Manipulator structure with demountable rack

A technology of manipulator and gear structure, applied in the direction of manipulators, program control manipulators, mechanical equipment, etc., can solve the problems of easy wear, high cost of metal materials, short service life of manipulators, etc., and achieve the effect of ensuring the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

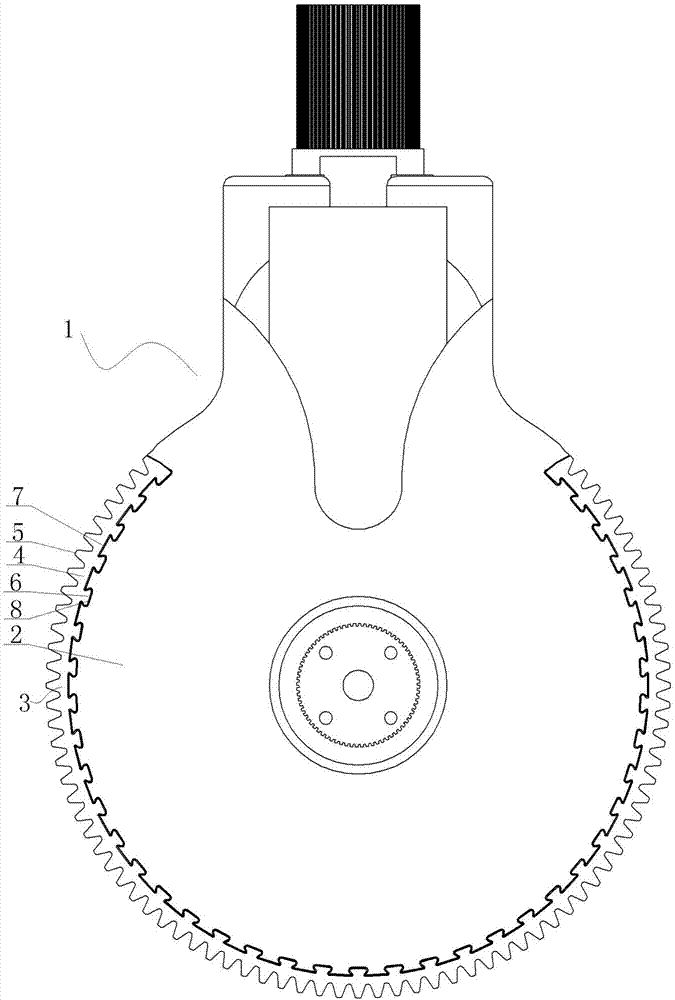

[0036] Specific embodiment one, see figure 1 : The inner peripheral surface of the arc carrier 4 is evenly distributed with inwardly convex embedded protrusions 6, and the embedded protrusions 6 are evenly arranged along the arc direction of the inner peripheral surface of the arc carrier 4, and there are 6 adjacent embedded protrusions There is an interval space 7, and the outer peripheral surface of the gear body 2 is provided with a positioning groove 8 compatible with the embedded protrusion 6, and the embedded protrusion 6 on the rack structure 5 is positioned and embedded in the corresponding positioning groove 8 , There is a tight fit between the embedding protrusion 6 and the positioning groove 8 .

