Polyvinyl acetate emulsion and preparation method thereof

A technology of polyvinyl acetate milk and vinyl acetate, applied in the direction of monocarboxylate copolymer adhesives, adhesive types, adhesive additives, etc., can solve problems such as endangering human hormone function, affecting human health, and toxic effects , to achieve the effect of simple and easy-to-operate preparation method, suitable for large-scale production, and good bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The preparation method of polyvinyl acetate emulsion is as follows:

[0052] Mixing the vinyl acetate and acrylic acid to obtain a monomer mixture;

[0053] adding the polyvinyl alcohol into water, heating to dissolve, lowering the temperature, adding sodium lauryl sulfate and a part of the monomer mixture, and polymerizing at heat preservation to obtain the first system;

[0054] Add the remaining part of the monomer polymer dropwise to the first system and keep warm to obtain the second system;

[0055] Add the ethylene glycol diacetate and antifreeze to the second system, vacuumize, add vinyl acetate-ethylene copolymer, mix evenly, and obtain.

[0056] It can be understood that according to the conventional use method of auxiliary agents, auxiliary agents such as crosslinking agent, initiator, pH regulator, chelating agent, reducing agent and preservative can be appropriately added in the above preparation method.

Embodiment 1-3

[0058] With reference to the raw materials and dosages in Table 1, and with reference to the following preparation methods and the process parameters in Table 2, the polyvinyl acetate emulsions of Examples 1-3 were prepared.

