Touch screen and method for manufacturing same

A technology of touch screen and contact pad, which is applied in the direction of instrument, electrical digital data processing, input/output process of data processing, etc., and can solve problems such as poor connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

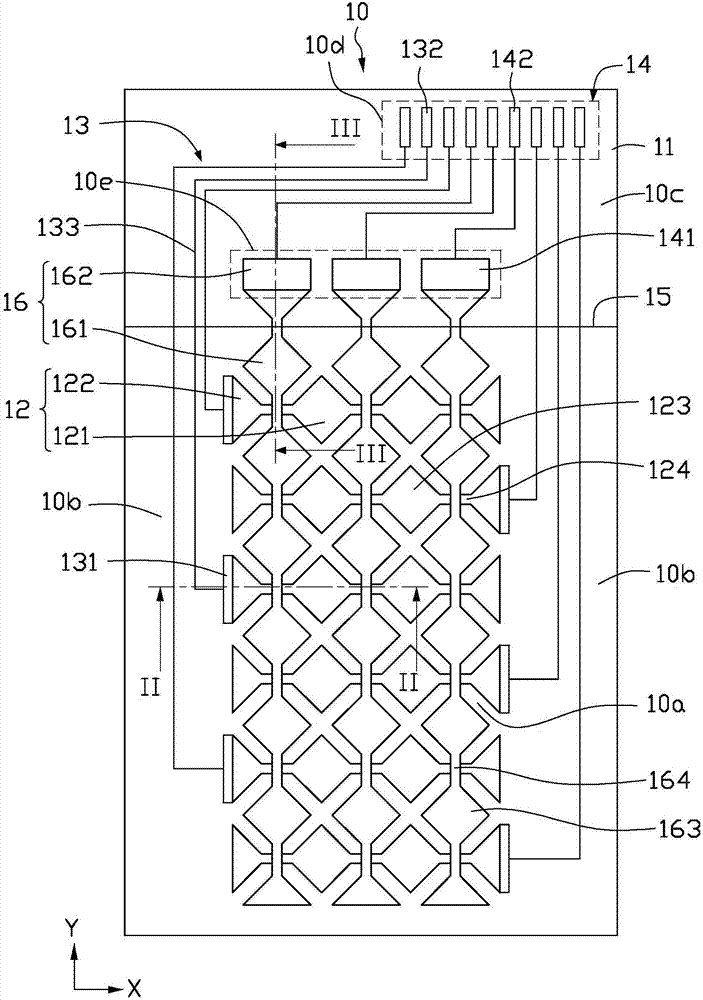

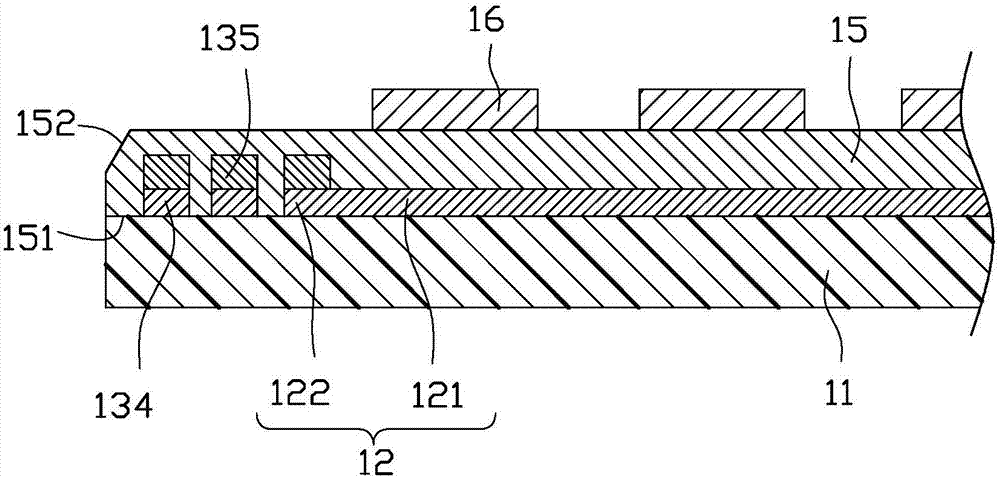

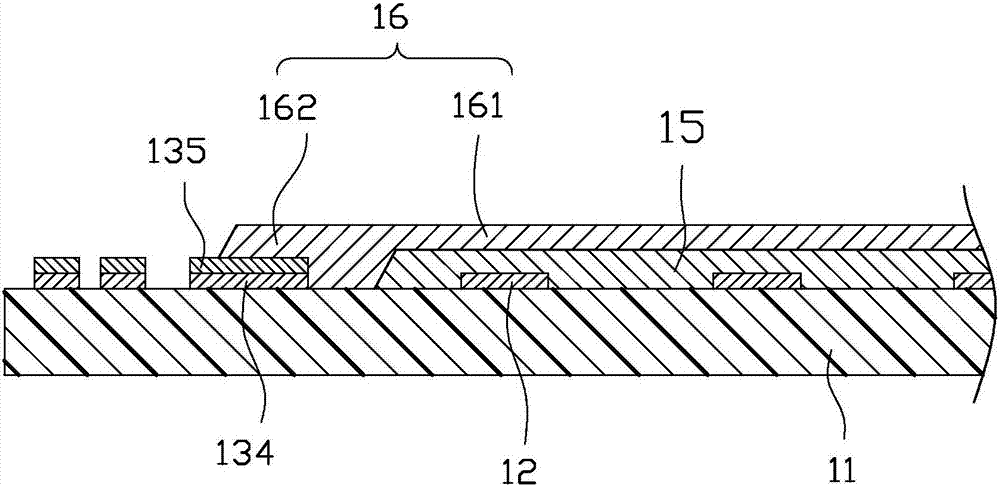

[0065] see figure 1 , figure 2 and image 3 , figure 1 is a schematic plan view of the touch screen 10 according to the first embodiment of the present invention, figure 2 yes figure 1 A schematic sectional view along line II-II, image 3 yes figure 1 Schematic cross-section along line III-III. The touch screen 10 includes a substrate 11 , a first electrode 12 , a first peripheral wiring 13 , a second peripheral wiring 14 , an insulating layer 15 , and a second electrode 16 .

[0066] The touch screen 10 is further divided into a touch area 10a, a first peripheral area 10b located on a first side of the touch area 10a, a second side of the touch area 10a and adjacent to the first peripheral area 10b The second peripheral region 10c. In this embodiment, the number of the first peripheral area 10b is two, the two first peripheral areas 10b are located on opposite sides of the touch area 10a, and the second peripheral area 10c is connected to the touch The region 10a i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap