PU high-fullness matte varnish for melamine board

A melamine board and fullness technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problem of poor fullness, hardness and flexibility of polyurethane paint, which cannot meet the requirements of furniture feel and fullness, and increase the cost of manpower and material resources for furniture factories and other problems, to achieve the effect of excellent hand feeling, improvement of fullness and adhesion, and high fullness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

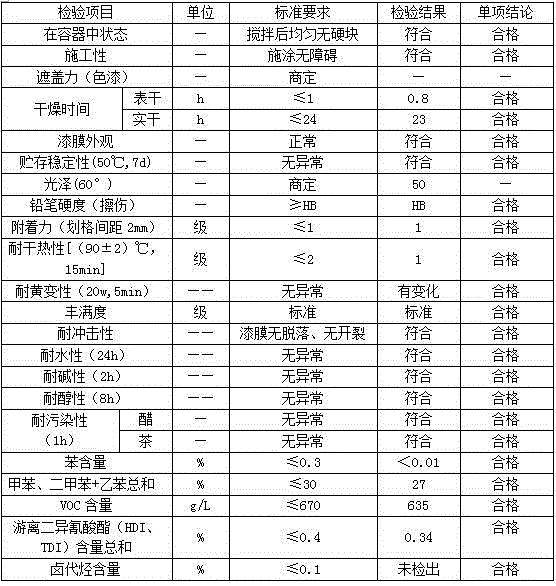

Image

Examples

Embodiment 1

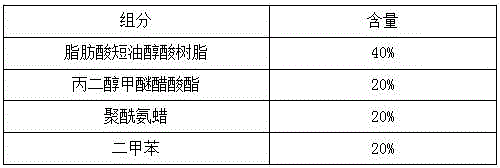

[0049] 1) Preparation of anti-settling slurry:

[0050] Prepare raw materials according to the following mass percentages;

[0051] Fatty acid short oil alkyd resin 40%

[0052] Propylene glycol methyl ether acetate 20%

[0054] Xylene 20%;

[0055] The fatty acid short oil alkyd resin is a resin produced by DSM Synthetic Resin (Foshan) Co., Ltd. (model: 2510X80C, solid content: 80%);

[0056] The polyamide wax is produced by Kusumoto Chemical (model: 6900HV, solid content: 20%);

[0057] Production process: Choose a clean and meet the requirements of the dispersion tank, put in fatty acid short oil alkyd resin, propylene glycol methyl ether acetate, stir evenly at 600-800 revolutions per minute, and put in polyamide wax at 600-800 revolutions per minute. Disperse at a minute speed to the fineness ≤ 25μm, stop adding xylene, stir evenly at a speed of 600-800 revolutions per minute, and then pack it into a barrel for later use.

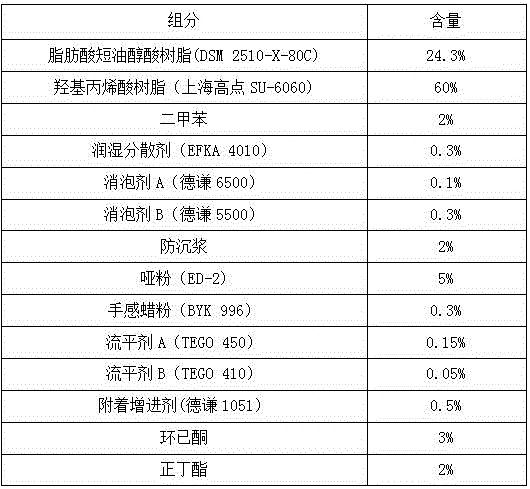

[0058] 2) Preparation of component...

Embodiment 2

[0084] Weigh the raw materials used to prepare the anti-settling, component A, component B and component C according to the following mass percentages (the source of raw materials is the same as in Example 1)

[0085] 1) Anti-settling:

[0086] Fatty acid short oil alkyd resin 40%

[0087] Propylene glycol methyl ether acetate 20%

[0088] Polyamide wax 20%

[0089] Xylene 20%;

[0090] 2) Part A:

[0091] ;

[0092] 3) Part B:

[0093] IL145130%

[0094] SC-7520%

[0095] HXR-90B12%

[0096] Xylene 8%

[0097] 30% n-butyl acetate;

[0098] 4) Component C:

[0099] Xylene 40%

[0100] N-Butyl acetate 10%

[0101] Propylene glycol methyl ether acetate 40%

[0102] Cyclohexanone 8%

[0103] Ethylene glycol diacetate 2%;

[0104] The preparation process of Example 1 is used to prepare component A, component B, and component C; then, component A, component B, and component C are mixed in a weight ratio of 1:0.5:0.8 to obtain the present invention PU high plump matte clear topcoat for melamine board.

Embodiment 3

[0107] A component

[0108] 70% solid content viscosity 50000~70000mpa.s / 25℃ soybean oil alkyd resin: 75 parts

[0109] Xylene: 6 parts,

[0110] Butyl acetate: 10 parts,

[0111] Propylene glycol methyl ether acetate: 8 parts,

[0112] Toluene: 10 parts,

[0113] Leveling agent: 0.1,

[0114] Defoamer: 0.1 part,

[0115] Component B

[0116] Bayer's L-75TDI adduct: 45 parts,

[0117] Bayer's 3390HDI trimer: 12 parts,

[0118] 45 parts of polyurethane grade solvent,

[0119] It is made by mixing the two components of AB at 1:1 uniformly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com