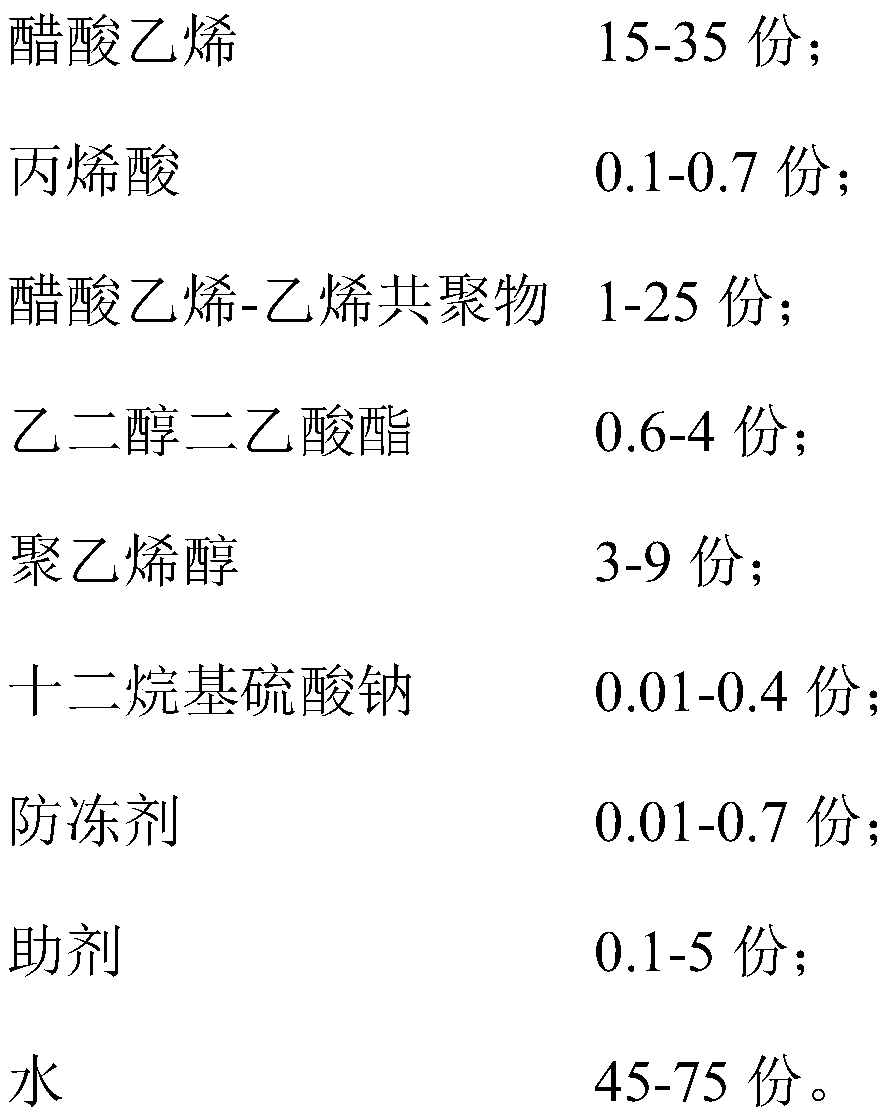

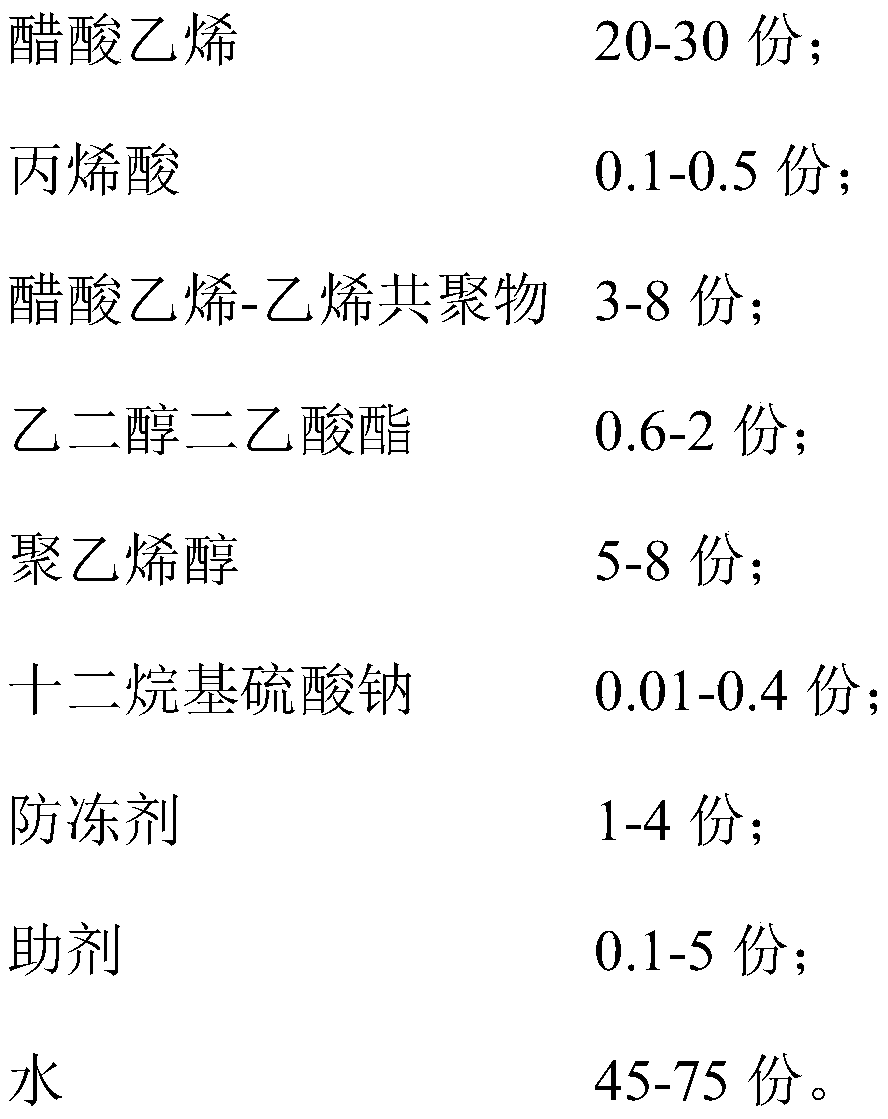

[0059] Table 1

[0060]

[0061] The preparation method of polyvinyl acetate emulsion is as follows:

[0062] (1) Mix vinyl acetate and acrylic acid at room temperature and stir slightly to obtain a monomer mixture;

[0063] (2) Add polyvinyl alcohol and defoamer to water in sequence, start stirring, heat up to 90°C-95°C and keep it warm for 1h-3h;

[0064] (3) Cool down to 70°C to 85°C, add initiator, chelating agent, crosslinking agent, sodium lauryl sulfate, pH regulator and a part of the monomer mixture in sequence, the part of the monomer mixture accounts for the monomer 15% to 45% of the total mass of the mixture, heat preservation reaction for 20min to 60min;

[0065] (4) Add the remaining monomer mixture dropwise to the above system while s...

