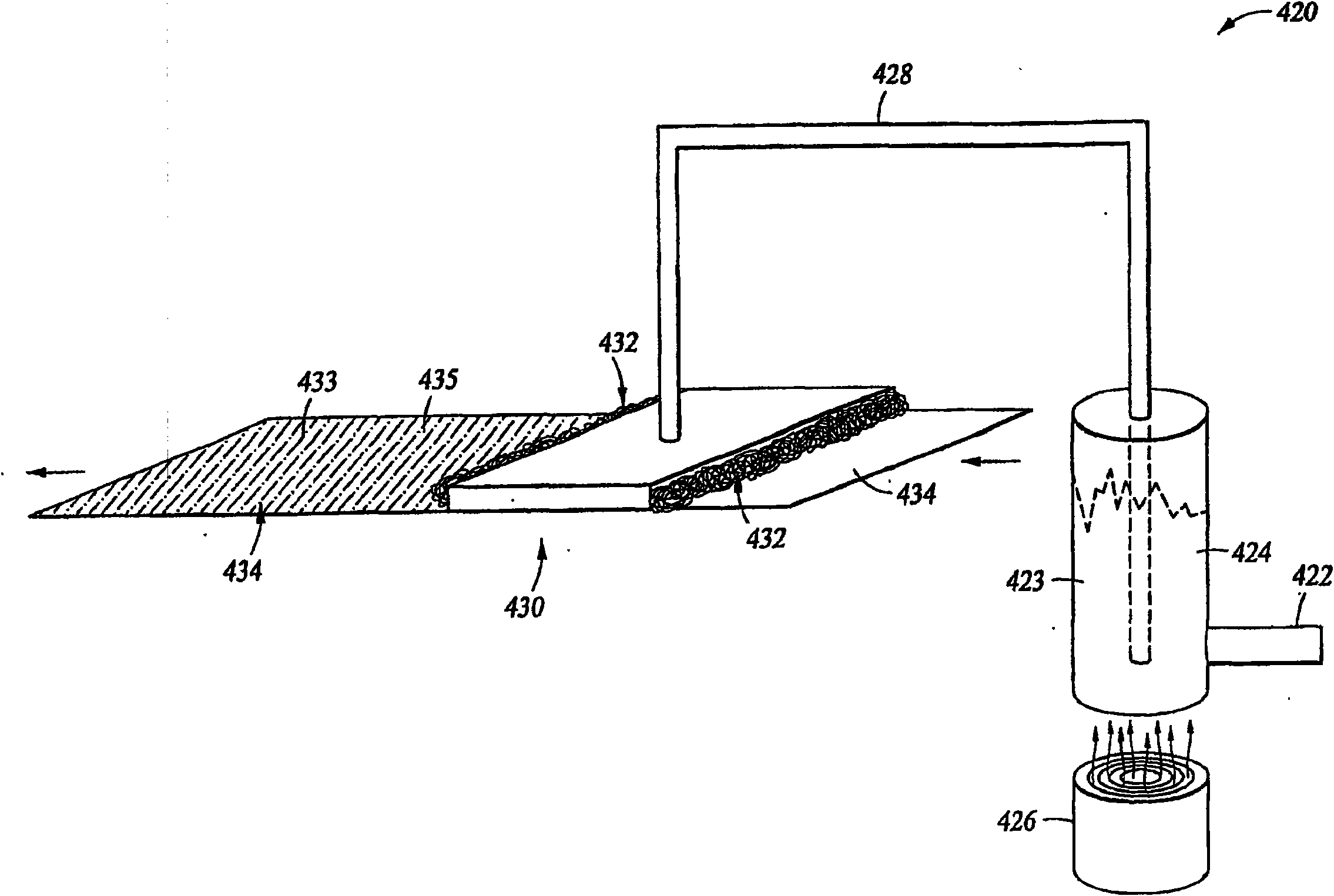

Stripping and removal of organic-containing materials from electronic device substrate surfaces

InactiveUS7402213B2Avoid and minimize reactivityEasily cleaned off substrate surfacePhotomechanical apparatusCleaning using liquidsAcetic anhydrideEthynodiol Diacetate

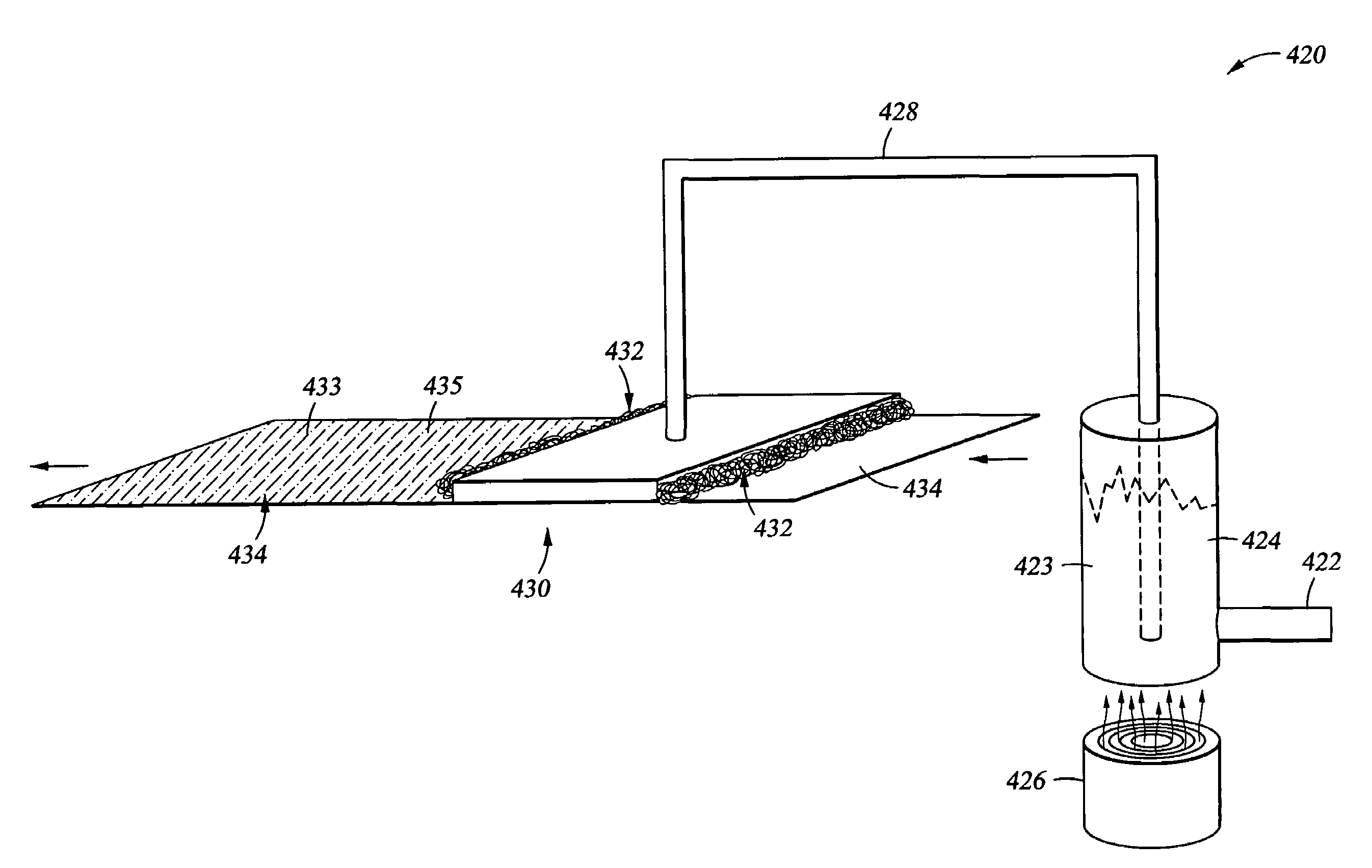

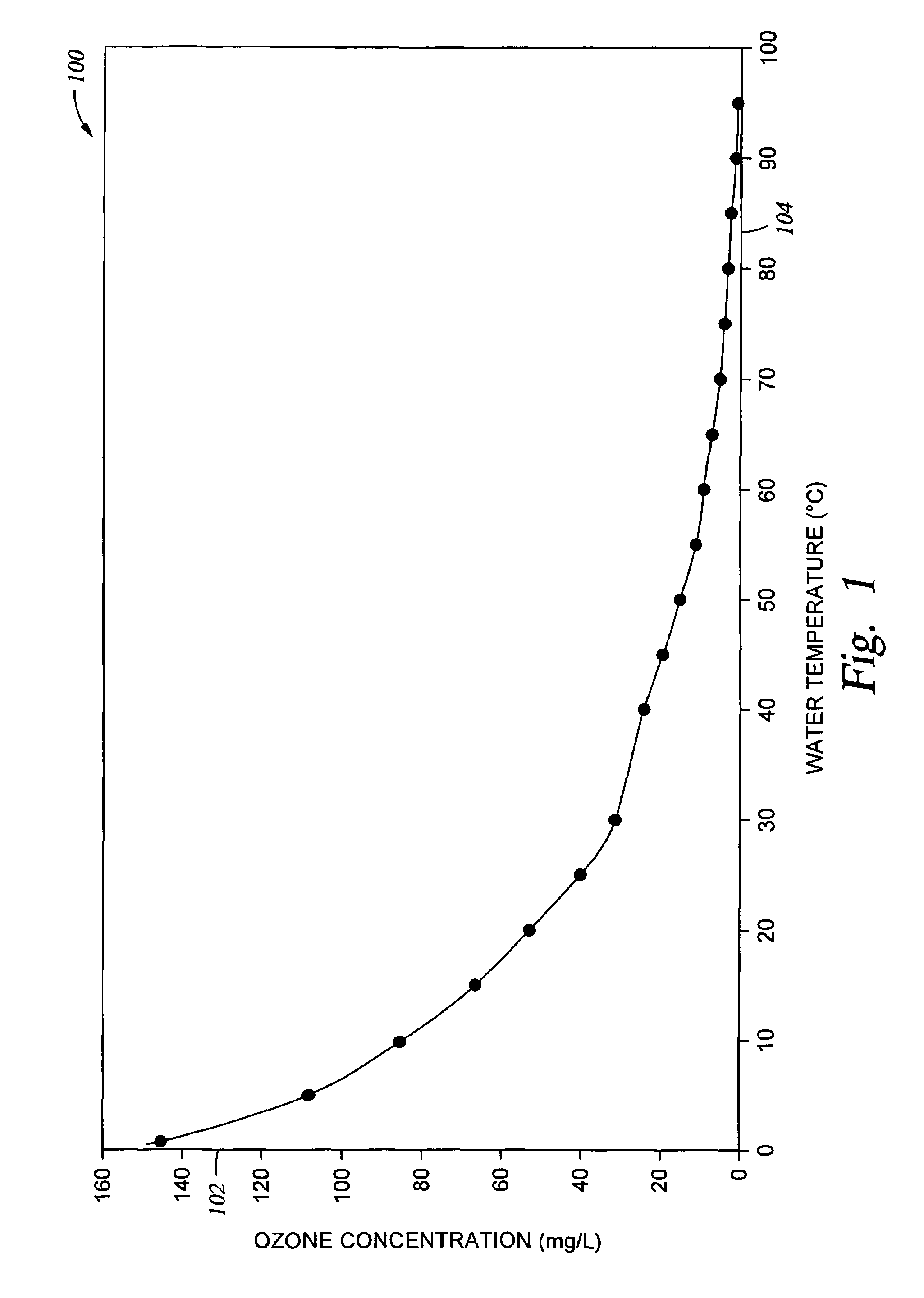

Described herein is a method of removing an organic-containing material from an exposed surface of a large substrate (at least 0.25 m2). The substrate may comprise an electronic device. The exposed surface is treated with a stripping solution comprising ozone (O3) in a solvent, where the solvent comprises acetic anhydride. The stripping solvent used to form the stripping solution may comprise a mixture of acetic anhydride with a co-solvent selected from the group consisting of a carbonate containing 2-4 carbon atoms, ethylene glycol diacetate, and combinations thereof. In some instances, the stripping solution may contain only acetic anhydride and ozone, where the ozone concentration is typically about 300 ppm or greater.

