Reactive distillation process for heavy component residue liquid produced in process of producing acetic acid through carbonylation

A technology of reactive distillation and heavy components, which is applied in the chemical industry, preparation of organic compounds, separation/purification of carboxylic acid compounds, etc. The effect of reducing energy consumption and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A kind of reactive distillation process of heavy component raffinate in carbonylation production acetic acid process, comprises the steps:

[0037] 1) Adopt chromatographic analysis to sample and analyze the mass percentage content of acetic acid, ethylene glycol diacetate and acetoxyacetic acid in the heavy component raffinate, according to the hydrolysis or alcoholysis reaction equation of ethylene glycol diacetate and acetyl The hydrolysis reaction equation of oxyacetic acid calculates the amount that ethylene glycol diacetate and acetoxyacetic acid are converted into acetic acid respectively;

[0038] Wherein, in the raffinate of the heavy component, after chromatographic analysis, the content of internal acetic acid is 25wt%, ethylene glycol diacetate is 15wt%, acetoxyacetic acid is 40wt%, and the rest is water and unavoidable impurities.

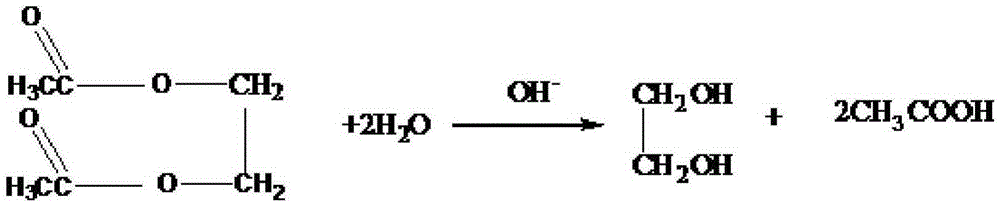

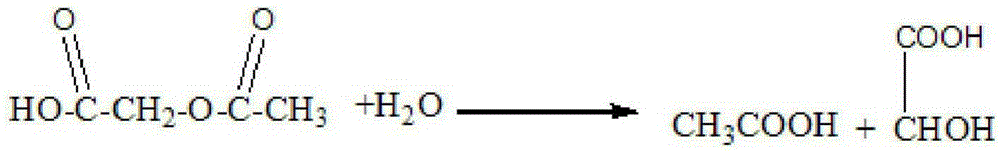

[0039] Ethylene glycol diacetate is easily hydrolyzed to generate ethylene glycol and acetic acid in the presence of caustic a...

Embodiment 2

[0046] In another preferred embodiment of the present invention, in the heavy component raffinate described in step 1), acetic acid: 23wt%, ethylene glycol diacetate: 18wt%, acetoxyacetic acid: 35wt%, the rest is water And unavoidable impurity, all the other are with embodiment 1.

Embodiment 3

[0048] In another preferred embodiment of the present invention, in the heavy component raffinate described in step 1), acetic acid: 28wt%, ethylene glycol diacetate: 20wt%, acetoxyacetic acid: 45wt%, the rest is water And unavoidable impurity, all the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com