Wiring method of wiring terminal

A terminal and wiring method technology, applied in the direction of connection, line/collector parts, electrical components, etc., can solve the problems of waste of resources, corrosion of paint film, poor ductility and hardness of aluminum wire, etc., and reduce gas and dust Emissions, avoiding environmental damage and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0035] A terminal wiring method in this embodiment includes the following steps:

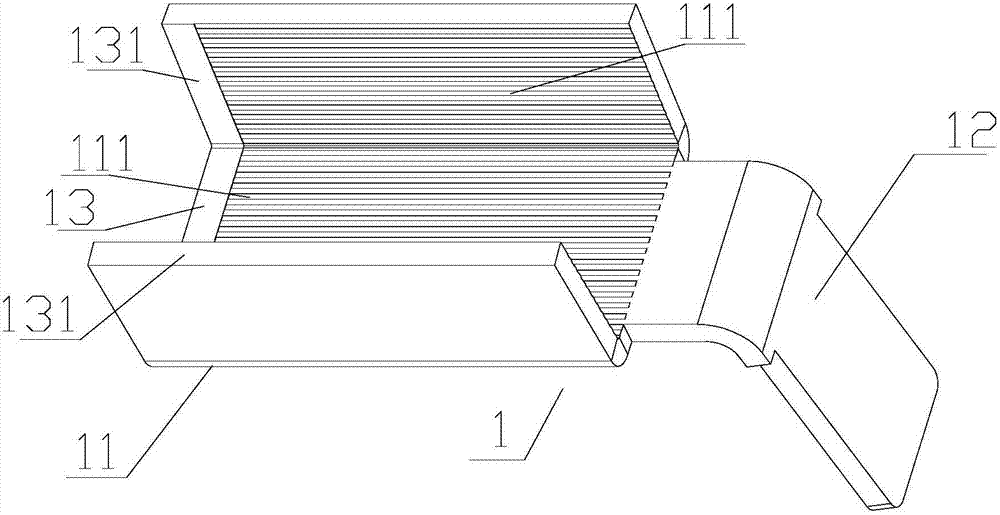

[0036] SO, set up a plurality of paint guide grooves 111 on the inner surface and the bottom surface of the crimping fixing groove 13;

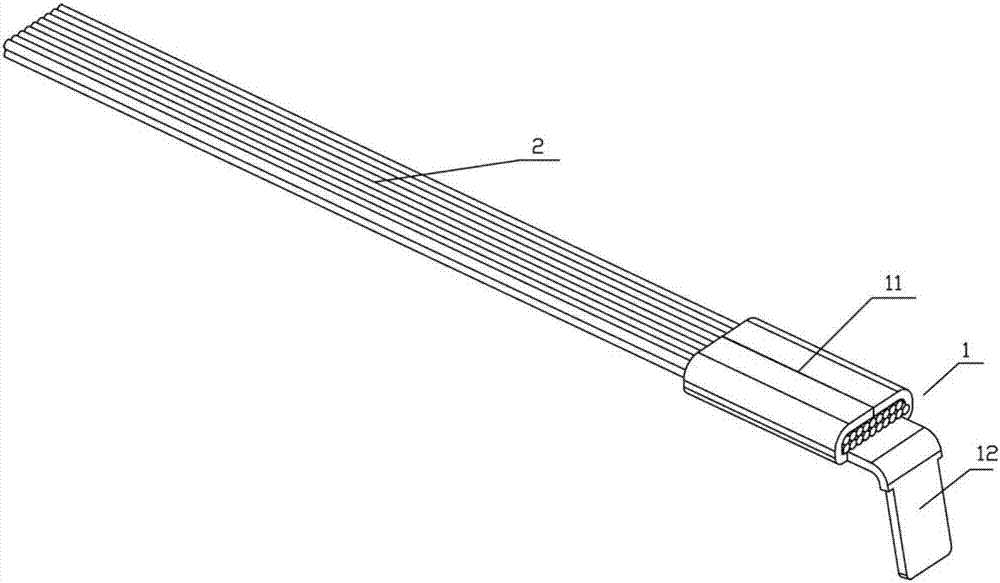

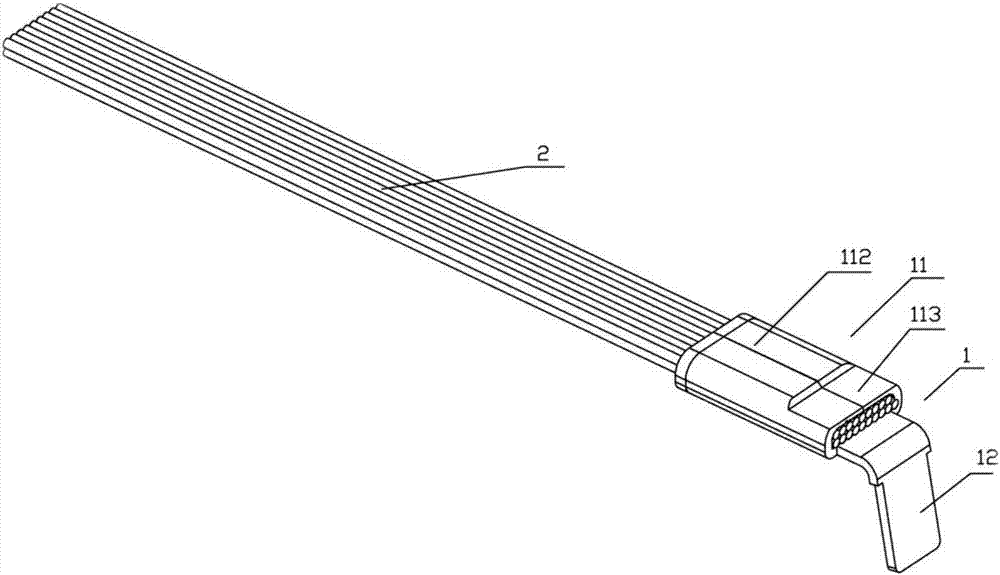

[0037] S1, put the outlet end of enameled wire 2 into figure 1 In the crimping fixing groove 13 of the unformed terminal 1, the side wall 131 of the crimping fixing groove 13 is extruded at least once at room temperature by terminal riveting equipment, so that the enameled wire is fixed on the connecting terminal 1, and the enameled wire The fastening force between 2 and the terminal 1 is greater than or equal to 10N, so as to ensure that the enameled wire 2 is fixedly connected to the terminal 1; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com