Three-dimensional rapid formed composite powder material

A composite powder and fast technology, applied in the field of 3D printing, can solve problems affecting printing efficiency and printing accuracy, environmental pressure, high production cost pressure, etc., and achieve the effects of improving printing efficiency, high compressive strength, and enhancing fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

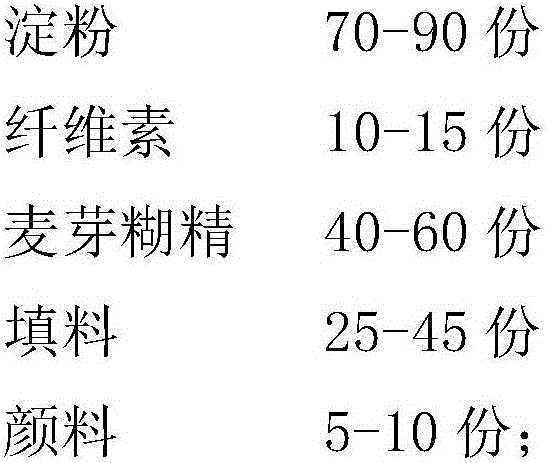

[0028] Example 1 discloses a composite powder material, which is used in a three-dimensional rapid prototyping printer, and the formula of the material is shown in Table 1.

[0029] Formulation table in table 1 embodiment 1

[0030]

Embodiment 2

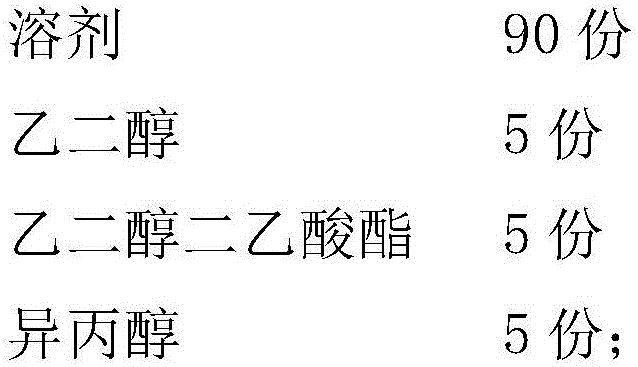

[0032] Example 2 discloses a composite powder material, which is used in a three-dimensional rapid prototyping printer, and the formula of the material is shown in Table 2.

[0033] Formulation table in table 1 embodiment 2

[0034]

[0035]

Embodiment 3

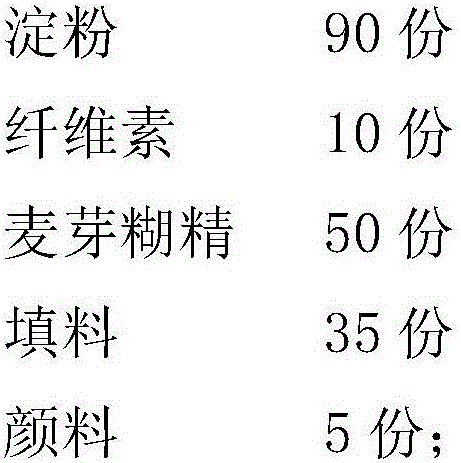

[0037] In Example 3, a composite powder material is developed, which is applied in a three-dimensional rapid prototyping printer, and the formula of the material is shown in Table 3.

[0038] Formulation table in table 3 embodiment 3

[0039]

[0040] Among them, the filler in the above-mentioned embodiment 1-3 can be selected from calcium carbonate, barium sulfate, talcum powder, and fumed silica; the above-mentioned pigment can be selected from carbon black, iron oxide red, titanium dioxide, phthalocyanine blue; the above-mentioned solvent can be selected from distilled water , methanol, ethanol, propanol.

[0041] The particle size of the above-mentioned starch is selected from 1-10 μm, the particle size of the above-mentioned cellulose is selected from 50-100 μm, the particle size of the above-mentioned maltodextrin is selected from 100-300 μm, and the starch base composed of the above-mentioned starch, cellulose, maltodextrin, filler and pigment The particle size of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com