Owner:APPLIED MATERIALS INC

Vinyl acetate production process

InactiveUS8399700B2Improve processing yieldOrganic compound preparationPreparation by ester-hydroxy reactionGas phaseOxygen

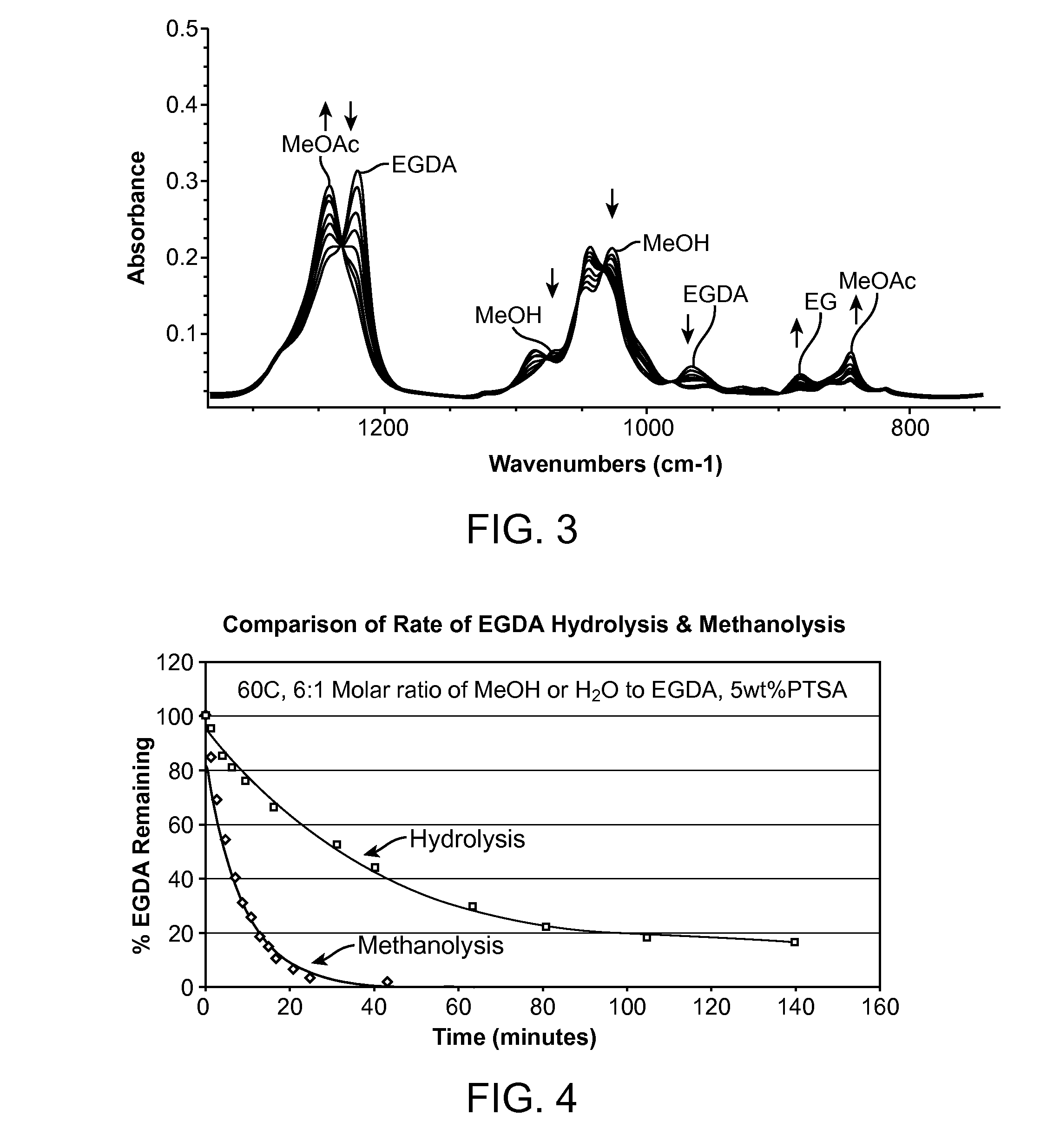

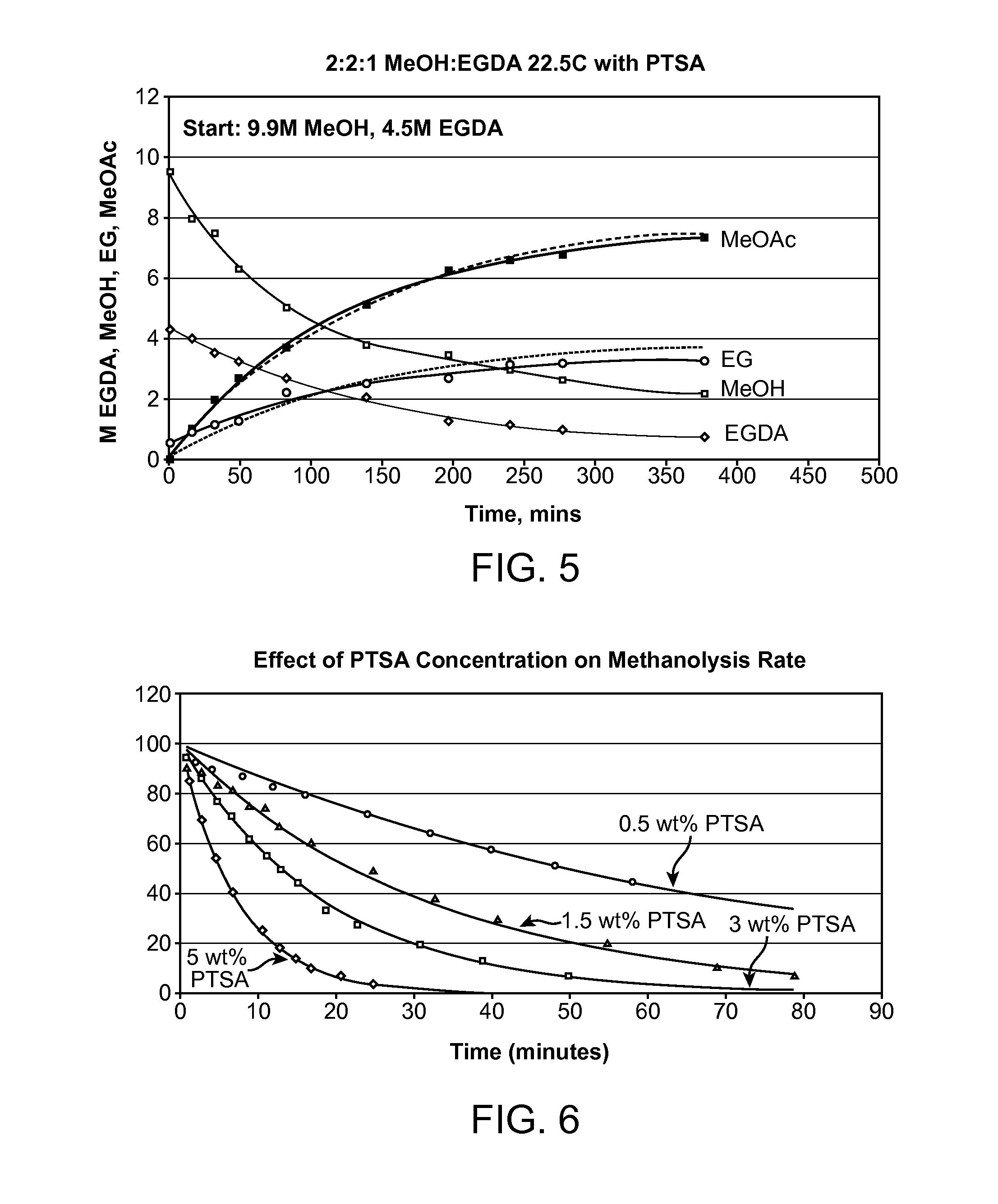

A process is disclosed for the production of vinyl acetate where a mixture of ethylene, acetic acid, and oxygen is reacted in the presence of a catalyst to produce a product mixture of vinyl acetate, ethylene, carbon dioxide, acetic acid, water, ethyl acetate, and ethylene glycol diacetate. The product mixture contains both a gaseous phase and a liquid phase, which are separated. The gas phase contains at least carbon dioxide, which is removed via gas stream. The crude vinyl acetate stream is removed via a liquid stream. The crude vinyl acetate is then further separated to isolate a stream containing at the majority of the ethylene glycol diacetate. The ethylene glycol diacetate stream is then methanolyzed in the presence of a methanolyzing catalyst, to recover methyl acetate, which can be optionally recycled as a feed stock to an acetic acid plant.

Owner:LYONDELLBASELL ACETYLS

Method for synthesizing ethylene glycol diacetate by adopting transesterification method

InactiveCN104355996AHigh yieldImprove conversion ratePreparation by ester-hydroxy reactionChemical industryTransesterificationReactive distillation

The invention relates to a method for synthesizing ethylene glycol diacetate by adopting a reactive distillation technology. Sec-butyl acetate and ethylene glycol are used as raw materials, ethylene glycol diacetate is produced by transesterification on the presence of a basic catalyst, and a byproduct is ethylene glycol monoethyl acetate. According to the method, the yield of the ethylene glycol diacetate can reach over 90 percent, and the method has the advantages of high conversion rate, mild reaction conditions, high yield, no corrosion, no environmental pollution and the like.

Owner:天津中昊天久工程技术有限公司

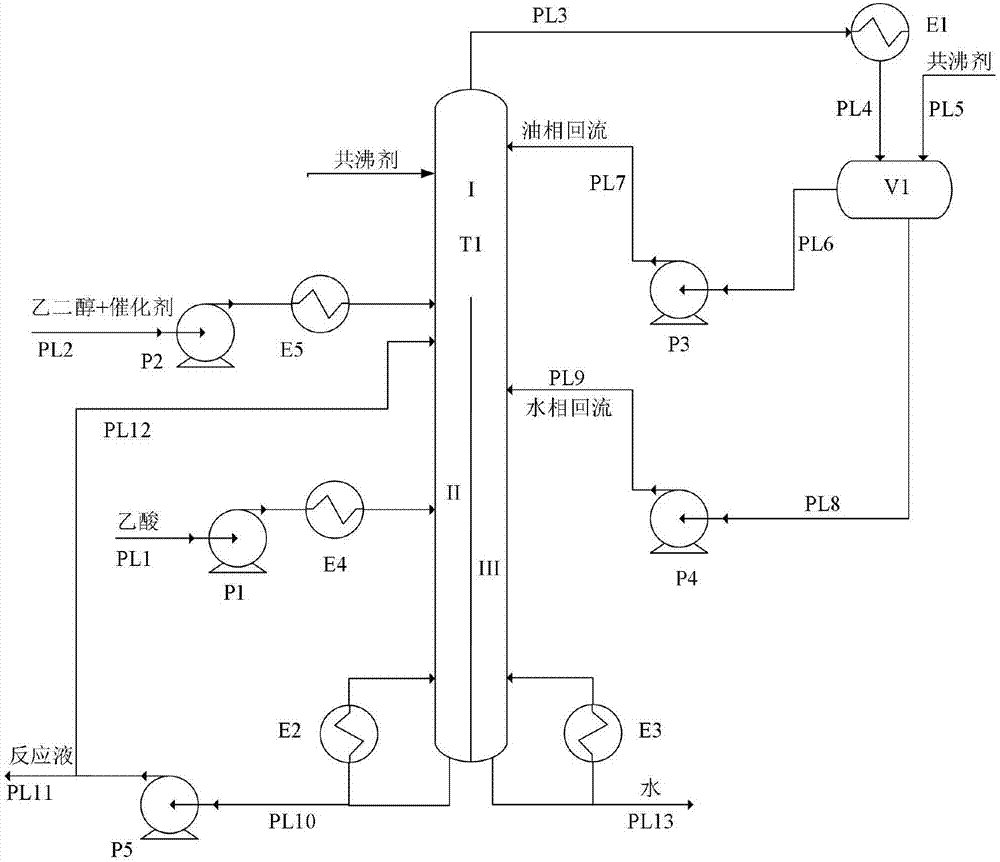

Device and method for producing ethylene glycol diacetate by adopting dividing-wall reaction rectifying column

PendingCN107501093ALess investmentImprove conversion rateOrganic compound preparationChemical industryReboilerOil phase

The invention relates to a device and a method for producing ethylene glycol diacetate by adopting a dividing-wall reaction rectifying column. The device comprises a dividing-wall reaction rectifying column, a condenser, an acetic acid preheater, an ethylene glycol preheater, a layering device, a main column reboiler, an auxiliary column reboiler, a raw material acetic acid feeding pump, a raw material ethylene glycol and catalyst feeding pump, an oil phase reflux pump, a water phase feeding pump and a main column kettle fluid circulating pump; the ethylene glycol diacetate is produced by virtue of esterification reaction of ethylene glycol and acetic acid which are adopted as raw materials, and water generated in the esterification reaction is separated in the dividing-wall reaction rectifying column directly by virtue of co-boiling rectification, so that the water generated in the reaction is removed out of a reaction system in time, and the reactant acetic acid can be prevented from being removed out of the reaction system along with the water. The esterification, dehydration of acetic acid and recycling of entrainer are integrally performed in one column, so that not only can the reactant conversion rate and product yield be increased, but also the integration of the esterification and dehydration of acetic acid in the same column is realized, and the energy consumption and equipment investment can be effectively reduced.

