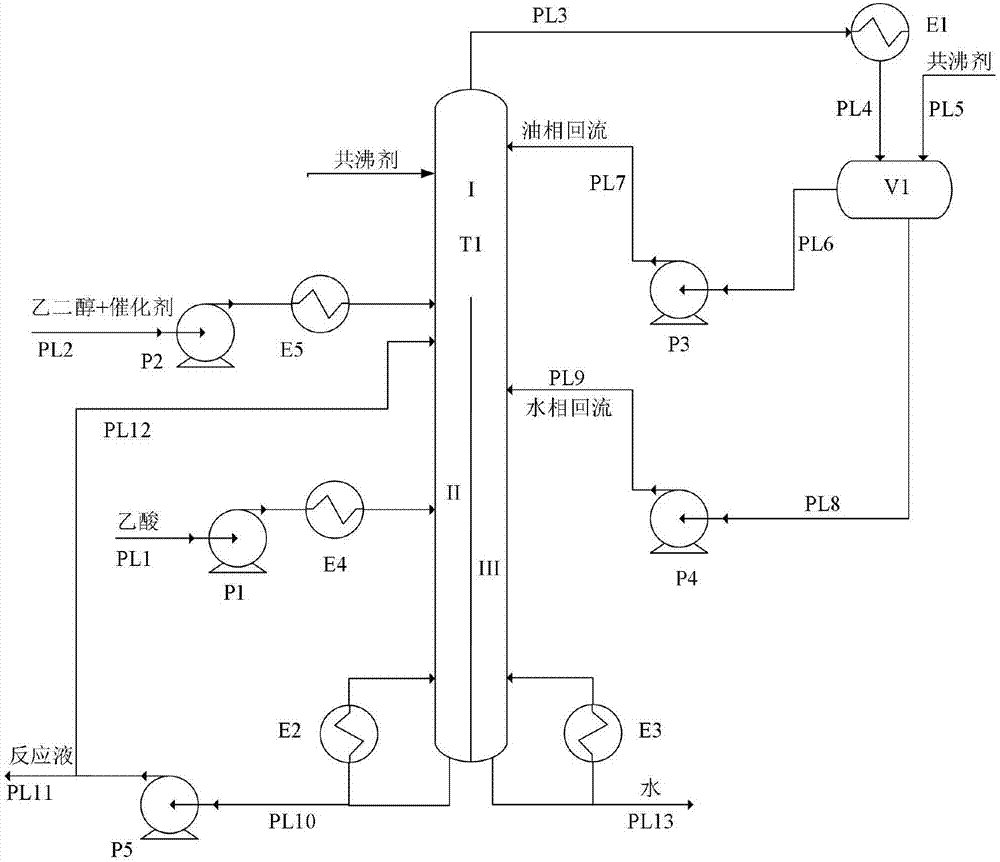

Device and method for producing ethylene glycol diacetate by adopting dividing-wall reaction rectifying column

A technology of reactive distillation column and ethylene glycol 2 is applied in the field of producing ethylene glycol diacetate in a dividing wall reactive distillation column, and can solve the problem of high content of ethylene glycol monoacetate, low conversion rate, problems such as low production capacity, to achieve the effect of improving the conversion rate of reactants and product yield, reducing energy consumption and equipment investment, and saving equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The dividing wall reactive distillation column T1 is a packed column with a tower diameter of 50mm. The material of the tower body and the packing are 2205 stainless steel. The packing type is φ3×3 θ ring packing. The tower height is 4m. The number of theoretical plates of the stripping section II of the main tower and the stripping section III of the auxiliary tower is 26, and the cross-sectional area ratio of the stripping section III of the auxiliary tower and the stripping section II of the main tower is 0.06.

[0053] The raw material acetic acid is preheated from the feed temperature of 32°C to 117°C and then enters the tower with a flow rate of 9g / min. The raw material ethylene glycol is preheated from the feed temperature of 32°C to 105°C and then enters the tower with a flow rate of 3g / min. Benzenesulfonic acid is a catalyst, and the consumption accounts for 3% of the feed amount of ethylene glycol, and toluene is an entrainer. The operating conditions of the d...

Embodiment 2

[0055] The dividing wall reactive distillation column T1 is a packed column with a tower diameter of 40 mm. The material of the tower body and packing is 2205. The packing type is φ3×3 θ ring packing. The tower height is 5 m. The theoretical plate number of the common rectifying section I is 32 blocks, the number of theoretical plates of the stripping section II of the main tower and the stripping section III of the auxiliary tower is 30, and the cross-sectional area ratio of the stripping section III of the auxiliary tower and the stripping section II of the main tower is 0.06.

[0056]The raw material acetic acid is preheated from the feed temperature 32°C to 117°C and then enters the tower, and the flow rate is 6g / min. Benzenesulfonic acid was used as a catalyst, and the dosage accounted for 3.5% of the ethylene glycol feed amount, and toluene was used as an entrainer. The operating conditions of the dividing wall reactive distillation column T1: the pressure at the top of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com