specific Embodiment 2

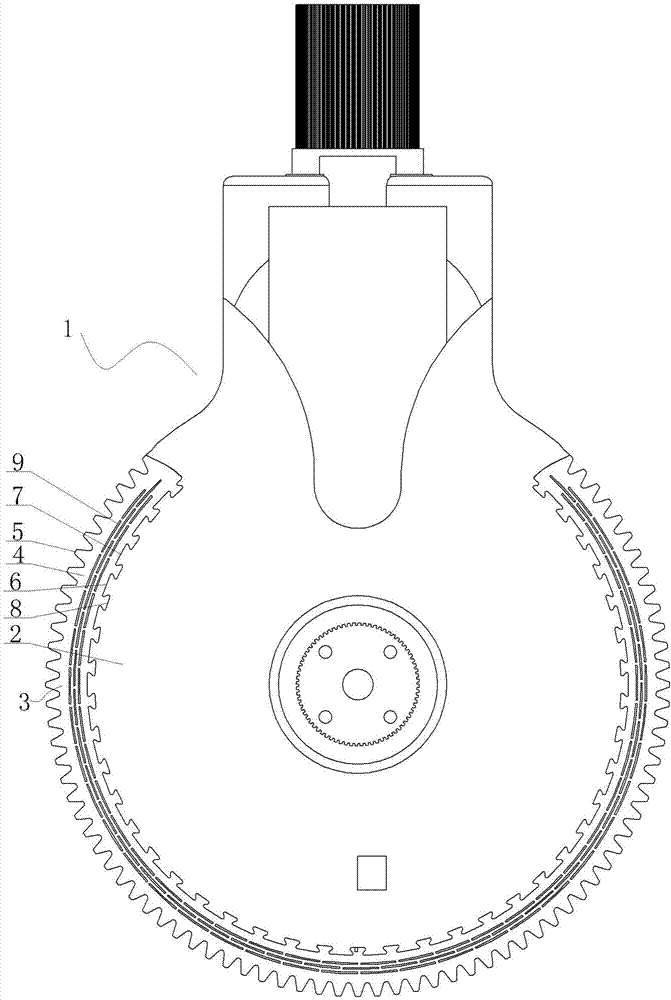

[0037] Specific embodiment two, see figure 2 : The inner peripheral surface of the arc carrier 4 is evenly distributed with inwardly convex embedded protrusions 6, and the embedded protrusions 6 are evenly arranged along the arc direction of the inner peripheral surface of the arc carrier 4, and there are 6 adjacent embedded protrusions There is an interval space 7, and the outer peripheral surface of the gear body 2 is provided with a positioning groove 8 compatible with the embedded protrusion 6, and the embedded protrusion 6 on the rack structure 5 is positioned and embedded in the corresponding positioning groove 8 In the radial thickness direction of the arc carrier 4 or the intermediate base body, a plurality of discontinuous first air hole structures 9 are arranged along the circumferential direction.

specific Embodiment 3

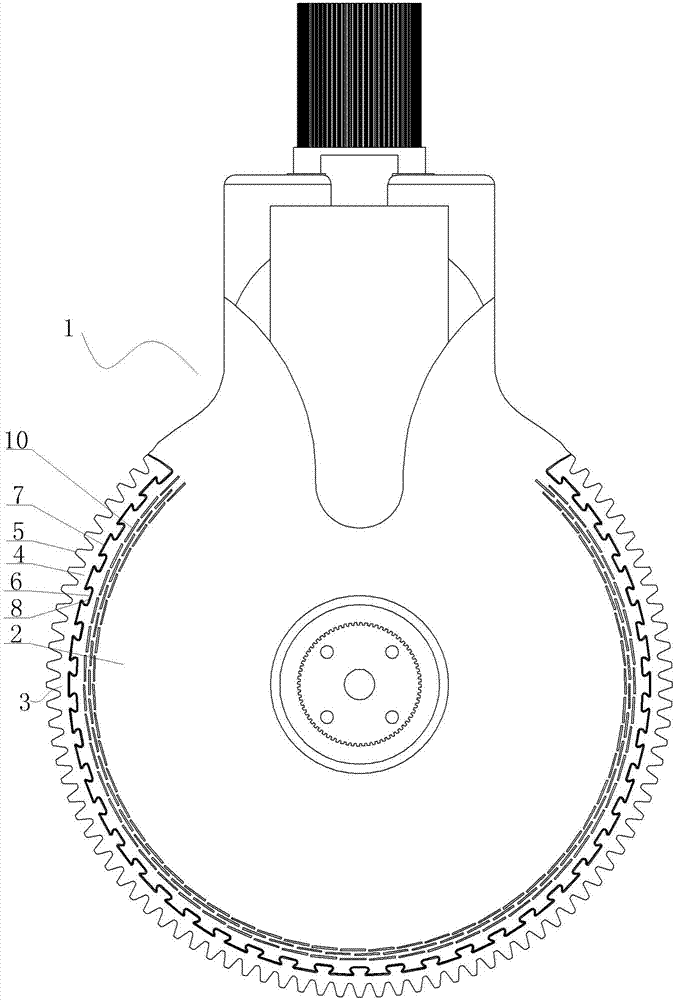

[0038] Specific embodiment three, see image 3 : The inner peripheral surface of the arc carrier 4 is evenly distributed with inwardly convex embedded protrusions 6, and the embedded protrusions 6 are evenly arranged along the arc direction of the inner peripheral surface of the arc carrier 4, and there are 6 adjacent embedded protrusions There is an interval space 7, and the outer peripheral surface of the gear body 2 is provided with a positioning groove 8 compatible with the embedded protrusion 6, and the embedded protrusion 6 on the rack structure 5 is positioned and embedded in the corresponding positioning groove 8 The inner ring part of the positioning groove 8 of the rack body 2 is provided with a plurality of mutually discontinuous second air hole structures 10 along the ring direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com