High starting torque induction motor for oil field

A technology of induction motor and starting torque, applied in the direction of electrical components, electromechanical devices, magnetic circuit shape/style/structure, etc., to achieve the effects of simple structure, reduced manufacturing cost, and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

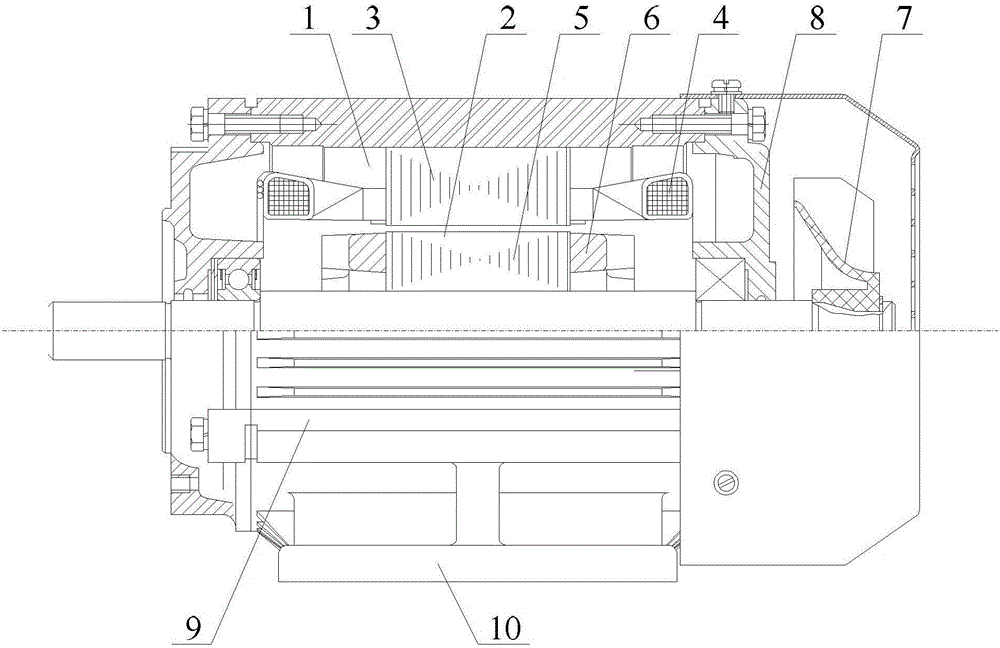

[0016] Combine below figure 1 For illustration, the high starting torque induction motor used in the oilfield described in this embodiment, the structure composition of the high starting torque high efficiency induction motor is consistent with the normal cage induction motor as follows: figure 1 , is mainly divided into two parts, namely stator 1 and rotor 2. The stator mainly includes stator core 3 and stator winding 4 embedded in the stator core. The rotor part mainly includes rotor core 5 connected by a rotating shaft and end rings, Cage bars 6 and fans 7 for ventilation and cooling. In addition, there are front and rear end covers 8, a casing 9 and a frame 10 outside the stator to support and protect the motor structure.

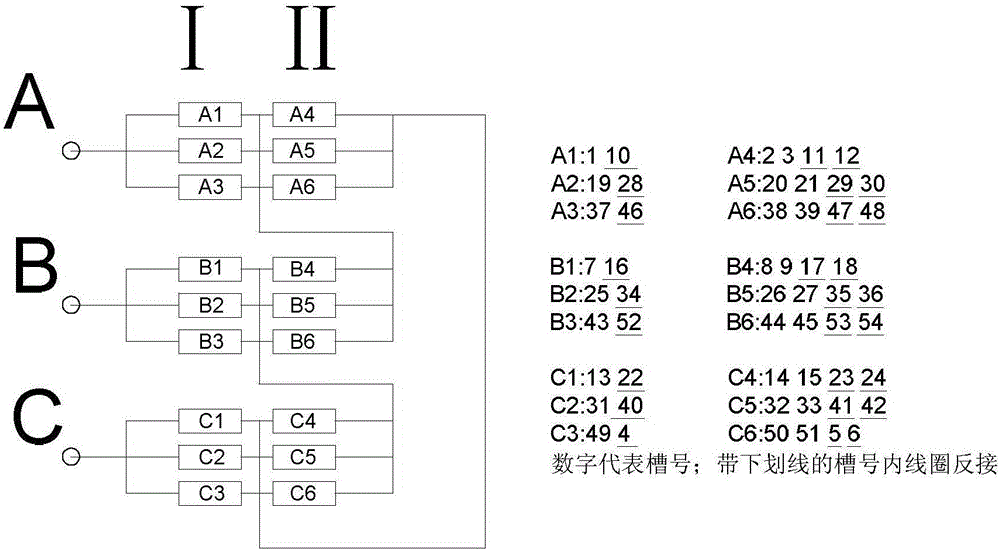

[0017] This implementation mode is a transformation of the existing Y2 series induction motors, so as to realize the function of high starting torque and adapt to the oil field working environment under the condition that the machine frame size remains...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com