Asbestos-based laminate, manufacturing method and application thereof

A manufacturing method and technology of laminates, applied in chemical instruments and methods, layered products, metal layered products, etc., can solve problems such as lack of performance, achieve excellent self-lubrication and resilience, improve affinity, and resist The effect of peeling and mechanical strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0032] According to a first embodiment of the present invention, it relates to an asbestos-based composite.

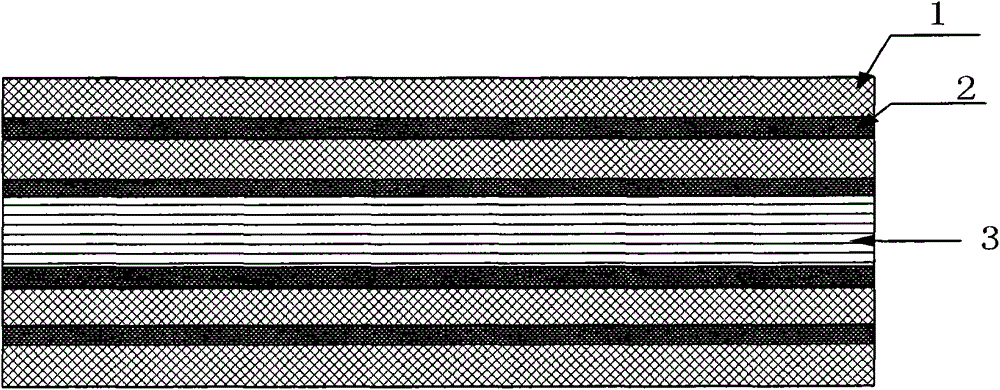

[0033] According to the present invention, the longitudinal section of the asbestos-based composite has a layered structure, and at least includes an asbestos fiber-carbon fiber composite layer and graphite powder layers (hereinafter sometimes referred to as "primary graphite powder layer" to distinguish it from the "additional graphite powder layer" described below). Therefore, the asbestos-based composite of the present invention includes at least one asbestos fiber-carbon fiber composite layer and one or two main graphite powder layers. From the perspective of further improving its self-lubricating and resilience properties, it is preferred that the asbestos-based composite includes at least one asbestos fiber-carbon fiber composite layer and two main graphite powder layers, wherein the two main graphite powder layers layers are respectively located on both sides o...

Embodiment 1

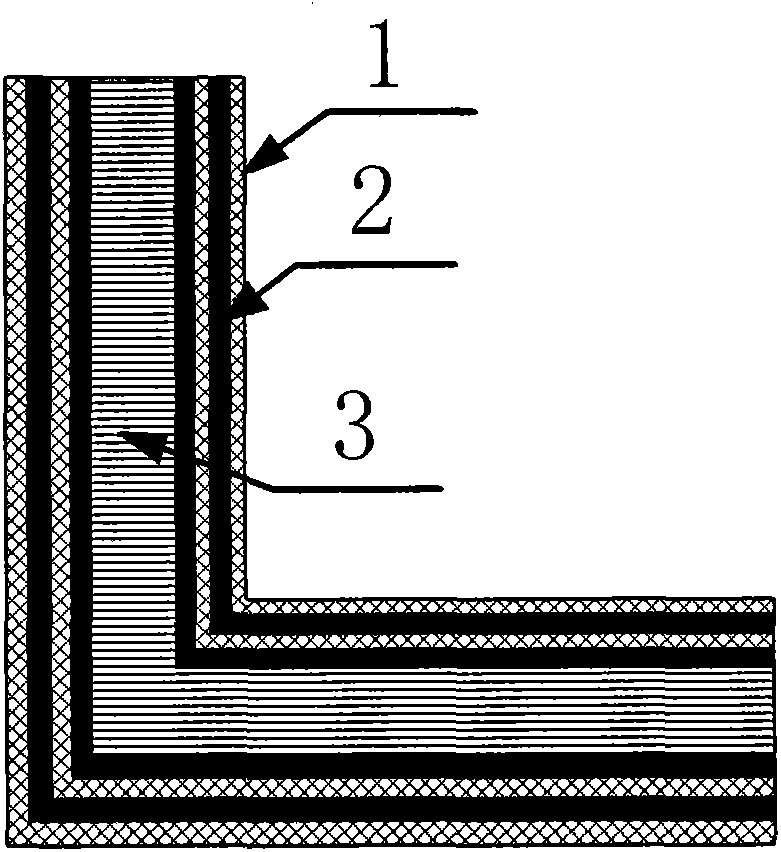

[0099] Follow the steps below to manufacture figure 2 Asbestos based gasket of construction shown.

[0100] 1) Cut the asbestos fiber / rubber composite board (1.0mm thick, XB450 produced by Hebei Hengda Sealing Material Co., Ltd.) of appropriate width with a shearing machine, and cut the carbon fiber cloth of the same width (0.3mm thick, Japan Toray T400HB- 6000-40D), the total width of each blank is greater than the length of the L-shaped section;

[0101] 2) Using folding machine according to figure 2 Fold the asbestos fiber / rubber composite board as shown, and press the positioning groove;

[0102] 3) Apply the high-temperature-resistant adhesive (THC-400 type high-temperature-resistant phenolic resin adhesive) evenly on the upper surface of the asbestos fiber / rubber composite board and one surface of the carbon fiber cloth;

[0103] 4) Align and fit the asbestos fiber / rubber composite board and the carbon fiber cloth so that their respective adhesive-coated surfaces fa...

Embodiment 2

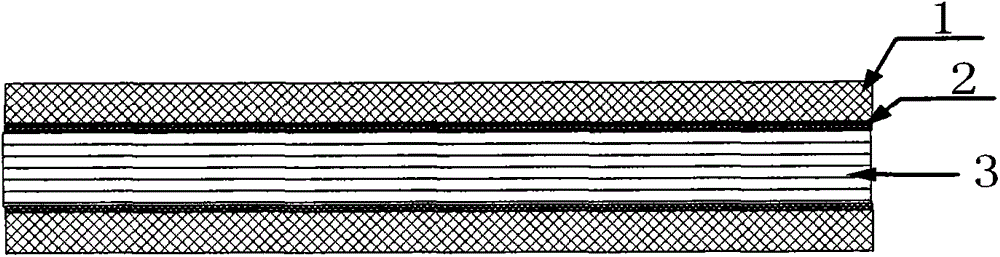

[0117] Follow the steps below to manufacture image 3 Asbestos based gasket of construction shown.

[0118] 1. Making a rock-carbon mixed layer

[0119] 1-1. Combine 15 parts by weight of asbestos fiber (grade 5-70 asbestos produced by Dacheng County Tongda Sealing Material Co., Ltd., in line with GB / T8071-2001) and 5 parts by weight of carbon fiber (length 10-30mm, manufactured by Toray Corporation of Japan) T400 general-purpose carbon fiber) were impregnated with KH550 silane coupling agent, and then dried and loosened respectively;

[0120] After dissolving 1-2.20 parts by weight of liquid nitrile rubber (X730 produced by Dezhou Yida Trading Co., Ltd.) in 10 parts by weight of ethyl acetate, add 20 parts by weight of calcium carbonate filler and an appropriate amount of vulcanizing agent and vulcanization accelerator, and then mix To uniformity, obtain the rubber mixture;

[0121] 1-3. Add the asbestos fiber and carbon fiber treated in step 1-1 into the rubber mixture, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com