Owner:FUQING BRANCH OF FUJIAN NORMAL UNIV

Starch-based modified composite material for 3D printing

Owner:SUZHOU BC TECH

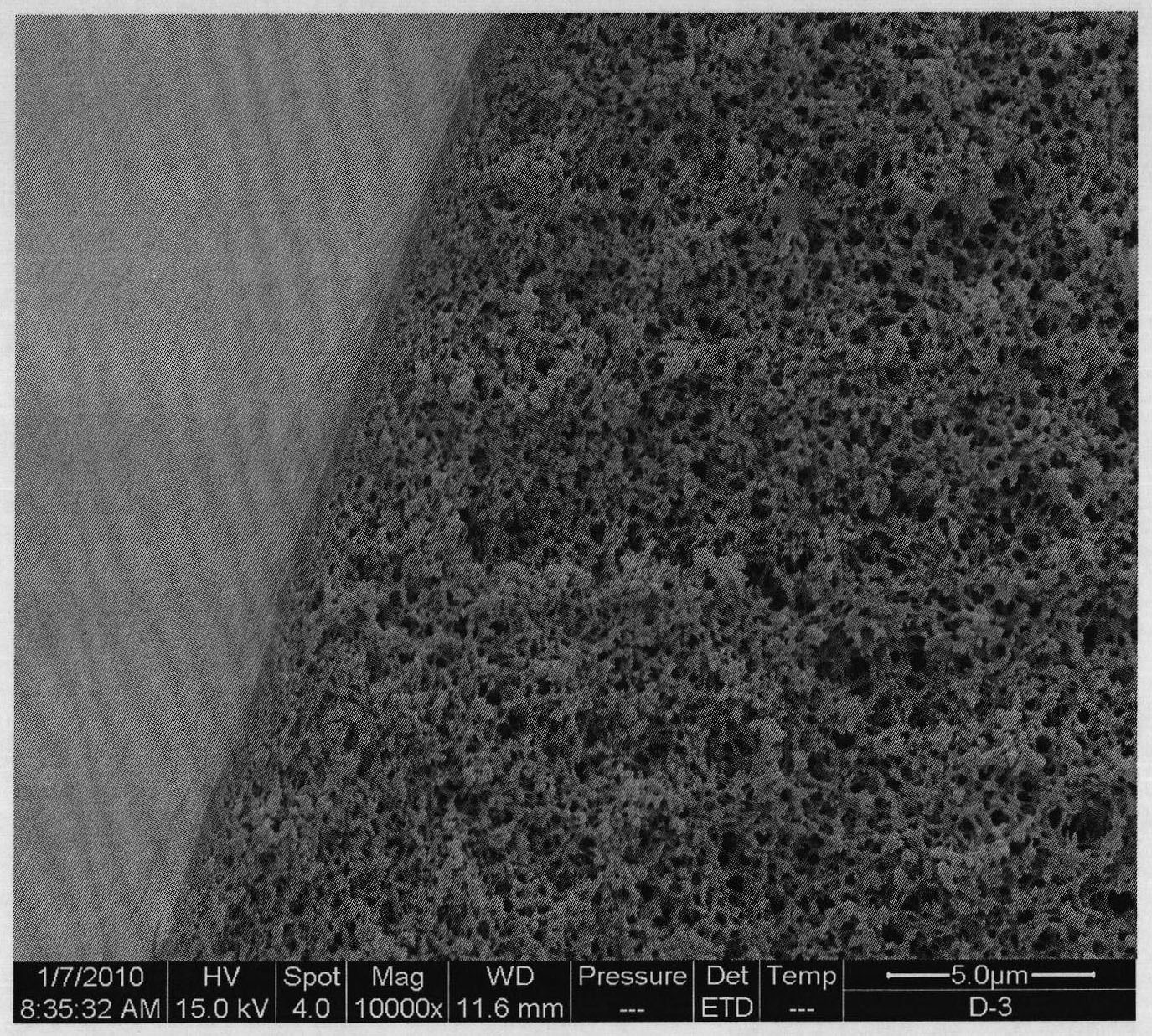

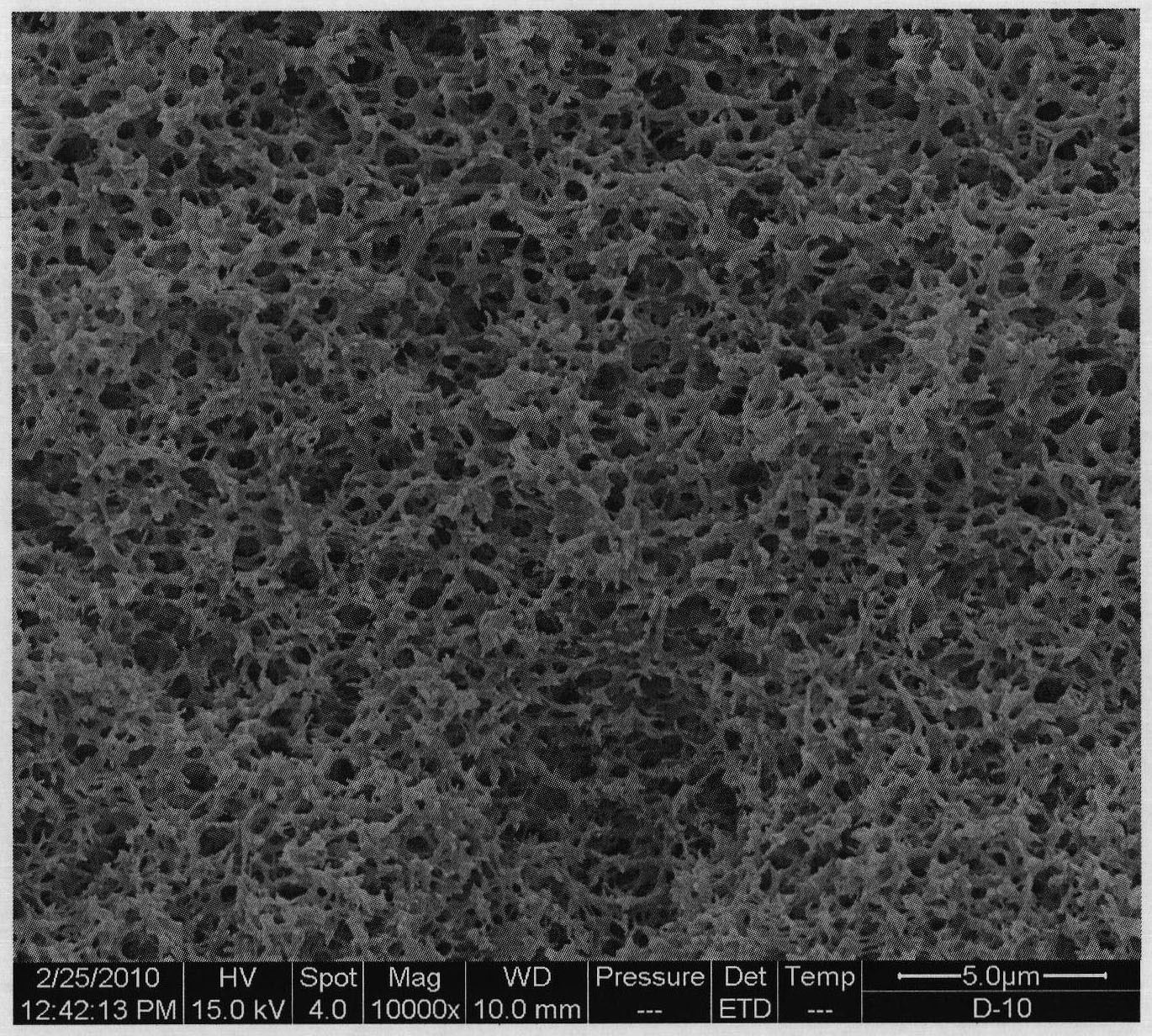

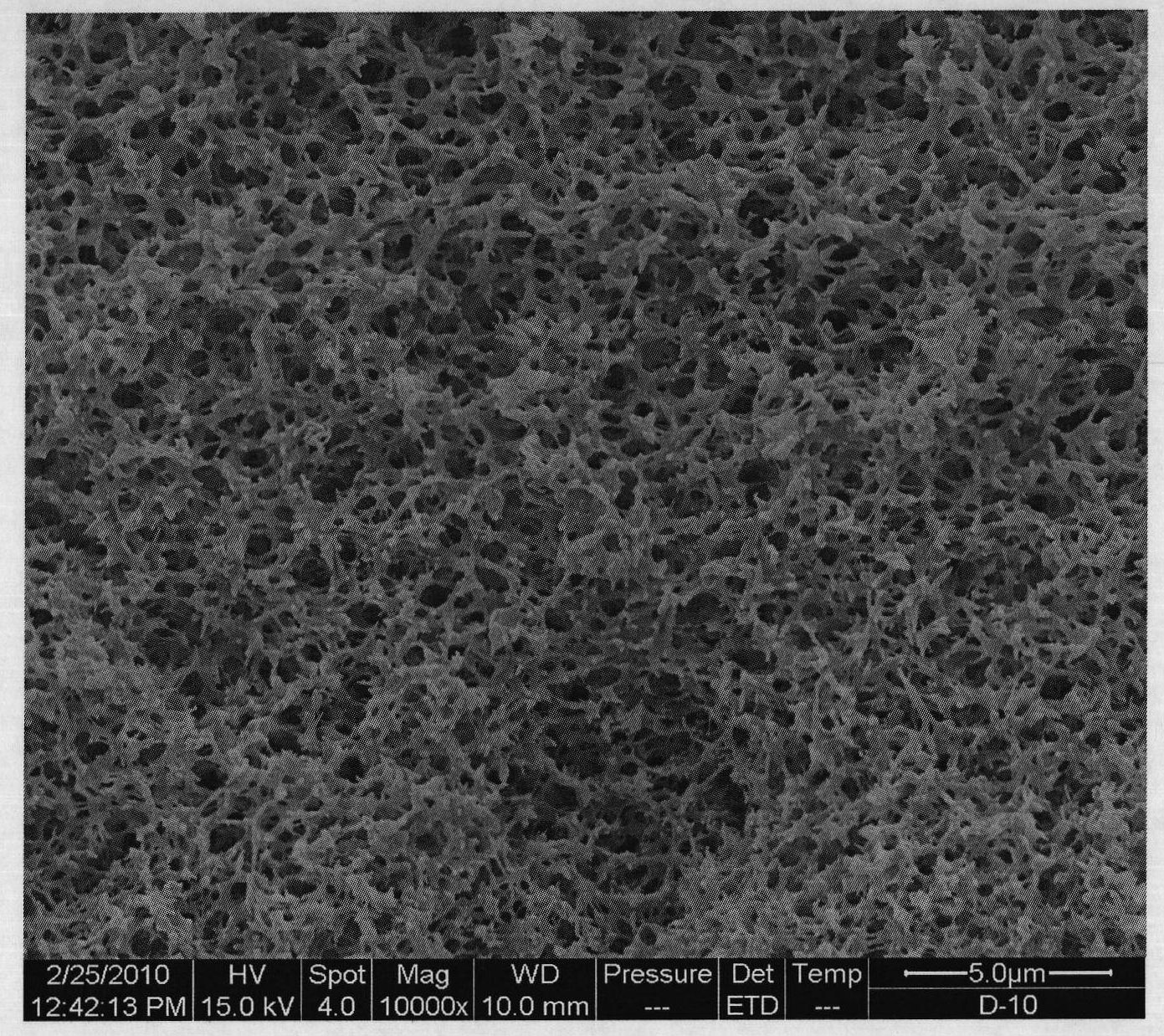

Hollow-fiber membrane with density gradient pores and preparation method

The invention relates to a polyvinylidene fluoride porous hollow-fiber membrane and a preparation method thereof. The membrane is prepared from the following formula ingredients in percentage by mass: 25 to 45 percent of polyvinylidene fluoride (PVDF) serving as a first polymer P1, 0 to 3 percent of polyvinylpyrrolidone (PVP) serving as a second polymer P2, 32 to 45 percent of ethylene acetate serving as a first diluting agent D1 and 15 to 36 percent of 1,3-propanediol serving as a second diluting agent D2. The PVDF hollow-fiber ultrafiltration and microfiltration membranes prepared by the method have the advantages of superior chemical stability, pollution resistance and high strength and can provide a high-performance membrane product for the MBR process.

Owner:苏州膜华材料科技有限公司

Water-soluble sticking cloth resin cleaning agent and preparation method thereof

InactiveCN106635508AGood removal effectLow toxicityOrganic non-surface-active detergent compositionsNon-surface-active detergent solventsSolubilityTextile printer

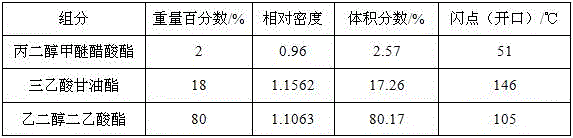

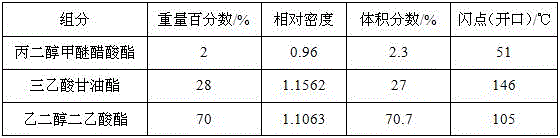

The invention discloses a water-soluble sticking cloth resin cleaning agent and a preparation method thereof. The water-soluble cleaning agent which is used for cleaning a guiding belt table adhesive of a textile printing machine is obtained by mixing 1%-5% of propylene glycol methyl ether acetate, 10%-30% of glyceryl triacetate and 50%-80% of ethylene glycol diacetate according to a formula and filtering. The water-soluble sticking cloth resin cleaning agent prepared by the invention has good water solubility and is an organic mixed solvent with a high flashing point and a high ignition point; and the water-soluble sticking cloth resin cleaning agent has no corrosion on a printing guiding belt, has an obvious effect of removing the table adhesive, and has the characteristics of low toxicity, environmental protection, high stability and the like.

Owner:SHANDONG HUANGHE DELTA INST OF TEXTILE SCI & TECH RES INST

Recycling and separating process of heavy component residual liquid in carbonylation production process of acetic acid

ActiveCN102126943AEfficient recyclingSimple processOrganic compound preparationCarboxylic acid esters preparationAcetic acidEthynodiol Diacetate

The invention discloses a recycling and separating process of heavy component residual liquid in the carbonylation production process of acetic acid, belonging to the separation technical field of the organic chemical engineering. The process comprises the following steps: firstly, the residual liquid is sent to a wiped film evaporator to perform reduced pressure operation and remove high polymer heavy component; and secondly, light component enters a batch distillation device to obtain the products such as acetic acid, acetoxyacetic acid and ethylene glycol diacetate through separation and purification. The invention adopts the recycling and separating process of the acetic acid heavy component residual liquid; the flow is simple, the process is easy to operate; after the high polymer heavy component is removed, the residual liquid meets the requirements of environmental protection treatment; and the products with high added value can be effectively recycled, the recovery rate is more than 90% and the process is an efficient and environmentally friendly recycling and separating process.

Owner:NANJING CHANGJIANG JIANGYU PETROCHEM CO LTD

Reactive distillation process for heavy component residue liquid produced in process of producing acetic acid through carbonylation

ActiveCN105237399AReduce energy consumptionEfficient use ofOxygen-containing compound preparationOrganic compound preparationGas phaseReboiler

The invention provides a reactive distillation process for heavy component residue liquid produced in process of producing acetic acid through carbonylation. The reactive distillation process comprises the following steps that 1, the content of acetic acid, ethylene glycol diacetate and acetoxyacetic acid of the heavy component residue liquid is sampled and analyzed, and the content for complete acetic acid conversion is worked out; 2, heavy component residue liquid, methyl alcohol and sulfuric acid are added into a heavy component rectifying tower storage tank; 3, a heavy component reboiler heats a heavy component rectifying tower kettle through a control valve, gas-liquid mass transfer is carried out on the gas phase and the liquid phase in the heated materials, gas phase materials are condensed through a condenser and then pass through a reflux ratio controller, one part of the materials achieve reflux, the content of methyl acetate in the top of a sampling analysis tower is in a qualified range, one part of qualified products enter an ester receiving tank, a transition distillate tank and an acetoxyl group acetic acid buffer tank, and heating is stopped when no material exists on the tower top for extraction. The recycle separation method is low in energy consumption and high in acetic acid yield, and a small quantity of solid waste residues are obtained after rectification treatment.

Owner:南京长江江宇环保科技股份有限公司

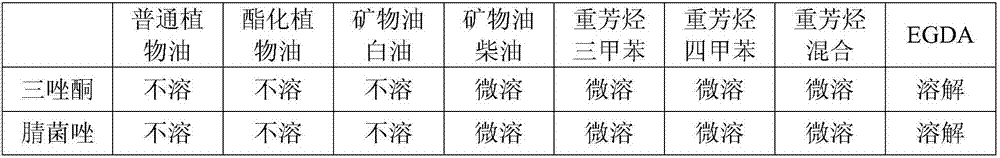

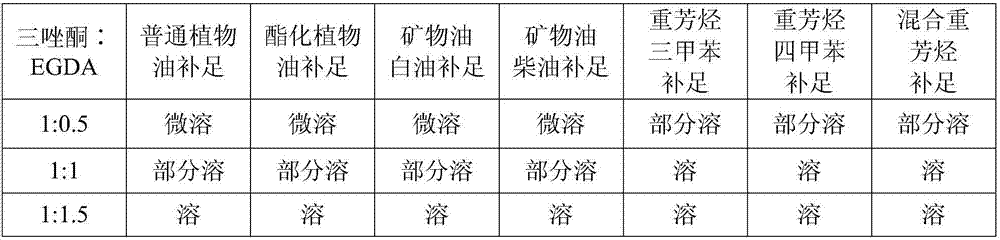

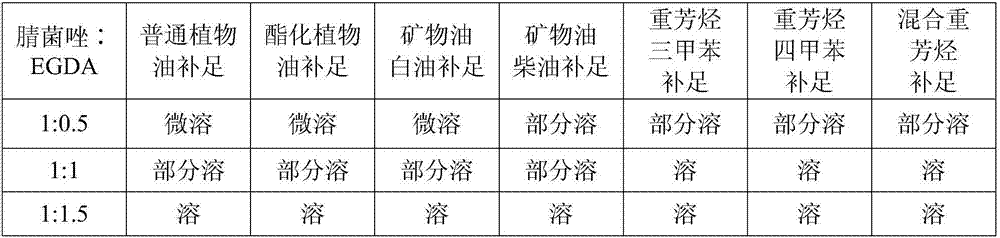

Transparent liquid preparation of pesticide and preparation method for transparent liquid preparation

The invention discloses a transparent liquid preparation of a pesticide. The transparent liquid preparation is prepared from 1 to 30 percent of a component A, 2 to 70 percent of a component B and the balance of another component and / or an excipient, wherein the component A is myclobutanil and / or triadimefon, and the component B is ethylene glycol diacetate. The transparent liquid preparation is missible oil, oil, an oil spray, a hot fogging concentrate, a smoke agent, ultralow-volume liquid, a soluble concentrate or microemulsion. The transparent liquid preparation provided by the invention can be used for preventing and controlling diseases of field food crops such as wheat, rice and corns and crops such as fruit trees, vegetables and cotton as a normal-volume, low-volume and ultra-volume spray.

Owner:SHENZHEN NOPOSION AGROCHEM

Method for preparing ethylene glycol diacetate and sec-butanol and catalyst system and device used in method

ActiveCN109956849AEasy to separateIncrease reaction rateMolecular sieve catalystsPreparation by ester-hydroxy reactionSec-ButanolEthynodiol Diacetate

The invention relates to a method for preparing ethylene glycol diacetate and sec-butanol and a catalyst system and device used in the method. The method comprises the following steps: sec-butyl acetate and ethylene glycol are used as raw materials, in a reactor filled with a metal wire mesh filler having the surface coated with a ZSM-5 molecular sieve membrane, a reaction is carried out under thecatalytic action of a composite catalytic system sodium ethylene glycol / N-acetylpyrrolidone, and the ethylene glycol diacetate product is separated from the reaction products. According to the methodprovided by the invention, the conversion rate of the ethylene glycol is 100%, the yield of the ethylene glycol diacetate can be up to 99.5% or more, the yield of the sec-butanol is 100%, and the method has the advantages of a high conversion rate, a high yield, less side reactions, good product quality, simple separation and the like.

Owner:HUNAN ZHONGCHUANG CHEM

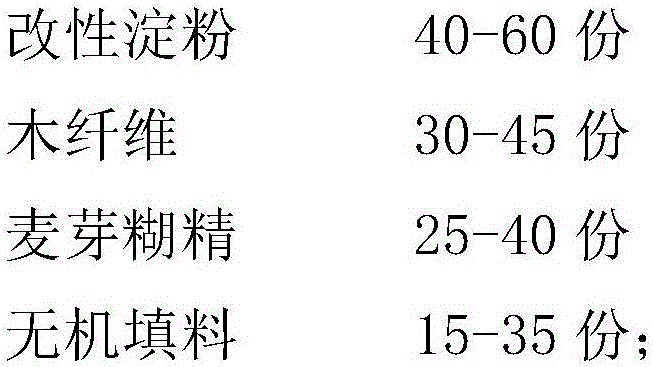

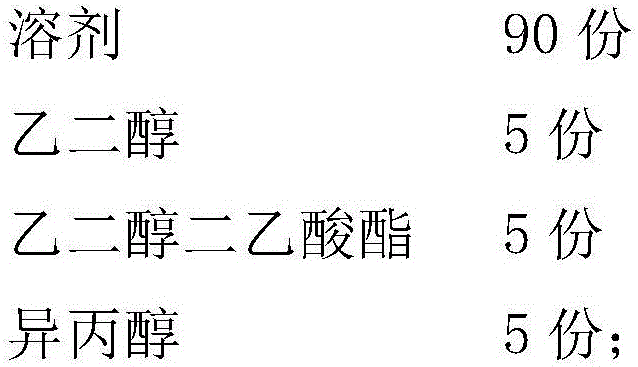

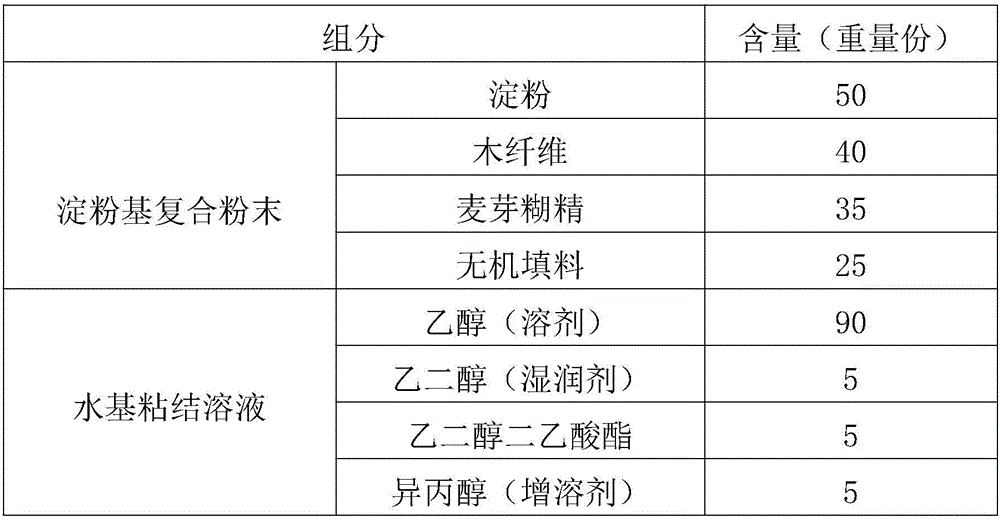

Three-dimensional rapid formed composite powder material

InactiveCN106243397AImprove liquidityImprove smoothnessAdditive manufacturing apparatusCelluloseWater based

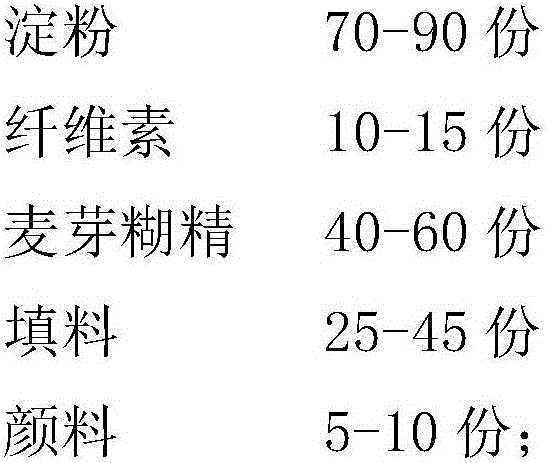

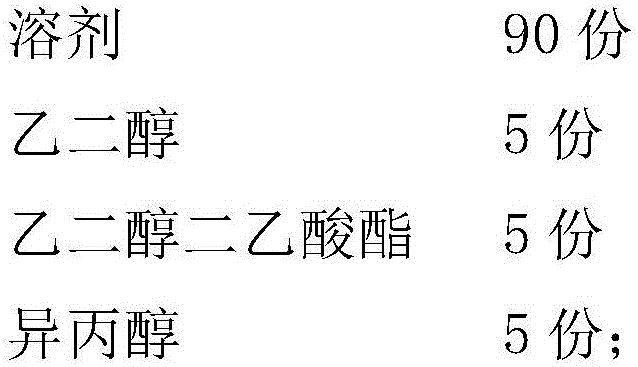

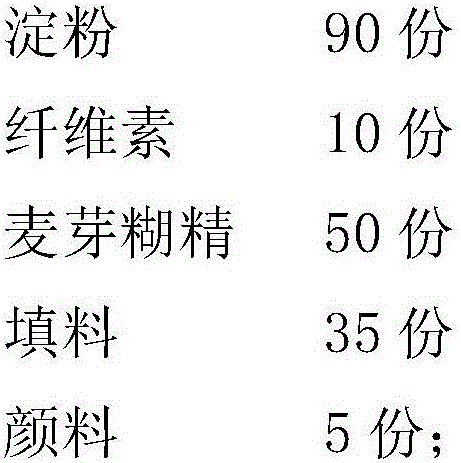

The invention discloses a three-dimensional rapid formed composite powder material. The composite powder material comprises: starch-based composite powder comprising, by weight, 70-90 parts of starch, 10-15 parts of cellulose, 40-60 parts of maltodextrin, 25-45 parts of a filler and 5-10 parts of a pigment; and a water-based binding solution comprising, by weight, 90 parts of a solvent, 5 parts of ethylene glycol, 5 parts of ethylene glycol diacetate and 5 parts of isopropanol, wherein the particle size of the starch is 1-10 [mu]m, the particle size of the cellulose is 50-100 [mu]m, the particle size of the maltodextrin is 100-300 [mu]m, and the granularity of the starch-based composite powder is 200-400 meshes. Adjustment of the formula of the material and use of the water-based binding solution make the integral composite material be easy to bind and improve the forming speed, and the composite powder material which is based on the starch-based composite powder is degradable, and is an environmentally-friendly material.

Owner:SUZHOU BC TECH

Stripping and removal of organic-containing materials from electronic device substrate surfaces

InactiveCN101815586AReduce solubilitySmall smellDetergent mixture composition preparationPhotomechanical apparatusAcetic anhydrideEthynodiol Diacetate

Described herein is a method of removing an organic-containing material from an exposed surface of a large substrate (at least 0.25 m2). The substrate may comprise an electronic device. The exposed surface is treated with a stripping solution comprising ozone (O3) in a solvent, where the solvent comprises acetic anhydride. The stripping solvent used to form the stripping solution may comprise a mixture of acetic anhydride with a co-solvent selected from the group consisting of a carbonate containing 2 - 4 carbon atoms, ethylene glycol diacetate, and combinations thereof. In some instances, the stripping solution, may contain only acetic anhydride and ozone, where the ozone concentration is typically about 300 ppm or greater.

