Detection device for LED light bar

A technology for LED strips and testing equipment, which is used in lamp testing, optical testing for flaws/defects, etc., and can solve problems such as low efficiency and excessive labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

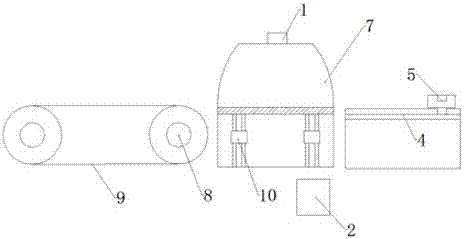

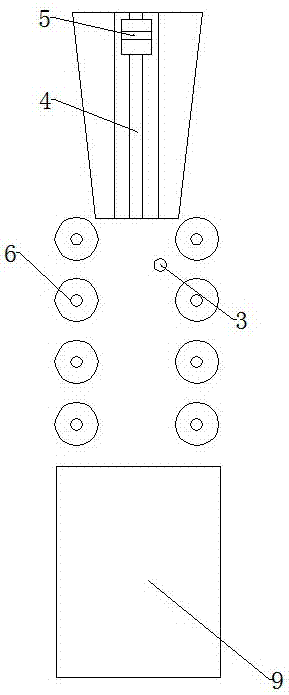

[0018] LED light strip testing equipment, including: a suction moving assembly that sucks up the LED light strip and transmits it to the detection entrance, an optical detector 1 that detects the LED light strip, and a delivery roller 6 that is set at the lower end of the optical detector 1 and limits the LED light strip Components, the electrical tester 2 located at the lower end of the limit transmission component, the electrical probe 3 connected to the electrical tester 2 and in contact with the LED light bar, and the conveyor belt 9 assembly that receives the tested LED light bar. It should be noted that the optical detector 1 used in the present invention is not limited, and the general optical detector 1 can be used. As an embodiment, the optical detector 1 can be selected from Beijing Quanou Optical Detector Co., Ltd. Universal de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com