Dispersion test equipment suitable for low-permeability soil

A test equipment and low-permeability technology, applied in the field of environmental geotechnical engineering, can solve the problems of easy fracture of soil columns, high labor costs, and small water output, and achieve the effects of avoiding sidewall penetration, shortening test time, and maintaining stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

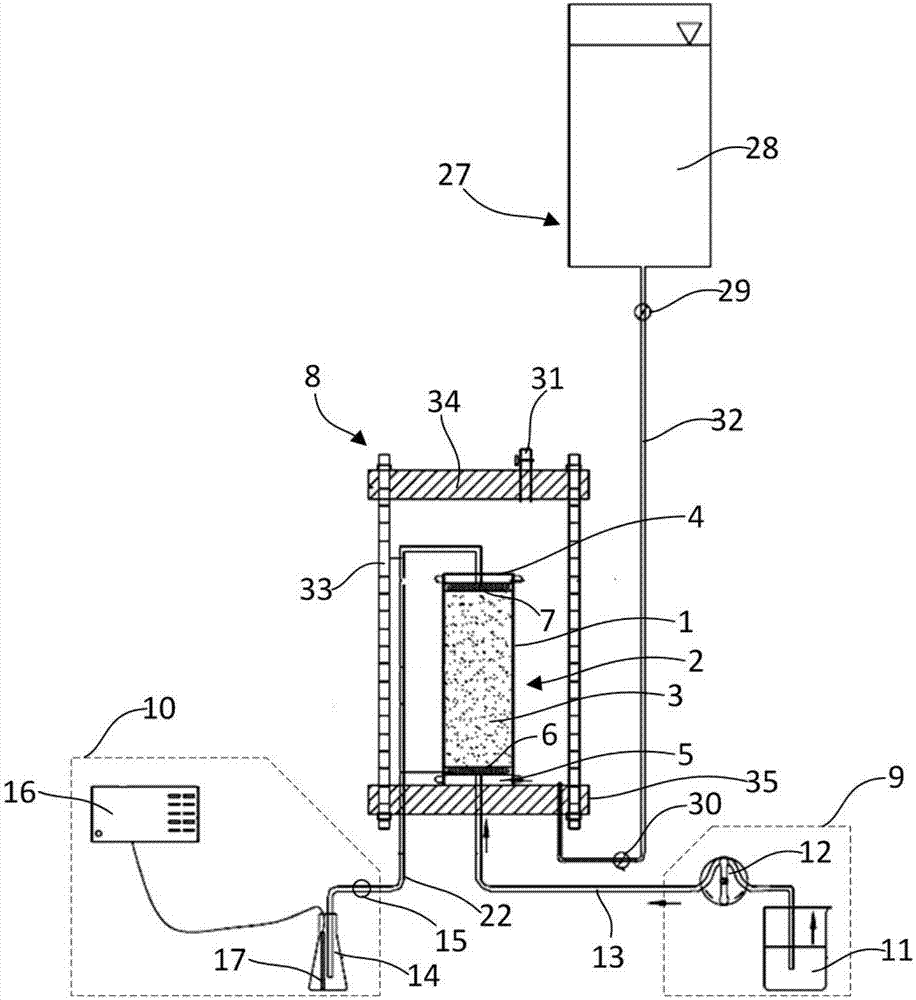

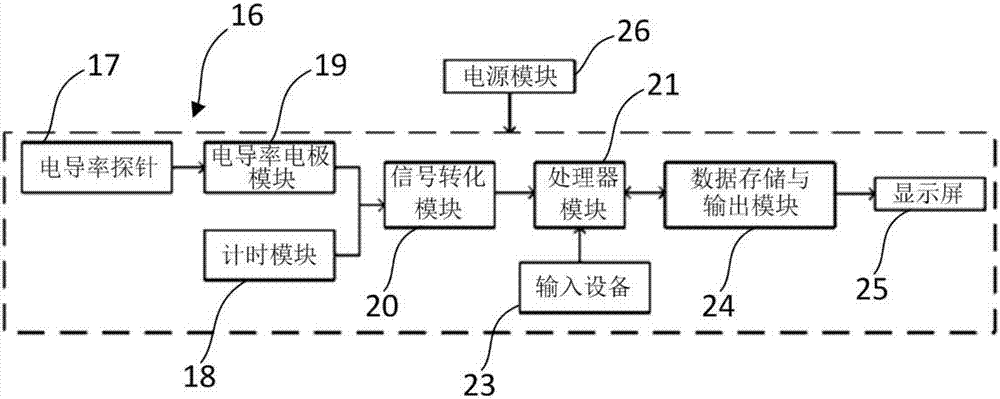

[0019] Example: such as figure 1 As shown, the present embodiment specifically relates to a dispersion test device suitable for low-permeability soil, the dispersion test device includes a hydraulic chamber 8 and a permeameter chamber 2 for containing the test soil column 3; The pressure component 27 is connected; the osmometer chamber 2 is arranged inside the water pressure chamber 8; the osmometer chamber 2 includes the instrument chamber top plate 4, the instrument cavity bottom plate 5 and the cylindrical flexible side wall 1, the instrument cavity top plate 4 and the instrument cavity The chassis 5 forms a sealed connection with both ends of the flexible side wall 1 respectively; the chassis 5 of the instrument cavity is connected with a tracer injection component 9 , and the top plate 4 of the instrument cavity is connected with a tracer collection and detection component 10 .

[0020] Such as figure 1 As shown, in this embodiment, the flexible side wall 1 is made of a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com