Owner:APPLIED MATERIALS INC

Water glass slurry for grouting on mine working surface

InactiveCN101654614ASimple recipeGood process controllabilityDrilling compositionPorositySimple component

The invention provides water glass slurry for grouting on a mine working surface, wherein, the slurry takes ethylene acetate as a curing agent and water glass as a main agent; and 100 parts of slurrycomprises the following components by volume ratio: 15-60 parts of the water glass 38 Be, 1-10 parts of the ethylene acetate and water. In the invention, the water-soluble ethylene acetate is taken asthe curing agent; and the obtained grouting material has the advantages of low viscosity, high permeability, adjustable gelling time, simple components, non-corrosiveness and the like. The water glass slurry can be applied to the fields such as anti-seepage for hydraulic engineering, water plugging for a mine and the like, and the slurry especially has good application prospect on water blockingwith grout for the working surface of an underground microfracture stratum and a porosity stratum.

Owner:BEIJING CHINA COAL MINE ENG CO LTD

Production method of ethylene glycol diacetate (EGDA)

InactiveCN103435481AHigh activitySolution to short lifeOrganic compound preparationCarboxylic acid esters preparationChemical synthesisIon-exchange resin

The invention provides a production method of ethylene glycol diacetate (EGDA) and relates to a chemical synthesis technology. The production method of the EGDA comprises the following steps: in presence of a catalyst, carrying out an esterification reaction by taking ethylene glycol monomethyl ether and acetic acid as raw materials, and rectifying the obtained EGDA crude product to obtain an EGDA fine product, wherein the catalyst is metal-ion-modified styrene-divinyl benzene benzenesulfonic acid type acidic cation exchange resin with composite enhanced type macropores, the cation exchange resin is made by polymerizing styrene and divinyl benzene monomers and sulfonating on a benzene ring, and the metal ion is any one of Zn<2+>, Fe<3+>, Al<3+>, Na<+>, Fe<2+> or K<+>. By adopting the production method of the EGDA, the EGDA can be continuously produced, an operating mode is simple, raw material space velocity is high, production efficiency of the EGDA can be obviously improved, production cost of the EGDA can be reduced, and discharge of solid pollutants and waste water can be reduced; a reaction product does not need to be neutralized by adopting massive alkali, and service life of the catalyst is long.

Owner:JIANGSU HUALUN CHEM

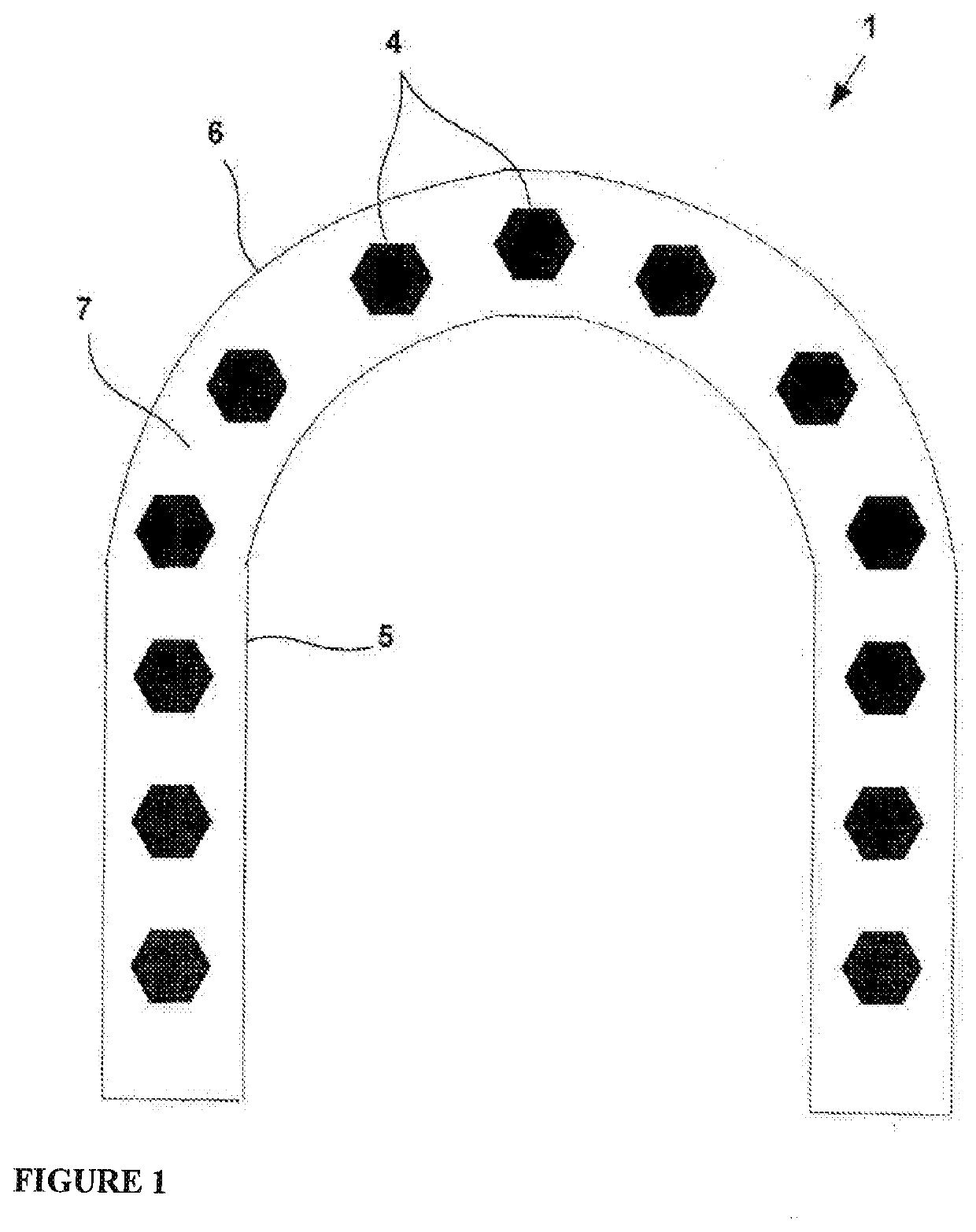

Hard Capsule Shell Compositions for the Oral Contraceptive Formulations

InactiveUS20190343770A1Organic active ingredientsInorganic non-active ingredientsDrospirenoneDietary supplement

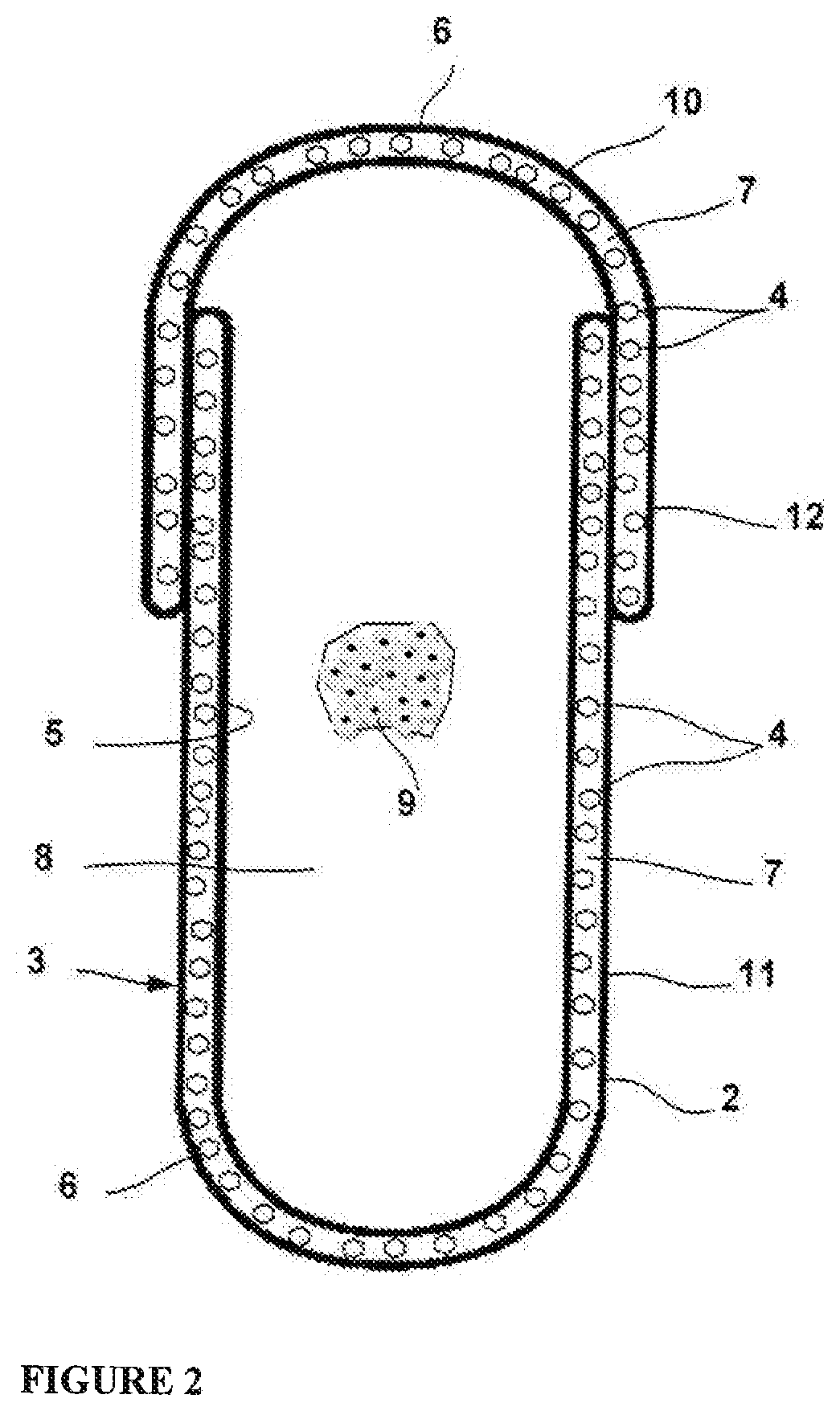

A hard shell capsule includes a body and a cap cooperatively defining a hollow core hard shell capsule. Each of the body and the cap has a composition that includes a polymer forming a hard polymer structure of the body and of the cap and comprises a drug. The body further comprises a therapeutically effective amount of drug A loaded throughout the composition; the cap further comprises a composition comprising a therapeutically effective amount of drug B loaded throughout the composition. The body and cap compositions together containing a therapeutically effective amount of the drugs A and B; said drugs being oral contraceptive agents. The core of the capsule is filled with therapeutically effective amount of a second drug(s), a dietary supplement, minerals, a complexing agent and other excipients. With the help of FIG. 2, the invention can be very well understood easily. Drugs A and B are selected from the group of oral contraceptives, but are not limited to, Cyproterone acetate, Estradiol, Oestradiol, Norethindrone acetate, Ethinyl Estradiol, Levonorgestrel, Dienogest, Drospirenone, Desogestrel, Ethynodiol, Diacetate, Mestranol, Nomegestrol acetate, Norgestrel, Norgestimate, Dienogest, Norelgestromin, Norethisterone, Gestodene, Oestradiol valerate, and Ethynodiol diacetate.

