Water-soluble sticking cloth resin cleaning agent and preparation method thereof

A cleaning agent and water-soluble technology, applied in the field of water-soluble adhesive patch resin cleaning agent and its preparation, can solve the problems of easy explosion, floating on the water surface, endangering the health of operators, etc. Clear effect, excellent water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A water-soluble plaster resin cleaning agent, the parts by weight of each component in its formula are as follows:

[0038] Propylene glycol methyl ether acetate 2%

[0039] Glyceryl Triacetate 28%

[0040] Ethylene Glycol Diacetate 70%.

[0041] Preparation of water-soluble patch resin cleaning agent:

[0042] (1) Add 70% ethylene glycol diacetate into the reactor at normal temperature and pressure;

[0043] (2) At normal temperature and pressure, add 28% glycerol triacetate into the reactor and mix it with ethylene glycol diacetate. While adding the material, start mechanical stirring, control the speed at 100r / min, stir for 10 minutes and mix evenly to obtain the first a mixture;

[0044] (3) At normal temperature and pressure, slowly add 2% propylene glycol methyl ether acetate into the reactor to mix with the first mixture, stir at 100r / min for 8 minutes, and filter through a filter to obtain a water-soluble patch resin cleaning agent .

[0045] Estimate by r...

Embodiment 2

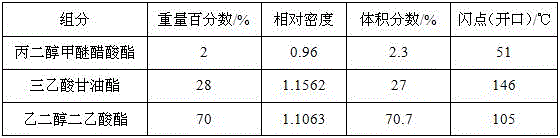

[0049] A water-soluble plaster resin cleaning agent, the parts by weight of each component in its formula are as follows:

[0050] Propylene glycol methyl ether acetate 2%

[0051] Glyceryl Triacetate 23%

[0052] Ethylene Glycol Diacetate 75%.

[0053] Preparation of water-soluble patch resin cleaning agent:

[0054](1) Add 75% ethylene glycol diacetate into the reactor at normal temperature and pressure;

[0055] (2) At normal temperature and pressure, add 23% glycerol triacetate into the reactor to mix with ethylene glycol diacetate, start mechanical stirring at the same time, control the speed of 100r / min, stir for 10min and mix evenly to obtain the first a mixture;

[0056] (3) At normal temperature and pressure, slowly add 2% propylene glycol methyl ether acetate into the reactor to mix with the first mixture, stir at 100r / min for 8 minutes, and filter through a filter to obtain a water-soluble patch resin cleaning agent .

[0057] Estimated flash point by recipe: ...

Embodiment 3

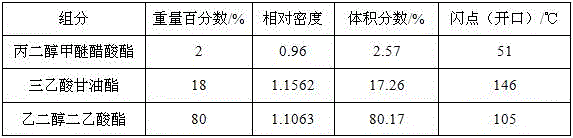

[0061] A water-soluble plaster resin cleaning agent, the parts by weight of each component in its formula are as follows:

[0062] Propylene glycol methyl ether acetate 2%

[0063] Glyceryl Triacetate 18%

[0064] Ethylene Glycol Diacetate 80%.

[0065] Preparation of water-soluble patch resin cleaning agent:

[0066] (1) Add 80% ethylene glycol diacetate into the reactor at normal temperature and pressure;

[0067] (2) At normal temperature and pressure, add 18% glycerol triacetate into the reactor and mix it with ethylene glycol diacetate. While adding the material, start mechanical stirring, control the rotation speed at 100r / min, stir for 10 minutes and mix evenly to obtain the first a mixture;

[0068] (3) At normal temperature and pressure, slowly add 2% propylene glycol methyl ether acetate into the reactor to mix with the first mixture, stir at 100r / min for 8 minutes, and filter through a filter to obtain a water-soluble patch resin cleaning agent .

[0069] Esti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com