Recycling and separating process of heavy component residual liquid in carbonylation production process of acetic acid

A heavy component and carbonylation technology, which is applied in the separation/purification of carboxylic acid compounds, the preparation of organic compounds, organic chemistry, etc., can solve the problems of resource waste, environmental pollution, etc., and achieve simple process, efficient recovery and separation process, increase The effect of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

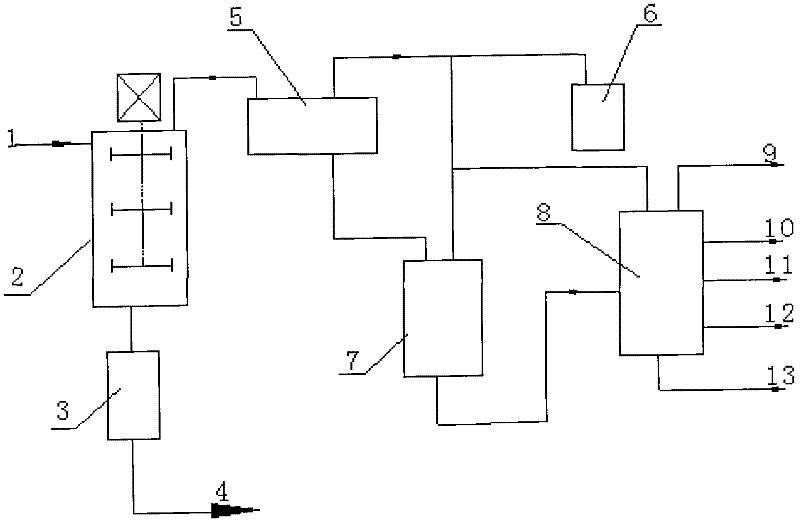

[0021] Such as figure 1 As shown in the process flow diagram, the heavy acetic acid waste liquid is entered into the wiped film evaporator 2 from the raw material 1 at a flow rate of 3.8ml / min, the vacuum system 6 is opened, and the pressure of the wiped film evaporator 2 system is controlled at 3.0KPa. The plate rotation speed is adjusted to 30 rpm, the outlet temperature of the liquid at the bottom is 145°C, the heavy polymer component 4 is discharged from the bottom to the buffer tank 3, and then the residual liquid 13 of the tower kettle is removed from the boundary area, and the acetic acid content is less than 200ppm; at the same time, the light component at the top After being condensed by the condenser 5, the fraction enters the light component intermediate tank 7, and then enters the batch rectification unit 8 for reflux ratio operation. The system pressure is controlled at 5.0KPa. After about 1 hour after the total reflux is stabilized, the specific operations are as ...

Embodiment 2

[0028] Such as figure 1 As shown in the process flow diagram, the heavy acetic acid waste liquid is entered into the wiped-film evaporator 2 from the raw material 1 at a flow rate of 4.5ml / min, and the vacuum system 6 is opened to control the pressure of the wiped-film evaporator 2 system at 4.0KPa. The plate rotation speed is adjusted to 40 rpm, the outlet temperature of the liquid at the bottom is 150°C, the heavy polymer component 4 is discharged from the bottom to the buffer tank 3, and then the residual liquid 13 of the tower kettle is discharged outside the boundary area, and the acetic acid content is less than 420ppm; at the same time, the light component at the top After being condensed by the condenser 5, the fraction enters the light component intermediate tank 7, and then enters the batch rectification unit 8 for reflux ratio operation. The system pressure is controlled at 6.0KPa. After about 1.5 hours after the total reflux is stabilized, the specific operations ar...

Embodiment 3

[0035] Such as figure 1 As shown in the process flow diagram, the heavy acetic acid waste liquid is entered into the wiped film evaporator 2 from the raw material 1 at a flow rate of 4ml / min, the vacuum system 6 is opened, the pressure in the wiped film evaporator 2 is controlled at 5.3KPa, and the scraper The rotating speed is adjusted to 35 rpm, the outlet temperature of the liquid at the bottom is 146°C, the heavy polymer component 4 is discharged from the bottom to the buffer tank 3, and then the residual liquid 13 of the tower kettle is discharged outside the boundary area, and the acetic acid content is less than 200ppm; at the same time, the light component at the top After being condensed by the condenser 5, it enters the light component intermediate tank 7, and then enters the batch rectification unit 8 for reflux ratio operation. The system pressure is controlled at 5.1KPa. After about 1.2 hours after the total reflux is stable, the specific operation is as follows: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com