Owner:JOSHI HEMANT N +1

Clean workshop antibiosis sheet material

ActiveCN103465550AImprove cleanlinessImprove antibacterial propertiesMetal layered productsSodium stearateAdipic acid

The invention relates to a clean workshop antibiosis sheet material, which employs cold rolling steel plate as inner layer and antibiosis coating as external layer, and the coating is composed of the following components by weight: 19-22 parts of carboxymethyl chitosan, 14-17 parts of copper powder, 5-6 parts of zinc powder, 8-15 parts of sodium stearate, 5-11 parts of adipic acid, 16-21 parts of urea-formaldehyde resin, 11-17 parts of ethylene acetate. The prepared clean workshop antibiosis sheet material has good antibiosis effect.

Owner:江苏悠谷未来科技有限公司

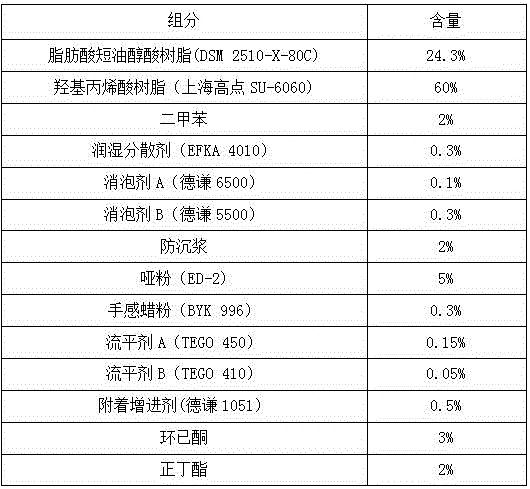

PU high-fullness matte varnish for melamine board

InactiveCN105733435AImprove fullnessImprove adhesionPolyurea/polyurethane coatingsCyclohexanoneAcrylic resin

The invention relates to a PU high-fullness matte varnish for melamine boards, which belongs to the technical field of wood coating manufacturing. The PU high-fullness matte varnish for melamine boards of the present invention is composed of components A, B and C according to the weight ratio of 1:0.5:0.5-0.7; wherein component A is composed of fatty acid short oil alkyd resin, hydroxyacrylic acid Resin, xylene, wetting and dispersing agent, defoamer A, defoamer B, anti-settling slurry, matte powder, wax powder, leveling agent A, leveling agent B, adhesion promoter, cyclohexanone and n-butyl ester Composition; B component is composed of TDI trimer curing agent, TDI prepolymer, HDI trimer curing agent, xylene and n-butyl acetate; C component is composed of xylene, n-butyl acetate, propylene glycol methyl ether acetate It is composed of ester, cyclohexanone, and ethylene glycol diacetate; it significantly improves the fullness, adhesion, yellow resistance, and flexibility of matte clear topcoats. The PU high-fullness matte clear finish paint for melamine boards of the present invention can be directly sprayed on melamine boards.

Owner:山东巴德士新材料有限公司

Implant having a core and a tube encasing the core

InactiveUS20130297040A1Promote localizationEasy to disassembleOrganic active ingredientsPeptide/protein ingredientsEthinyl oestradiolBULK ACTIVE INGREDIENT

The present invention relates to an implant comprising: —a core material comprising polydimethylsiloxane or at least one hydrogel polymer; —a tube encasing said core material comprising an ethylene vinyl acetate polymer or at least one hydrogel polymer; —a sealant for closure of the open ends of said tube comprising polydimethylsiloxane or a mono-, di-, or triacetoxy derivative thereof, or at least one hydrogel polymer; and —at least one active ingredient; wherein said at least one active ingredient is selected from the group comprising celecoxib, sulindac, tamoxifen, oestrogen, oestradiol, ethinyl oestradiol, mestranol, dienogest, norgestrel, levonorgestrel, desogestrel, norgestimate, ethynodiol diacetate, leuprorelin, buserelin, gonrelin, triptorelin, nafarelin, deslorelin, histrelin, and supprelin; and with the proviso that when the sealant is said at least one hydrogelpolymer, the core material comprises polydimethylsiloxane. Furthermore, the invention relates to an implant for use as a medicament. In particular, the invention relates to an implant for use in the treatment of endometriosis.

Owner:UNIV LIEGE +1

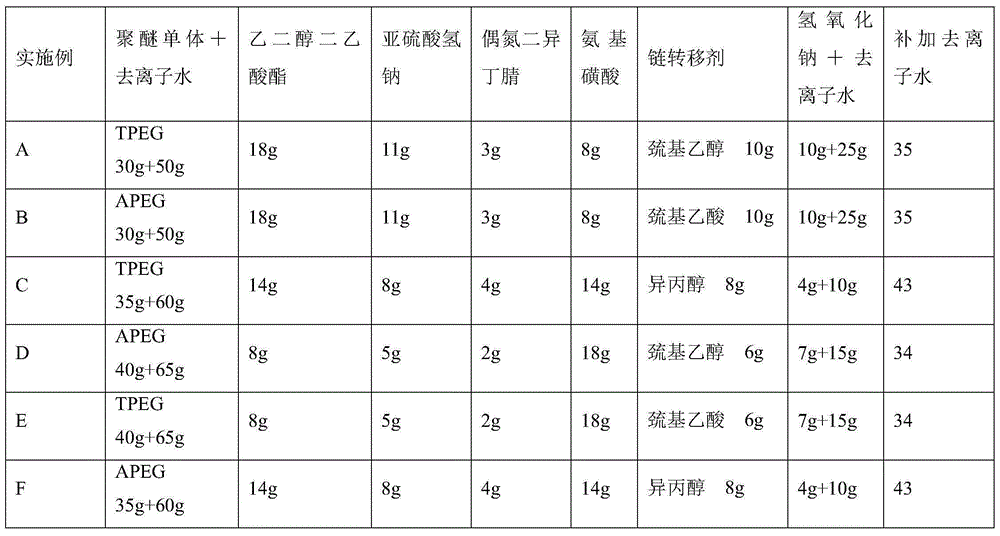

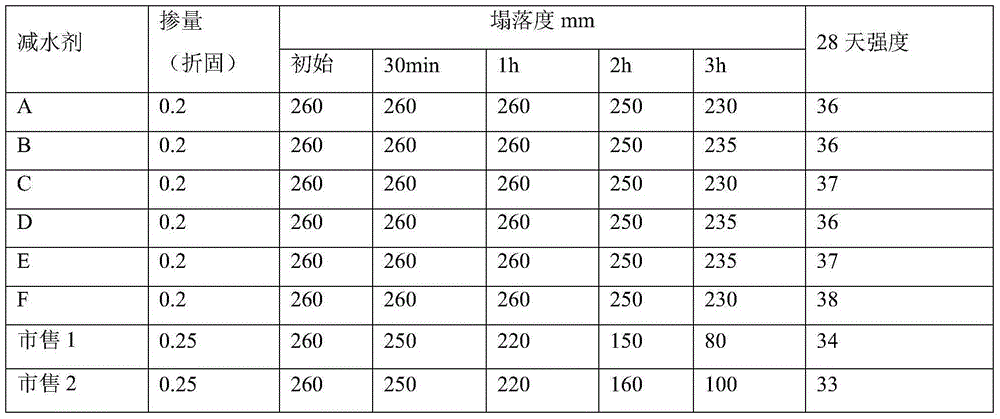

High-liquidity polycarboxylic acid water reducing agent and preparation method thereof

The invention particularly relates to a high-liquidity polycarboxylic acid water reducing agent which comprises 15-20% of polyether monomer, 4-9% of ethylene glycol diacetate, 3-5% of a chain transfer agent, 4-9% of sulfamic acid, 2.5-5.5% of sodium bisulfite, 1-2% of azobisisobutyronitrile, 2-5% of sodium hydroxide and the balance of deionized water. A preparation method for the high-liquidity polycarboxylic acid water reducing agent comprises the following steps: (1), adding the polyether monomer and deionized water into a reaction kettle, uniformly stirring for completely dissolving, and heating to 60+ / - 2 DEG C; (2), adding sodium bisulfate and ethylene glycol diacetate, continuously stirring for 30 min, after complete dispersing, adding azobisisobutyronitrile and sulphamic acid, heating to 80+ / - 2 DEG C and reacting for 30 min; (3), adding the chain transfer agent, wherein the chain transfer agent is added into the reaction kettle for five times at the interval of 10 min; (4), continuously reacting for 3 h, cooling to room temperature, adding deionized water for dissolving sodium hydroxide so as to adjust pH to 7.0; finally, replenishing deionized water, and continuously stirring for 30 min so as to obtain the water reducing agent. By adopting the water reducing agent provided by the invention, the problem that concrete collapses due to high air temperature, long transport time and other factors is solved.

