High-liquidity polycarboxylic acid water reducing agent and preparation method thereof

A high-slump-preserving, water-reducing agent technology, which is applied in the research and manufacture of concrete admixtures, can solve problems such as long transportation time and loss of concrete slump, and achieve the effect of preventing hydration and prolonging the setting time of cement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

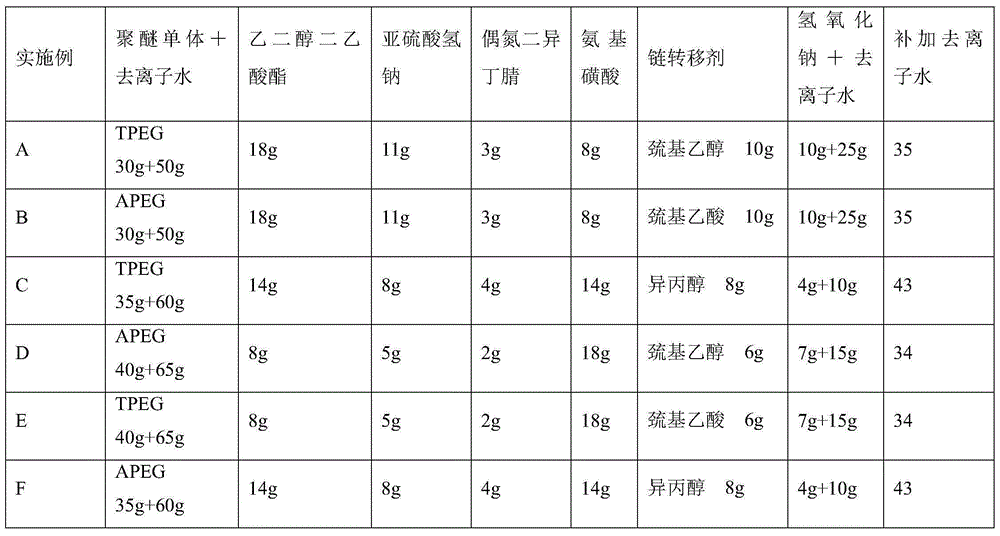

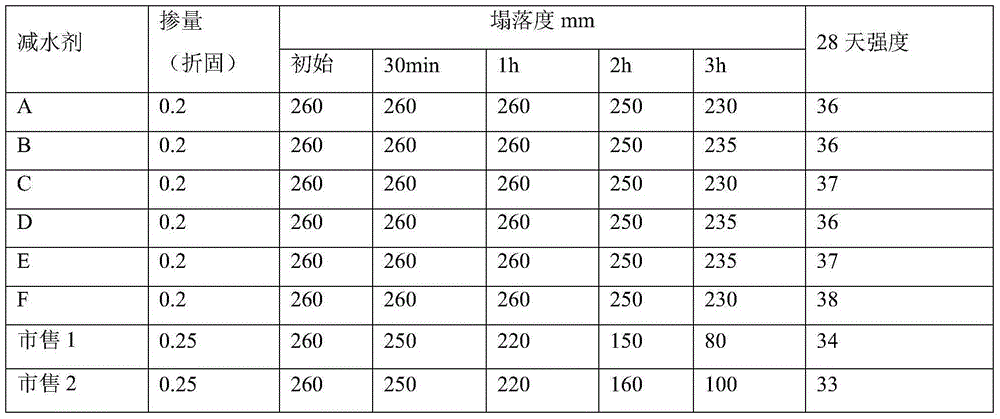

[0011] Table 1 is the proportioning of embodiment A, B, C, D, E and F

[0012] Table 1

[0013]

[0014] The preparation method of the high slump-retaining polycarboxylate water reducer described in the above-mentioned embodiment A-F comprises the following steps:

[0015] (1) Add the polyether monomer and an appropriate amount of deionized water into the reaction kettle, stir evenly to completely dissolve the polyether monomer in the deionized water, heat up to 60±2°C, and set aside;

[0016] (2) Add sodium bisulfite and ethylene glycol diacetate to step (1), continue stirring for 30 minutes, add azobisisobutyronitrile and sulfamic acid after complete dispersion, heat up to 80±2°C, and react 30min, standby;

[0017] (3) Add chain transfer agent in step (2), chain transfer agent is added in the reactor in 5 times, and the time interval is 10min;

[0018] (4) After adding the chain transfer agent in step (3), continue to react for 3h, then, cool to room temperature, add a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com