An isolating switch assembly system

A technology of isolating switch and assembly system, applied in electrical switches, electrical components, circuits, etc., can solve the problems of long assembly time, poor accuracy, low efficiency, etc., to improve tightening efficiency, improve press-fitting efficiency, and reduce worker labor. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

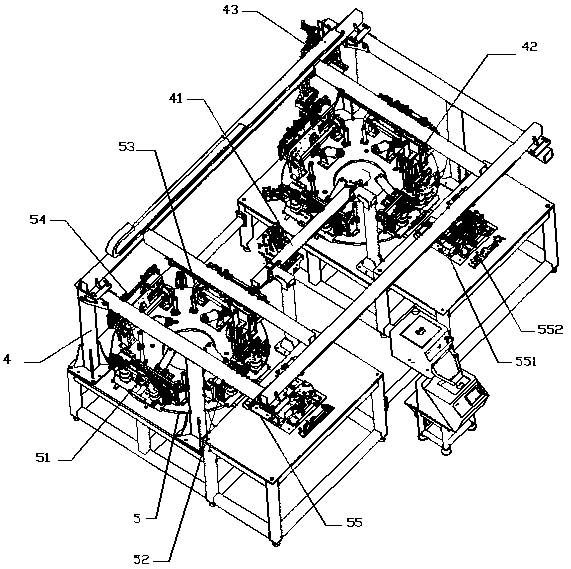

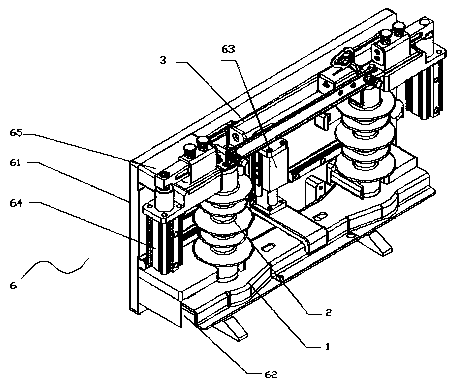

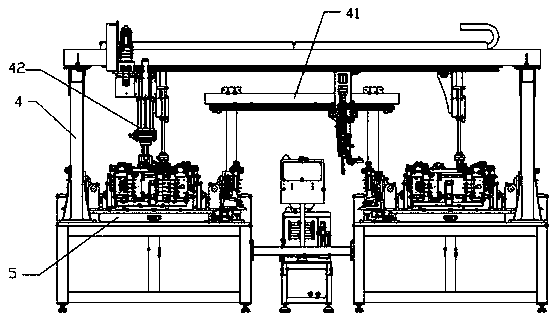

[0021] Such as Figure 1 to Figure 3 An isolating switch assembly system is shown. The isolating switch includes a base plate 1, an insulator 2 and a conductive seat 3; the conductive base 3 is installed on one end of the insulator through a connecting frame, and the other end of the insulator 2 is installed on the base plate 1; including a support frame 4 And the turntable 5, the turntable 5 has a pair and is respectively arranged on the supporting frame 4.

[0022] The turntable 5 is provided with a connecting frame positioning station 51, a conductive seat press fit station 52, a conductive seat tightening station 53 and an isolating switch conversion station 54; The seat tightens the first mobile frame 41 between the stations 53.

[0023] The outer side of the conduct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com