Owner:XINJIANG DELAND

Polyvinyl acetate emulsion and preparation method thereof

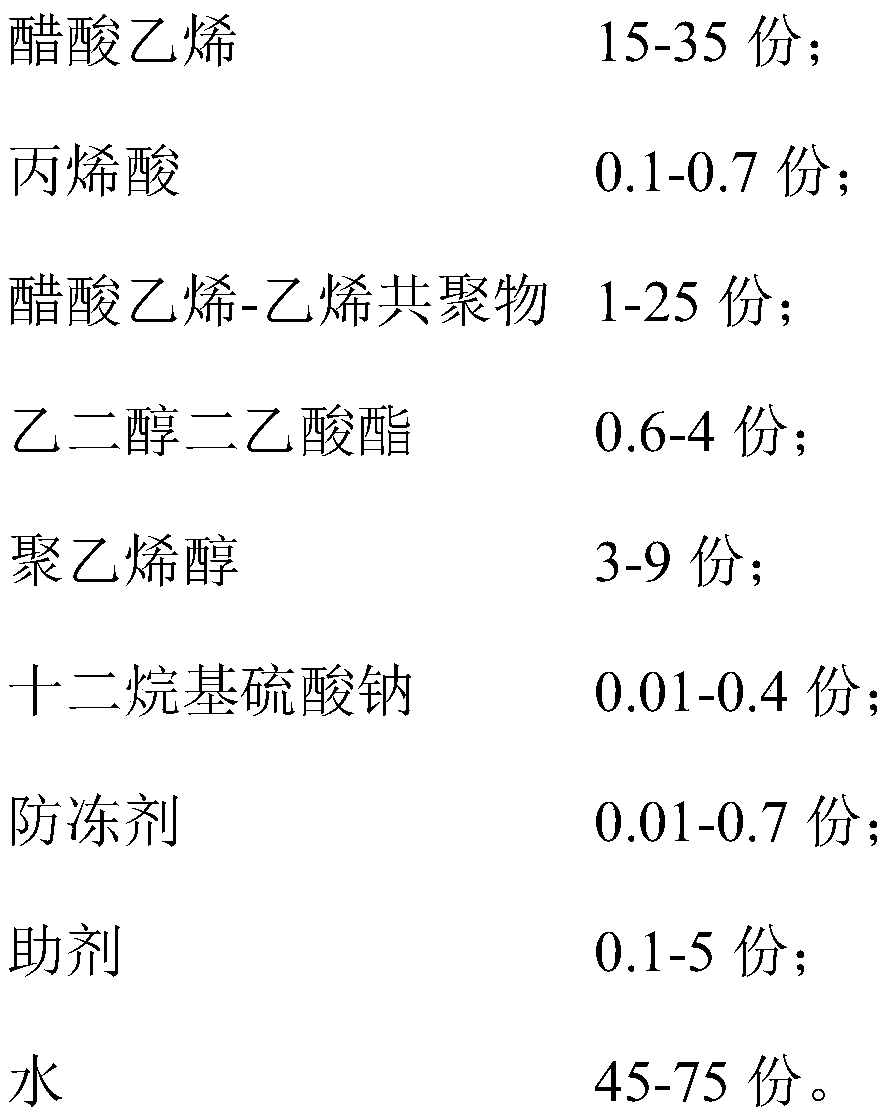

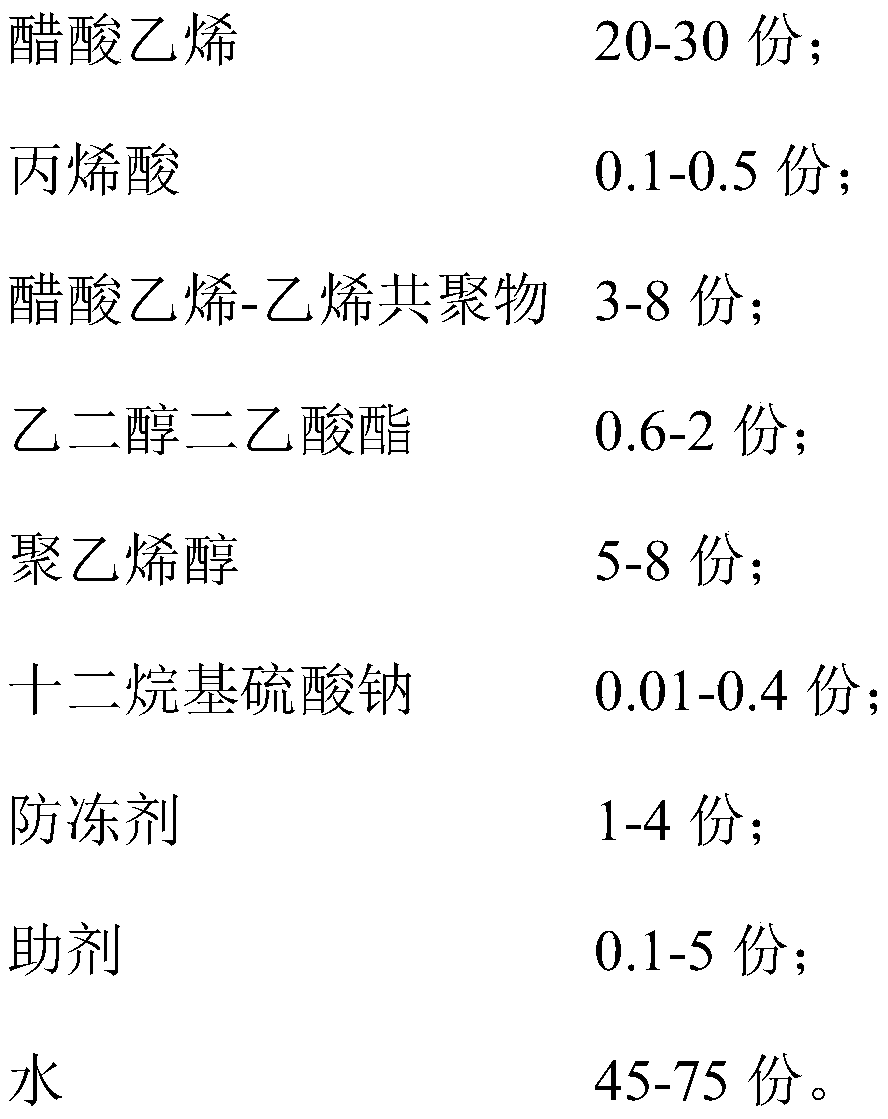

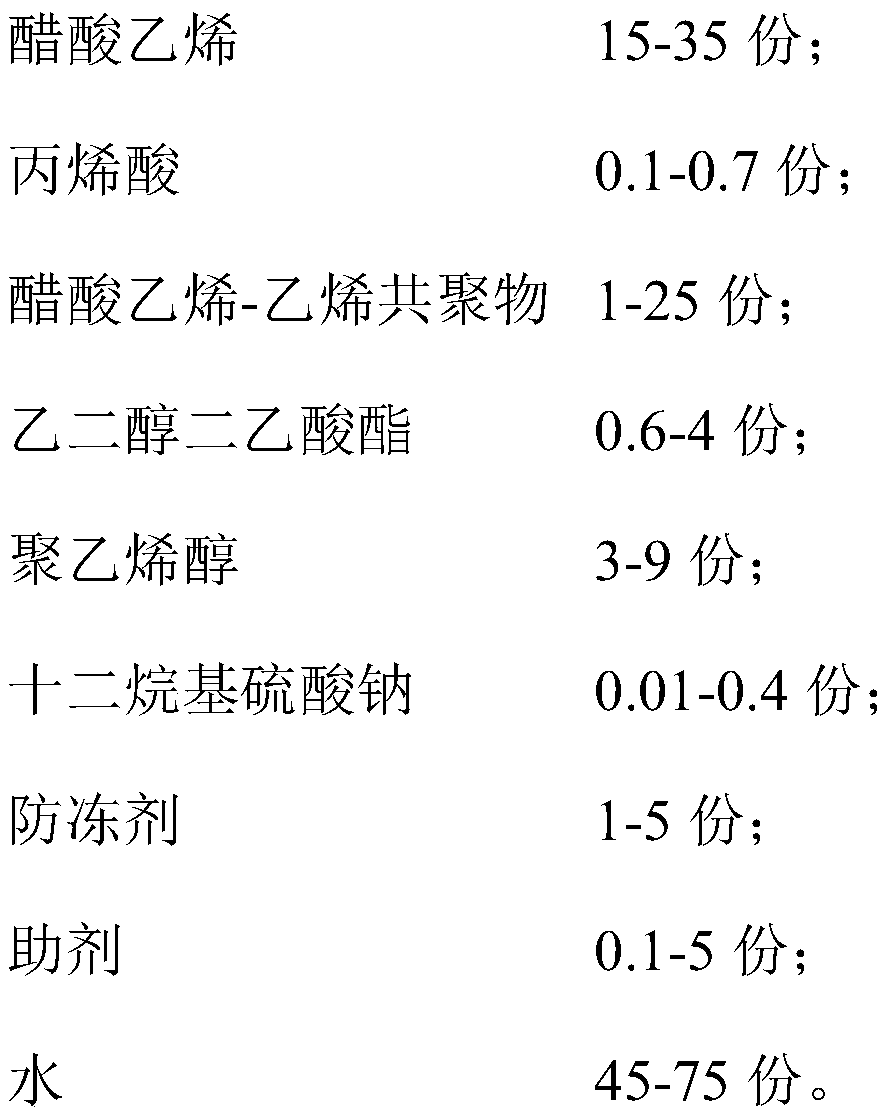

ActiveCN110055015AIncrease viscosityHigh bonding strengthMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesEthylene glycol bisPolyvinyl alcohol

The invention relates to a polyvinyl acetate emulsion and a preparation method thereof. The polyvinyl acetate emulsion is prepared from, by weight, 15-35 parts of polyvinyl acetate, 0.1-0.7 part of acrylic acid, 1-25 parts of a vinyl acetate-ethylene copolymer, 0.6-4 parts of ethylene glycol diacetate, 3-9 parts of polyvinyl alcohol, 0.01-0.4 part of lauryl sodium sulfate, 0.01-0.7 part of an anti-freezing agent, 0.1-5 parts of auxiliary agents and 45-75 parts of water. In the polyvinyl acetate emulsion, contents of formaldehyde and TVOC (total volatile organic compound) are less than nationalstandards of China, APEO (alkylphenol ethoxylates) and phthalate are avoided, and foreign limitation standards are met.

Owner:广东嘉宝莉科技材料有限公司

Clean workshop antibiosis sheet material

ActiveCN103465550BImprove cleanlinessImprove antibacterial propertiesMetal layered productsAntibiosisSodium stearate

Owner:江苏悠谷未来科技有限公司

A high-volume, high-volume, impact-resistant polyurethane matt clear finish

A high-volume impact-resistant polyurethane matt clear finish of the present invention is prepared from castor oil alkyd resin, 20% vinyl acetate resin plus wax powder and matte powder to prepare component A, and TDI adduct curing agent L-75 , TDI trimer curing agent 1451, HDI trimer curing agent HX-90B and dehydrated n-butyl acetate, xylene to prepare component B, with n-butyl acetate, propylene glycol methyl ether acetate, ethyl acetate, ethyl Glycol diacetate and xylene are prepared as component C of the diluent during construction, which is prepared by mixing components A, B, and C at a weight ratio of 1:0.5:0.5-0.8. The invention utilizes castor oil alkyd resin, HDI hexamethylene diisocyanate and other raw materials with high solid content and good flexibility to improve the flexibility and impact resistance of the paint film, so that the coating after painting has good transparency, high fullness, Excellent flexibility and impact resistance, very suitable for coating wooden crafts and rattan furniture.

Owner:GUANGDONG BADESE CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com