Shallow-tunnel advance-core-soil extrusion displacement monitoring system and method

A technology for displacement monitoring and shallow tunneling, which is applied in earth-moving drilling, measuring devices, mining devices, etc., can solve the problems of limited effective measurement length of sliding micrometers, difficult to avoid damage to measuring tubes, and high price of measuring tubes. , to achieve the effect of low implementation cost and difficulty, low price and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

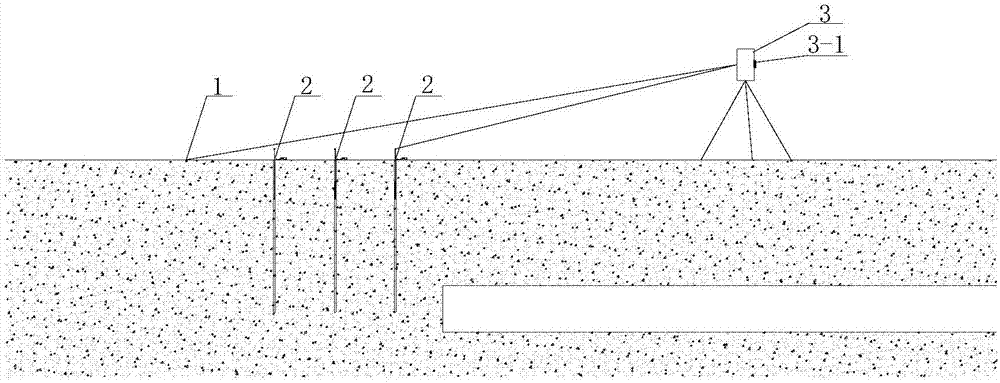

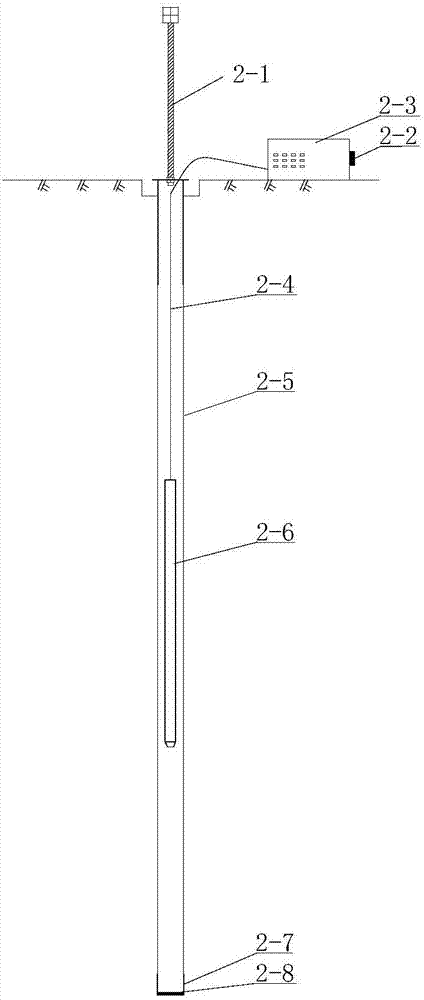

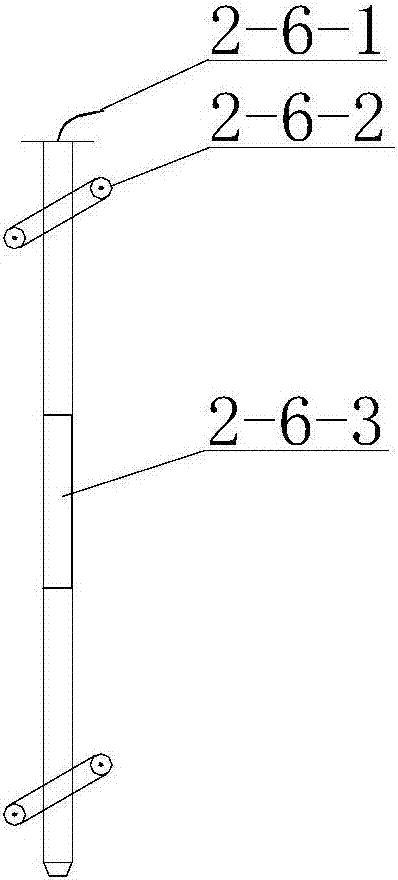

[0040] exist figure 1 , 2 , 3, 4, 5, and 6, the shallow-buried tunnel advanced core soil extrusion displacement monitoring system of the present invention includes a ground measurement system and an extrusion displacement measurement device 2, and the ground monitoring system includes a total station type electronic ranging Instrument 3 and reference point system 1, the reference point system is set in the direction of the tunnel axis, and the reference point system in use must be located in the undisturbed area in front of the tunnel face or in the area where the formation deformation has stabilized behind the tunnel face; The reference point system 1 includes concrete blocks and connecting steel bars, the concrete blocks are embedded in the ground, the connecting steel bars are embedded in the concrete blocks and extend into the ground, and the ground ends of the connecting steel bars are provided with reflective sheets. The data receiving module 3-1 connected on the electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com