Embodiment 1 and Embodiment 4-8

[0072] With reference to the raw materials and consumption of Table 3, and using the same preparation method and process parameters as in Example 1, the polyvinyl acetate emulsion of Example 4-7 was prepared, and with reference to the raw materials and consumption of Example 8 of Table 3, the polyvinyl acetate emulsion of Example 8 was prepared. Polyvinyl acetate emulsion, wherein, in the preparation method, omit the step of vacuumizing in step (6), other steps are identical with embodiment 1.

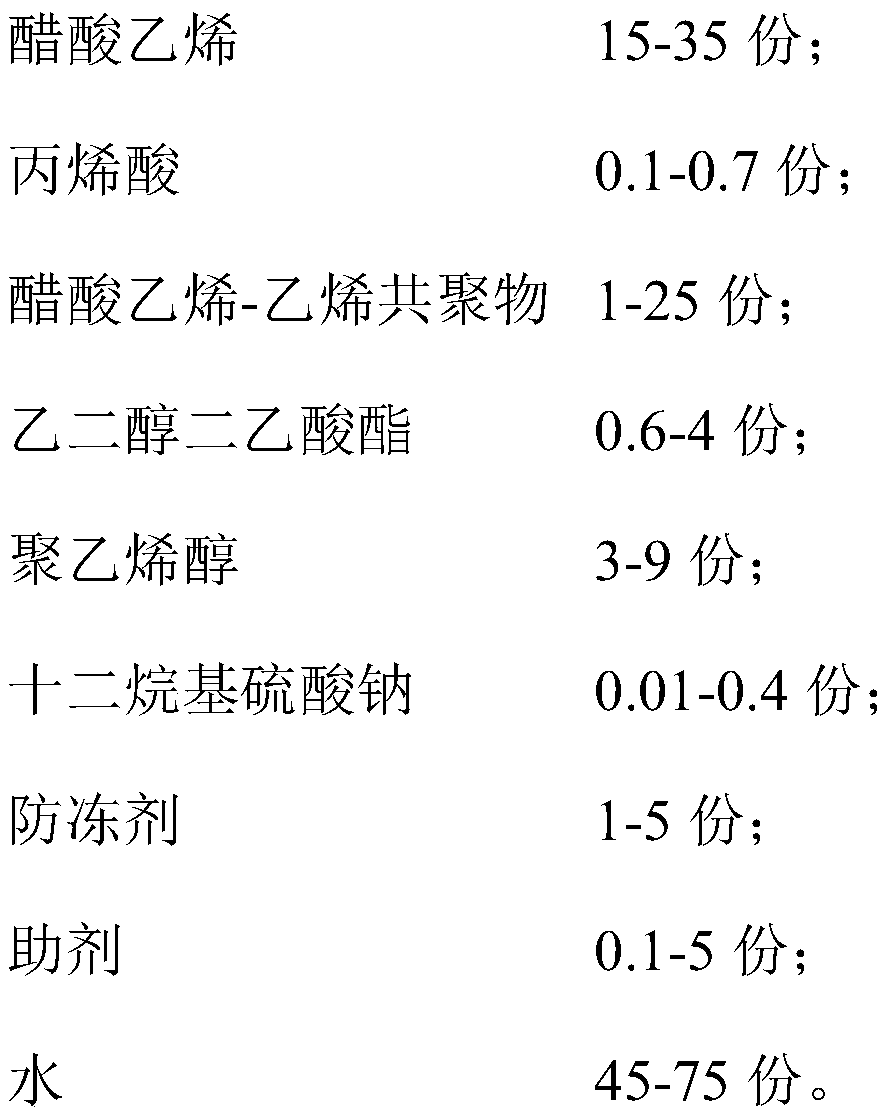

[0073] table 3

[0074]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com