Gyromagnetic radial tension-compression excited piezoelectric generator

A generator and piezoelectric technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc. Limited space and other issues, to achieve the effect of simple structure and manufacturing process, controllable range of compressive stress, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

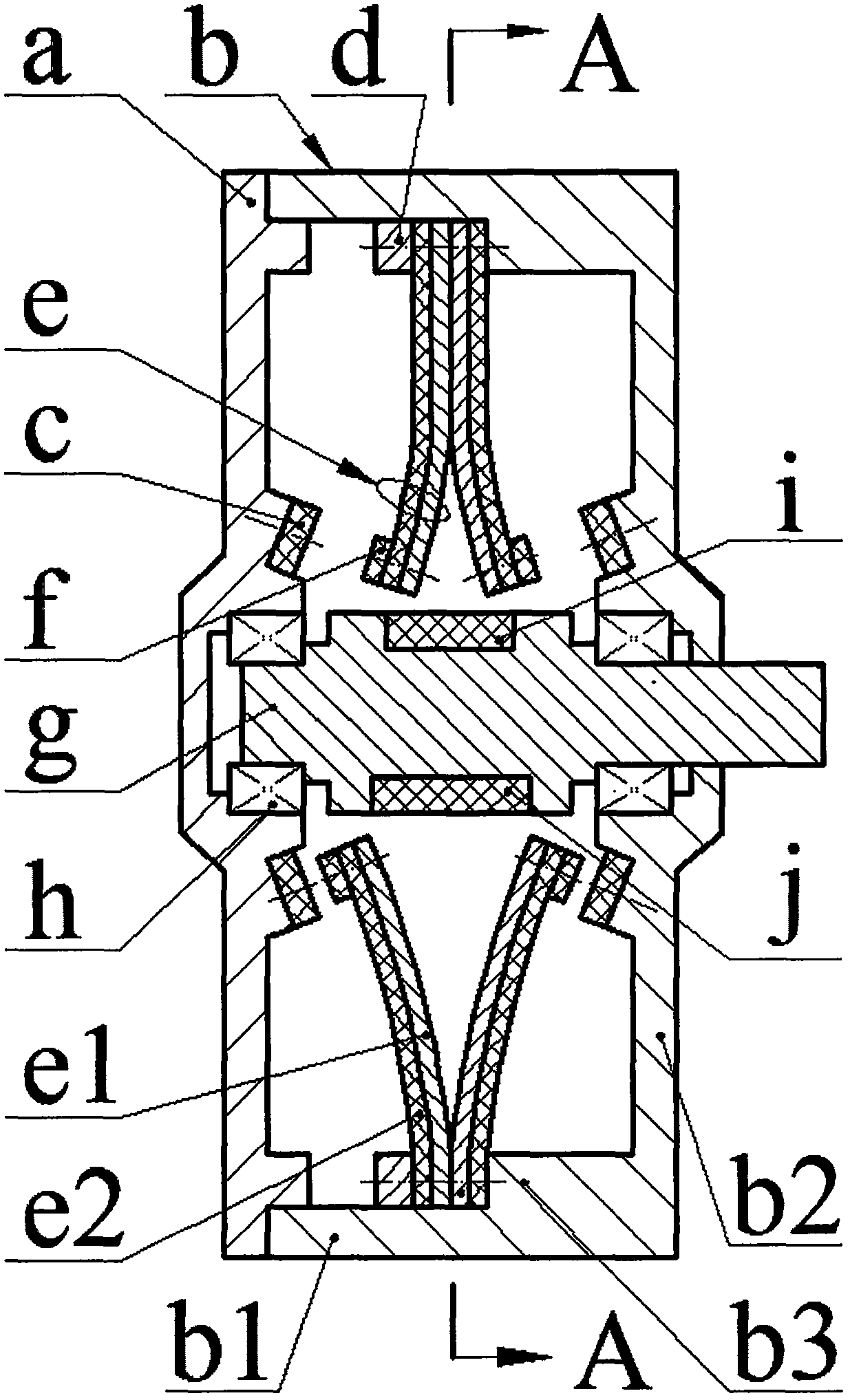

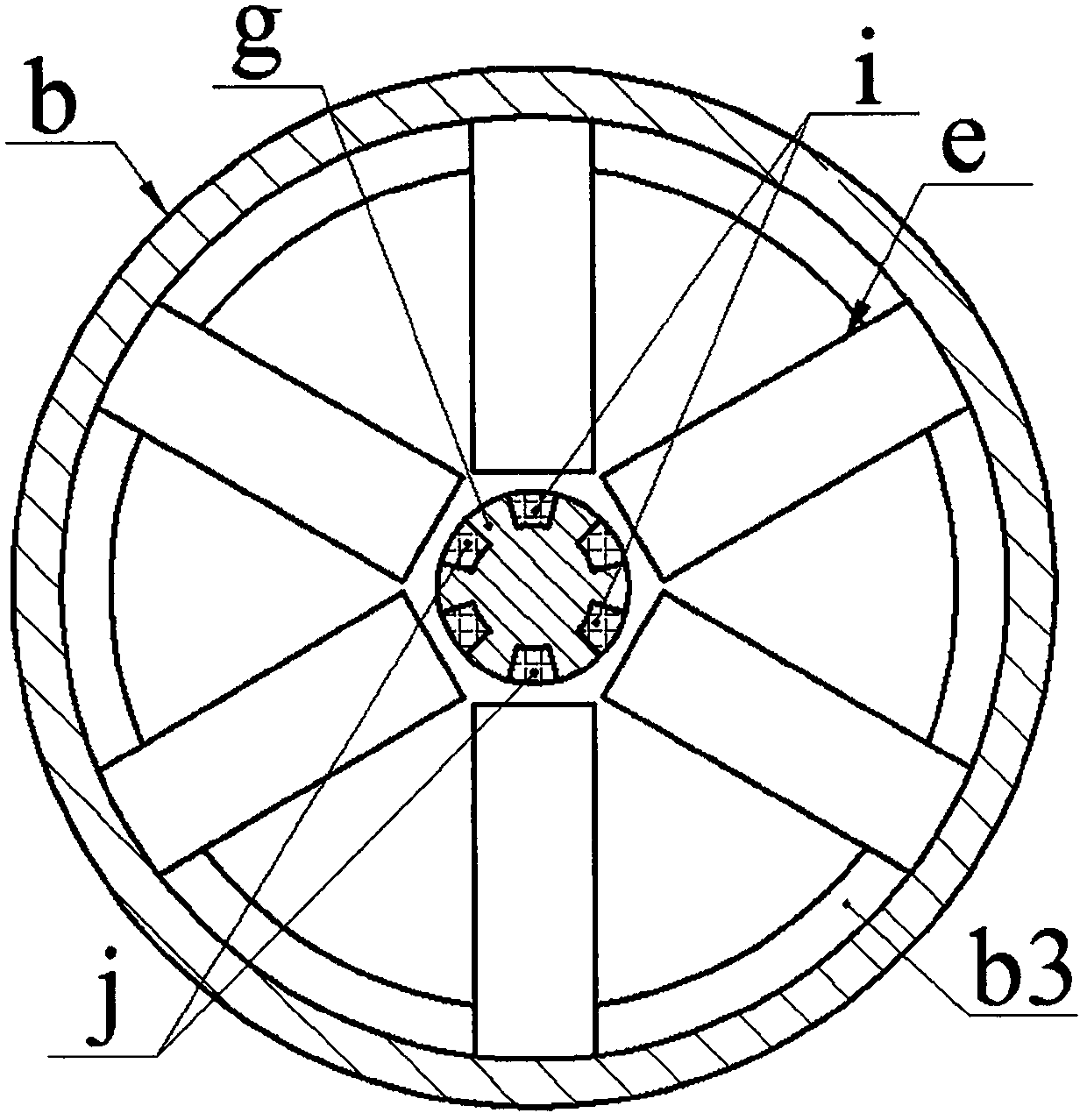

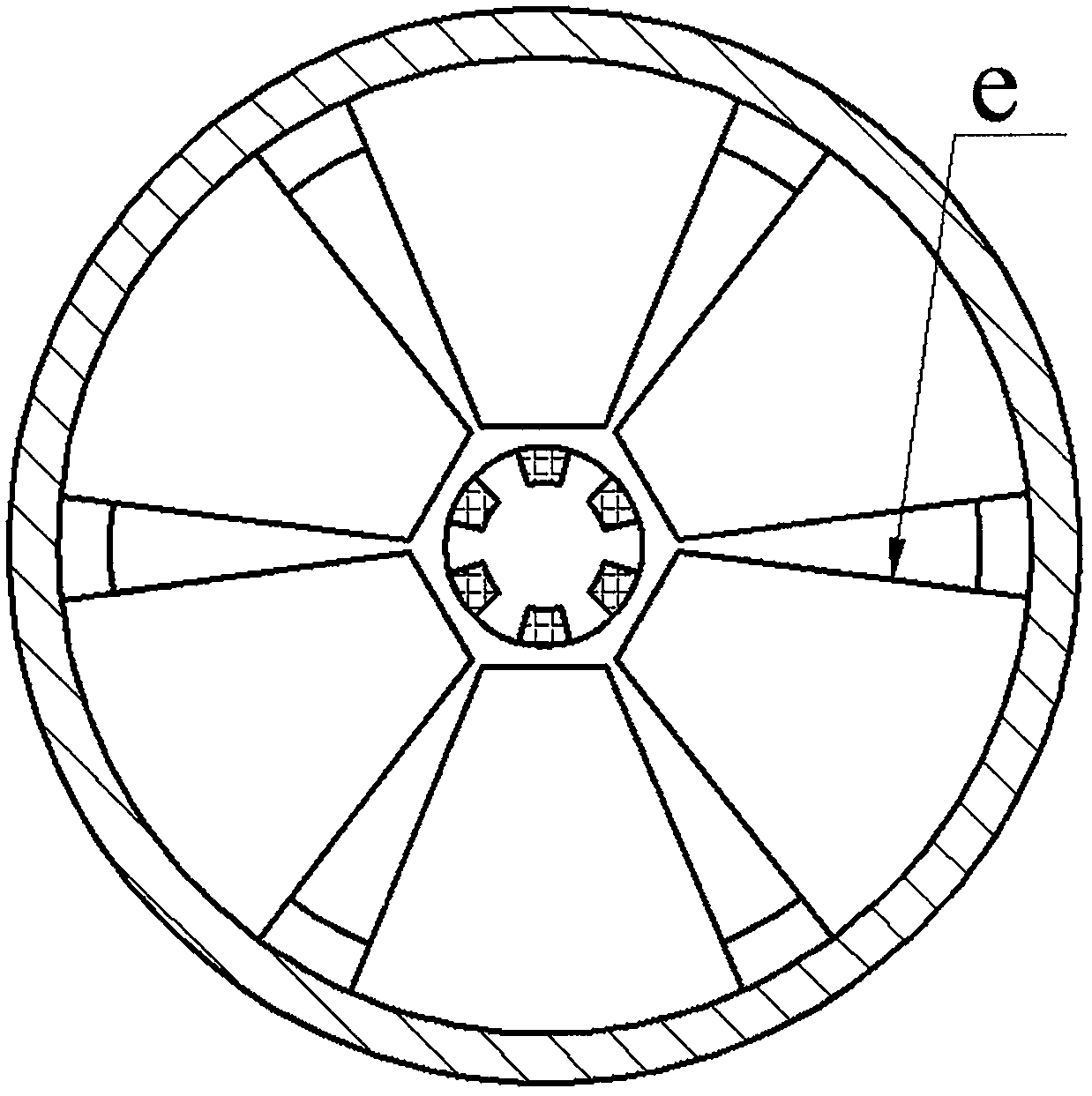

[0010] The end cover a is installed on the end of the cylinder wall b1 of the housing b through screws, and the limit magnet c is installed on the end cover a and the bottom wall b2 of the housing through screws; Two groups of transducers e, the transducer e is formed by bonding the substrate e1 and the piezoelectric sheet e2, the two groups of transducers e are installed symmetrically and the substrates e1 are in contact with each other; the piezoelectric sheet e2 at the free end of the transducer e One side is installed with the excited magnet f through the screw, the same-sex magnetic poles of the excited magnet f and the adjacent limit magnet c are installed oppositely, the same-sex magnetic poles of the two sets of excited magnets f are installed oppositely, and the repulsive force between them makes the transducer e Bending deformation occurs; the left and right ends of the main shaft g are respectively installed on the end cover a and the bottom wall b2 of the housing th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com