Electrical equipment winding length wireless detection device and detection method

A technology of electrical equipment and wireless detection, which is applied in the direction of measuring devices, mechanical measuring devices, and mechanical devices, etc., can solve the problems of large floor area, numerous equipment, and infeasible cable transmission, so as to avoid slipping and reduce slipping The effect of probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

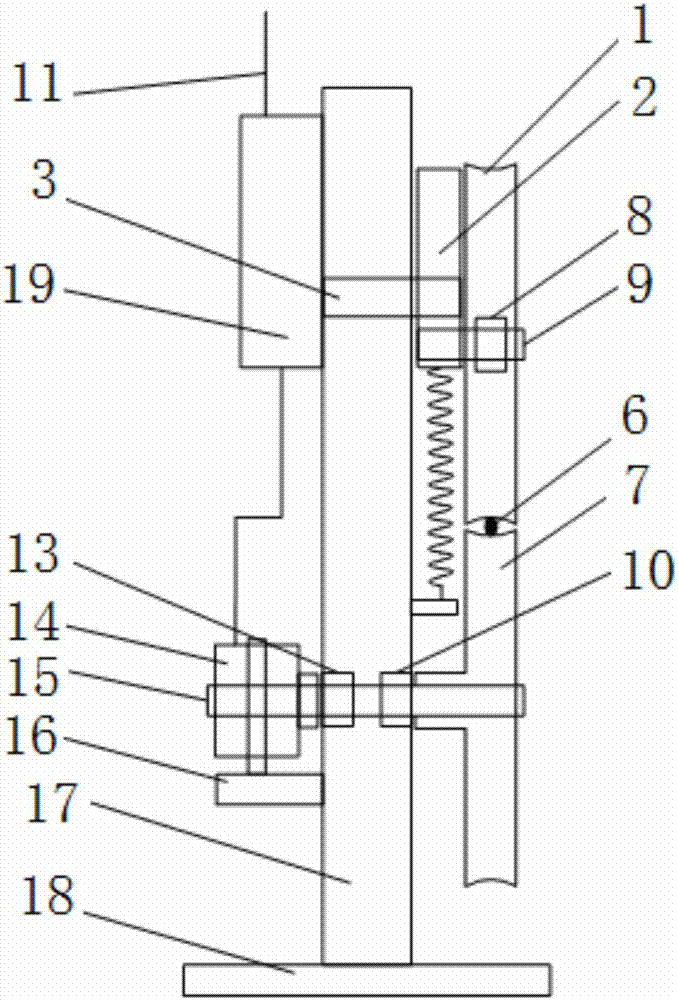

[0056] In this embodiment, the detection device is a photoelectric encoder 14 .

[0057] Such as figure 2 As shown, the photoelectric encoder 14 is arranged on the side of the main equipment support 17 away from the detection guide wheel 7, and the hollow shaft of the photoelectric encoder 14 is coaxially arranged with the detection guide wheel 7 and follows the detection guide wheel 7 Rotate, the photoelectric encoder bracket 16 is arranged on the main equipment bracket 17, and the photoelectric encoder 14 is installed on the photoelectric encoder bracket 16.

[0058] In this embodiment, the photoelectric encoder adopts Rip Avago's ZKP3808 photoelectric encoder.

[0059] The working principle of this embodiment is:

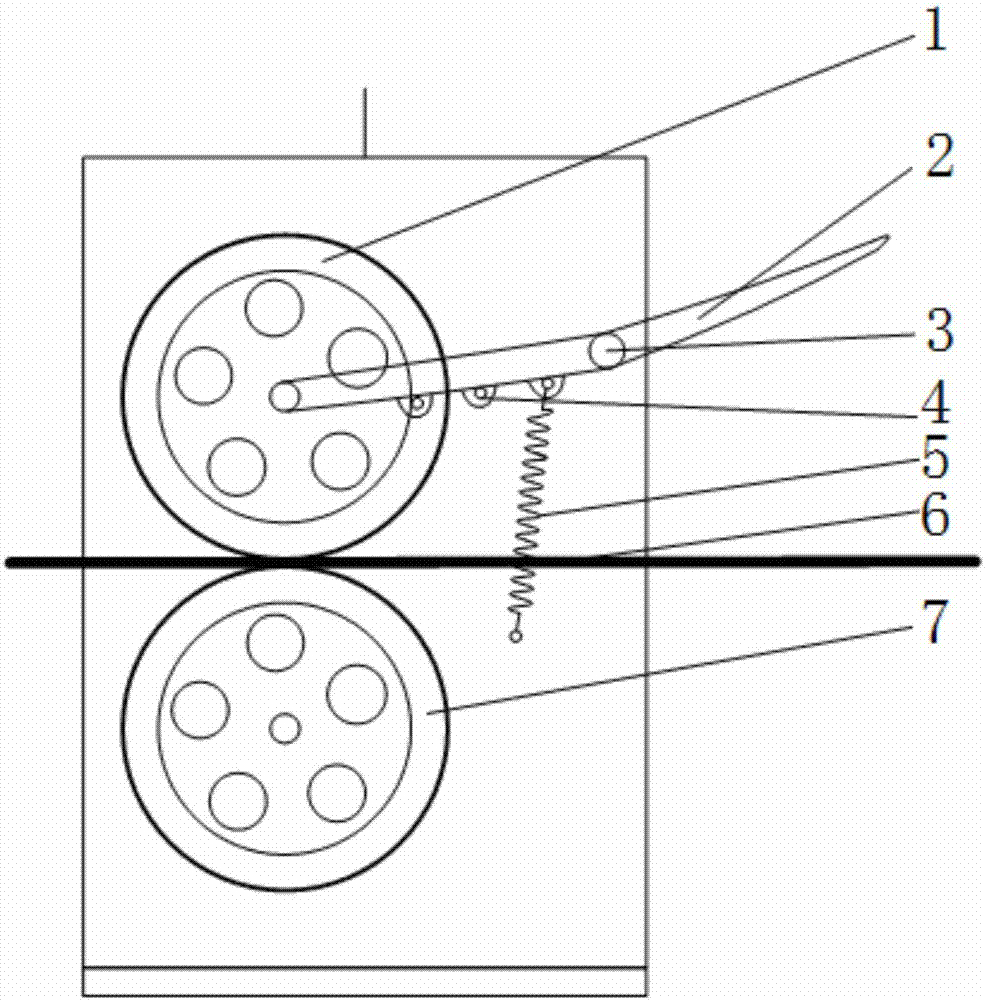

[0060] When the mechanism is working, press down the pinch wheel lever 2 to lift the pinch wheel 1, place the measured enameled wire 6 between the pinch wheel 1 and the detection guide wheel 7, and then put down the pinch wheel lever 2 to make the pinch wheel ...

Embodiment 2

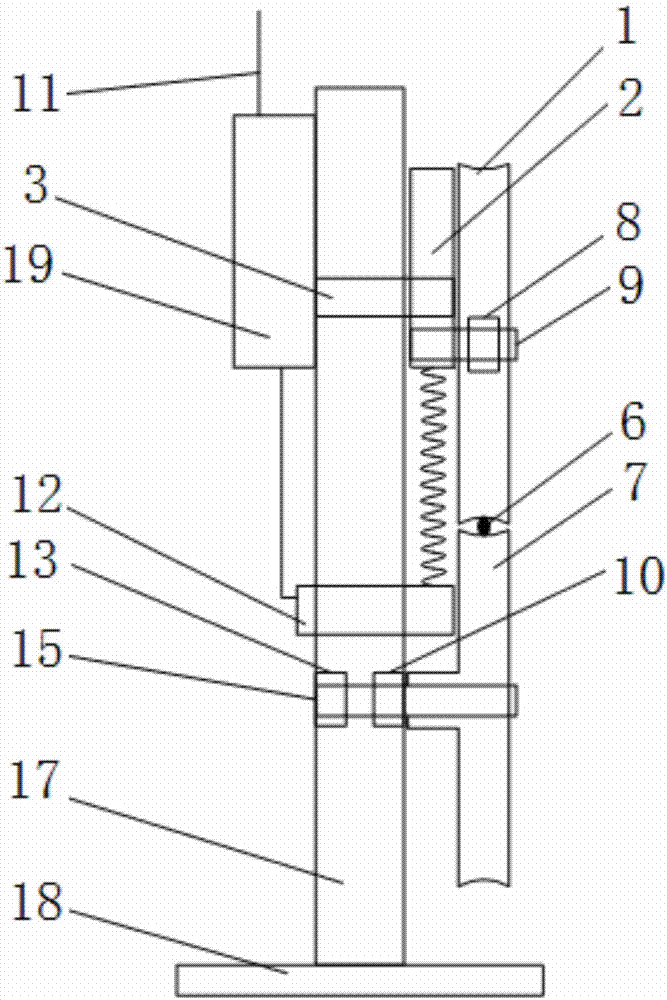

[0066] In this embodiment, the detection device is a proximity switch 12 .

[0067] Such as image 3 As shown, the proximity switch 12 is fixedly mounted on the main equipment bracket 17, and a round hole for triggering the proximity switch 12 is provided on the detection guide wheel 7. When the position facing the front of the proximity switch 12 is a round hole, a high level is output. When the proximity switch 12 is blocked by the detection guide wheel 7, it outputs a low level. In this embodiment, five circular holes are provided on the detection guide wheel 7 .

[0068] In this embodiment, the model of the proximity switch 12 is PR08-1.5DN, and the manufacturer is Autonics.

[0069] The working principle of this embodiment is:

[0070] When the mechanism is working, press the compression lever 2 to lift the compression wheel 1, place the measured enameled wire 6 between the compression wheel 1 and the detection guide wheel 7, and then lower the compression wheel lever ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com