Two-way torsion spring pretightening mechanism

A pre-tightening mechanism, two-way torsion spring technology, used in torsion springs, mechanical equipment, springs/shock absorbers, etc., can solve the problems of difficult to achieve precise and consistent pre-tightening force, difficult processing and assembly, complex principle and structure, etc. , to achieve the effect of being conducive to mass production and popularization, low cost and exquisite principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

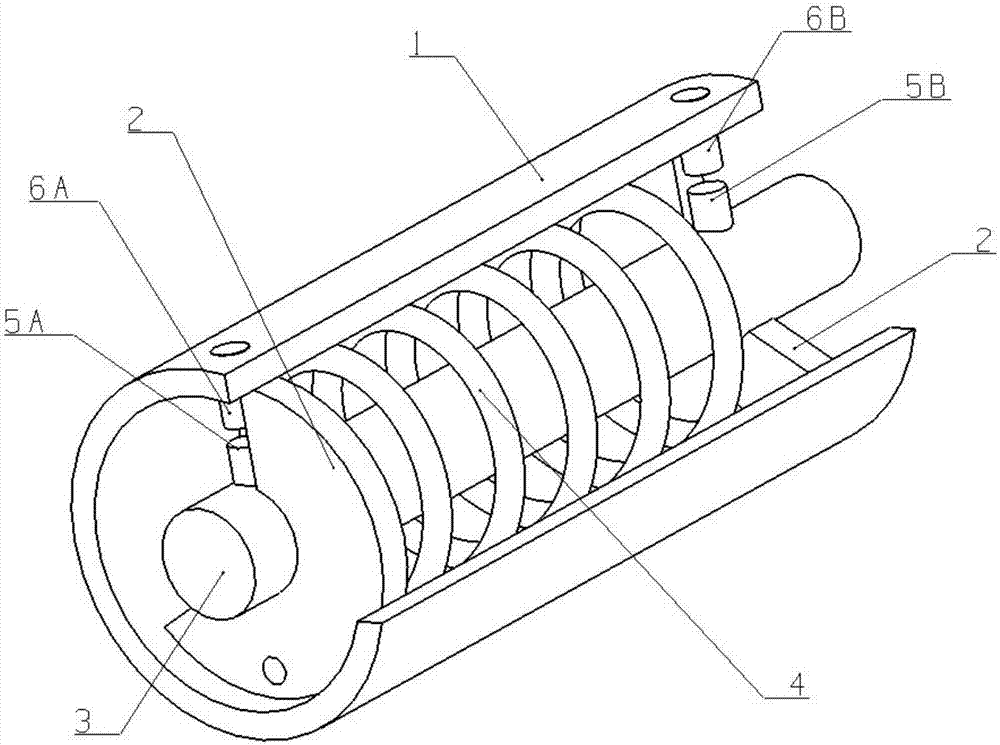

[0036] A two-way torsion spring preload mechanism, see figure 1 The structure includes cylinder 1, crescent plate 1 2A, crescent plate 2 2B, output shaft 3, torsion spring 4, push block 1 5A, push block 2 5B, stop block 1 6A, stop block 2 6B, retaining ring 1 7A, retaining ring two 7B;

[0037] Cylinder 1 is a hollow cylinder with openings at both ends, with an outer diameter of 20mm, a height of 44mm, and an inner diameter of 16mm;

[0038] On the inner side of the cylinder wall of the cylinder 1 close to the openings at both ends of the cylinder 1, there are respectively provided with annular chute, the groove width is 2.2mm, and the groove depth is 0.8mm;

[0039] Crescent plate 1 2A and crescent plate 2 2B are fan-shaped annular structures, with the same external dimensions, outer diameter 17.2mm, inner diameter 6.3mm, thickness 2mm, fan angle 120 degrees, and a through hole with a diameter of 2mm on the fan surface; crescent plate 1 2A, the second crescent plate 2B are ...

Embodiment 2

[0048] A two-way torsion spring preload mechanism, see figure 1 The structure includes cylinder 1, crescent plate 1 2A, crescent plate 2 2B, output shaft 3, torsion spring 4, push block 1 5A, push block 2 5B, stop block 1 6A, stop block 2 6B, retaining ring 1 7A, retaining ring two 7B;

[0049] Cylinder 1 is a hollow cylinder with openings at both ends, with an outer diameter of 35 mm, a height of 50 mm, and an inner diameter of 30 mm;

[0050] On the inner side of the cylinder wall of the cylinder 1 close to the openings at both ends of the cylinder 1, there are respectively ring-shaped sliding grooves with a groove width of 3.2mm and a groove depth of 0.8mm;

[0051] Crescent plate 1 2A and crescent plate 2 2B are fan-shaped annular structures with consistent dimensions, outer diameter 31.2mm, inner diameter 8.3mm, thickness 3mm, fan angle 120 degrees, and a through hole with a diameter of 3mm on the fan surface; crescent plate 1 2A, the second crescent plate 2B are instal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com