Structure and method for detecting post-grouting sleeve-type bar splice by external vibration test method

A vibration test, sleeve-type technology, applied in the detection field, can solve problems such as the density of grouted concrete failing to meet the specified requirements, potential safety hazards of prefabricated buildings, and affecting the quality of on-site connection nodes of prefabricated components, etc., to achieve good engineering practicality Foreground and detection are less difficult to achieve, and the results are intuitive and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and implementation steps.

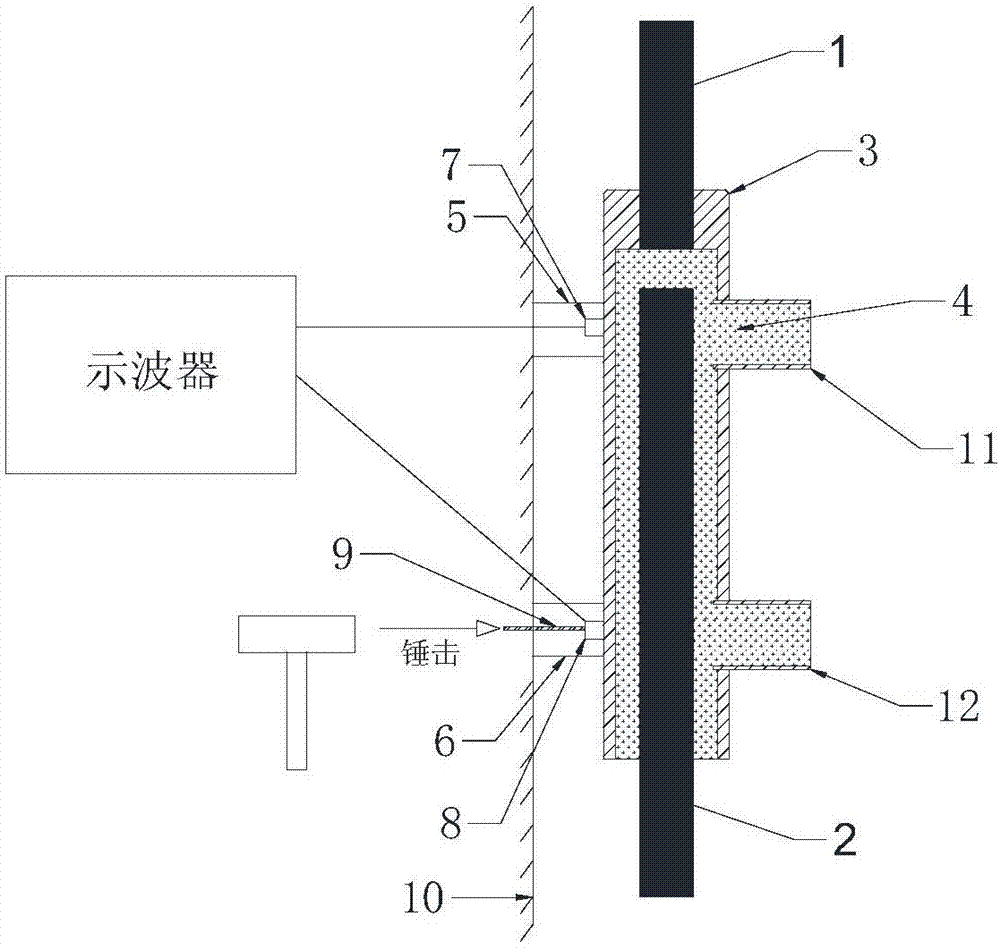

[0022] like figure 1 Shown is a schematic diagram of the structure of the grouted sleeve-type steel bar joint after the vibration test method. This detection method is mainly aimed at the situation that the grouting and overflow channel of the steel sleeve is bent (grouting can be performed through an exposed hose), and the overflow channel 11 and the grouting channel 12 are far away from the surface of the grouting operation wall.

[0023] The structure of the grouted sleeve-type steel bar joint after detection by the external vibration test method is as follows:

[0024] The post-grouting sleeve type steel bar joint is located in the wall body 10, and the joint structure includes an upper component embedded steel bar 1, a lower component embedded steel bar 2, a grouting sleeve 3 and a detection device. The detection device includes an accel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com