Embedded dynamic pressure tester

A dynamic pressure and tester technology, applied in the direction of measuring blasting force, etc., can solve the problems that the dynamic pressure test system cannot be embedded, the dynamic response frequency range is narrow, the cable connection and layout are cumbersome, etc., and the structure is simple and reliable, and the dynamic response frequency is wide. , the effect of high signal-to-noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to illustrate the technical scheme and technical purpose of the present invention, the present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

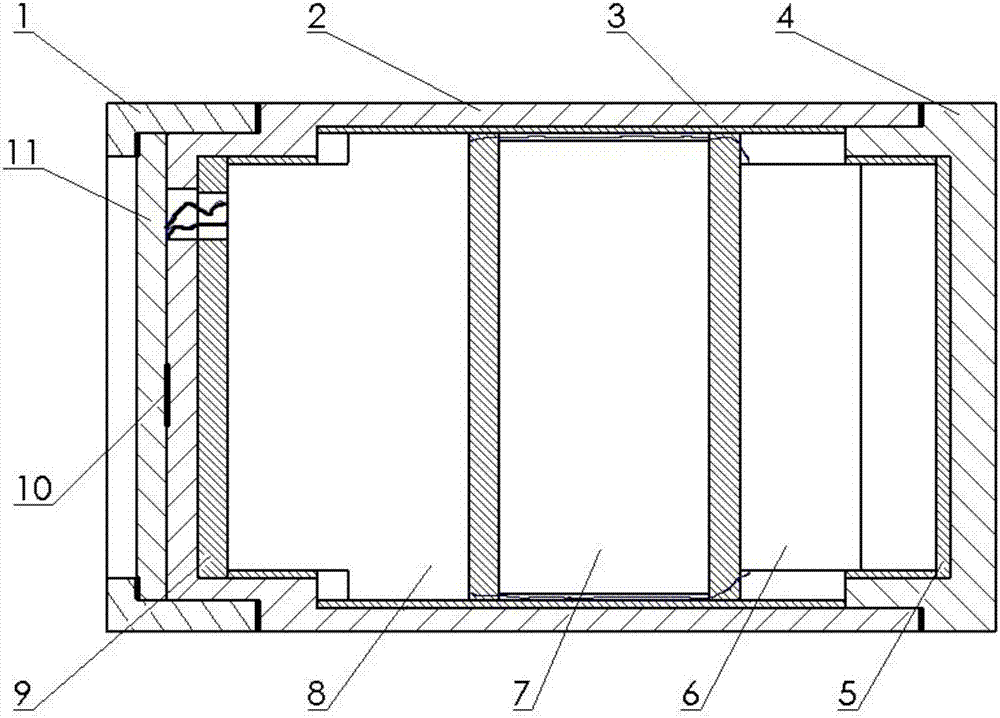

[0014] An embedded dynamic pressure tester, comprising a front cover 1, a casing 2, a rear cover 4, a battery 7, a main circuit board 8, a PVDF film 10, and a gland 11;

[0015] The front end cover 1 and the rear end cover 4 are fixedly connected to the front and rear ends of the casing 2 respectively; the casing is a cavity structure with an open rear end; the gland 11 is located between the front end cover 1 and the casing 2, and The PVDF film 10 is located between the rear end surface of the gland 11 and the front surface of the housing 2, and the gland 11 and the housing 2 are bonded to the PVDF film 10; the PVDF film 10 is used to test the shock wave transmitted from the gland 11 and reflected back from the front surface of the housing 2 of reflect...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap