A Gradual Excited Piezoelectric Fluid Generator

A generator and fluid technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc. The effect of strong fluid adaptability, improved power generation capacity, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

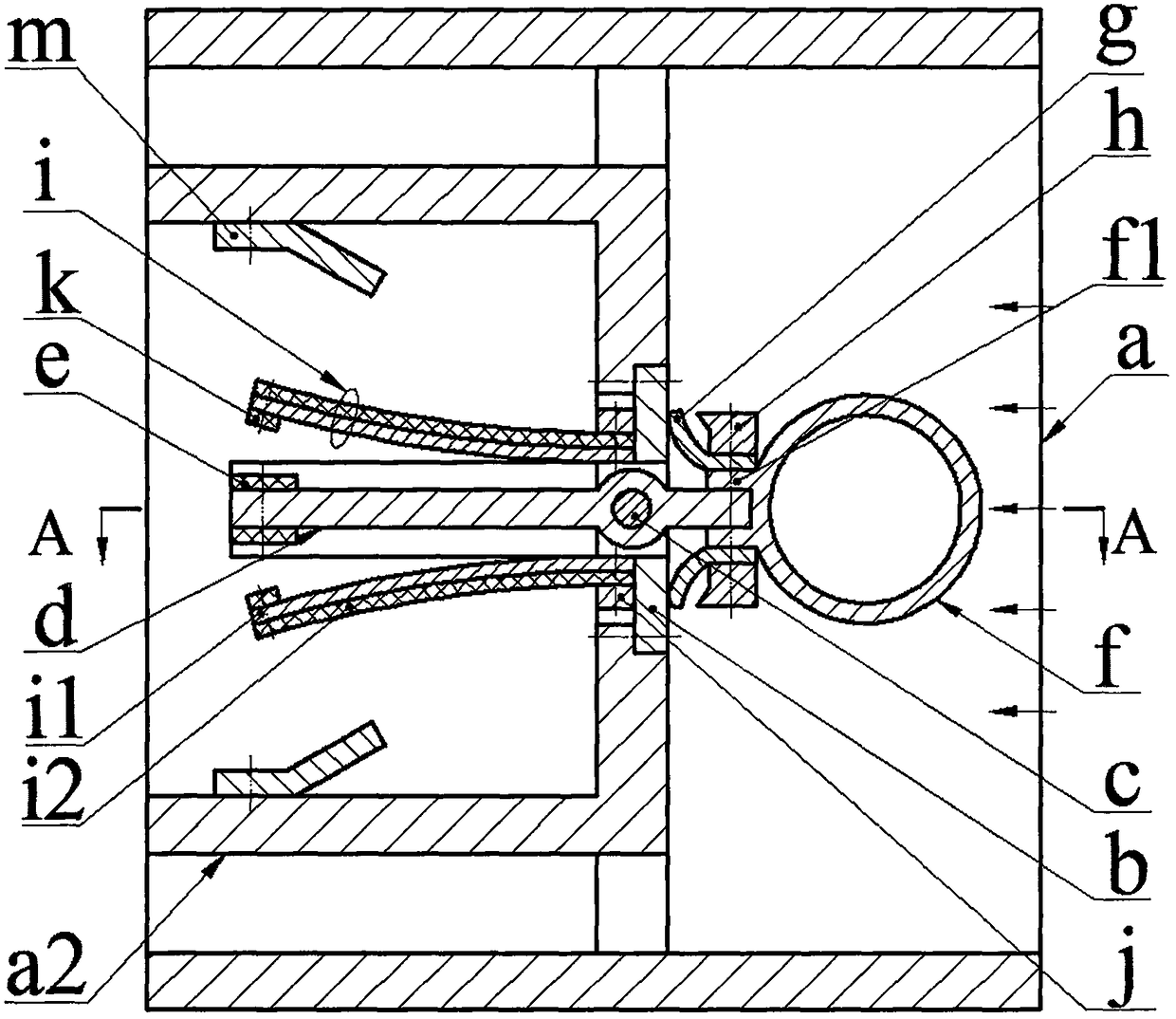

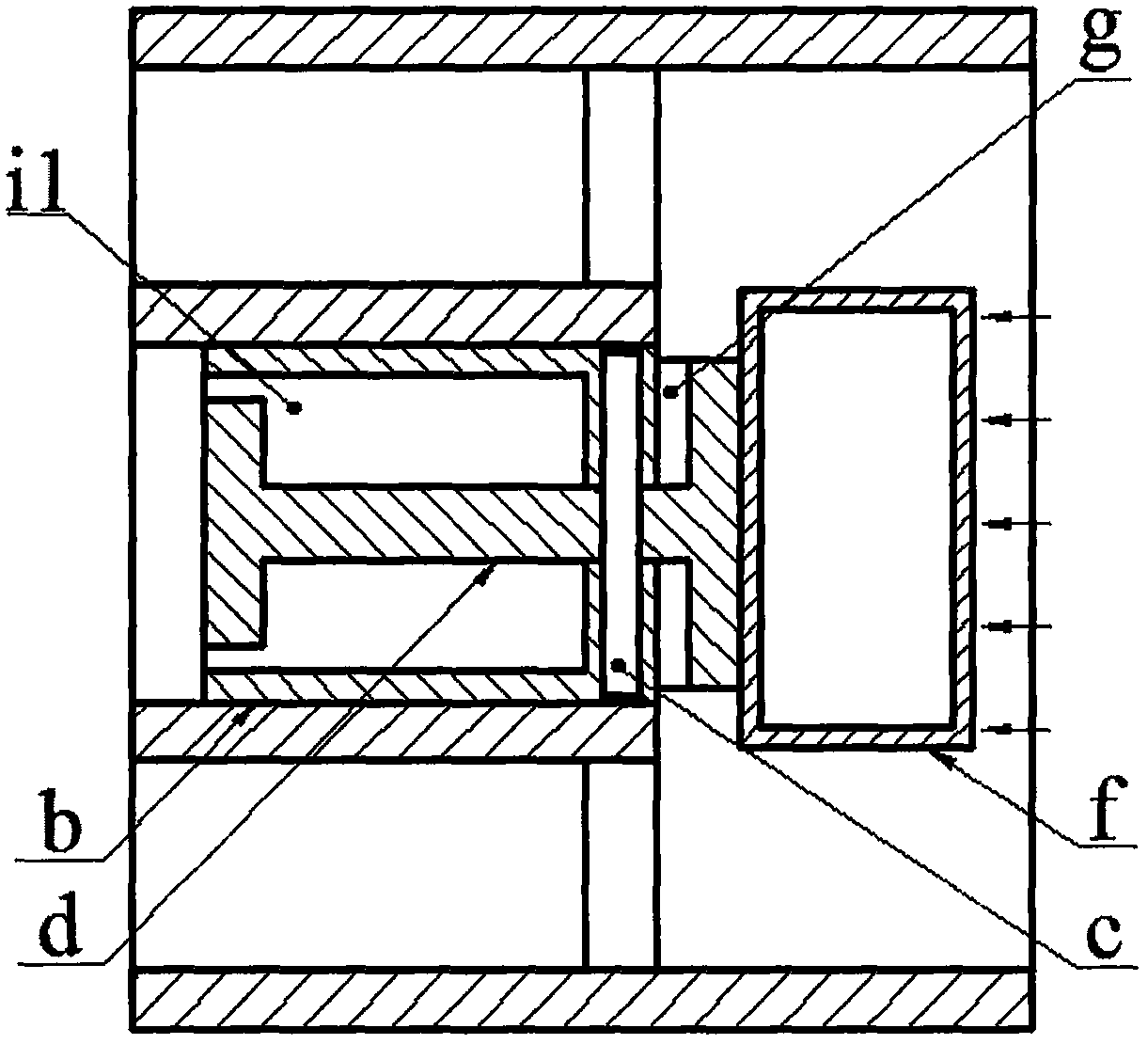

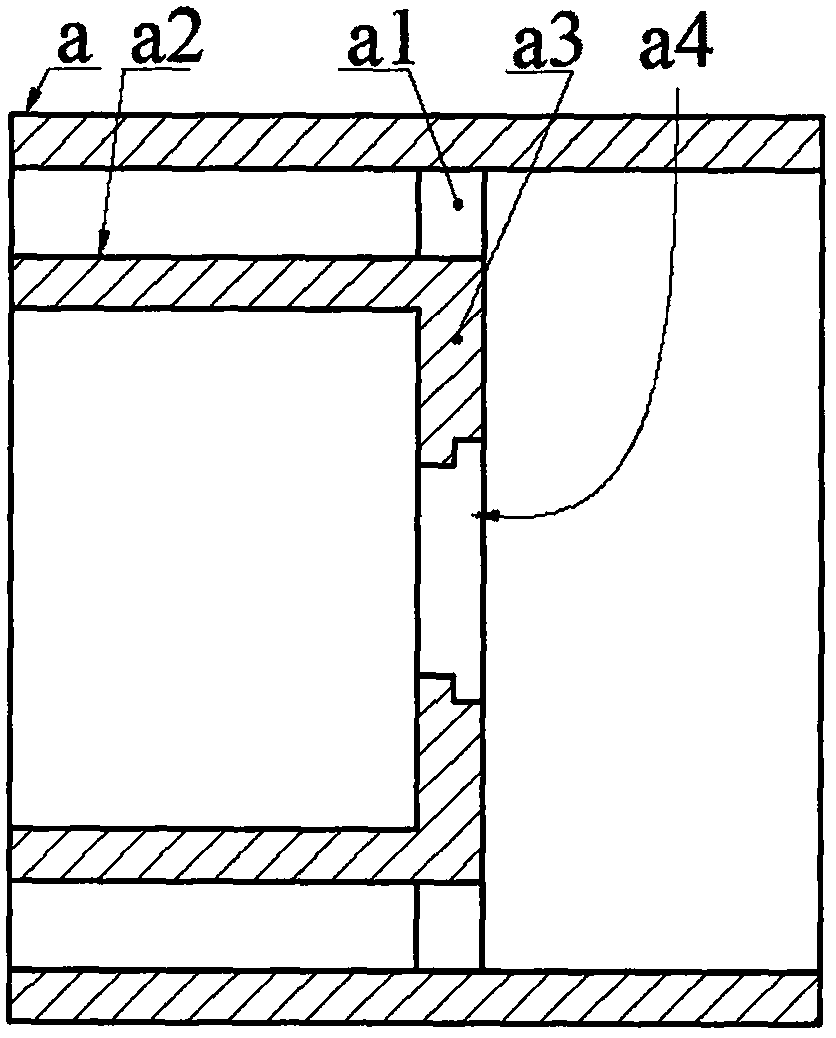

[0014] An inner cylinder a2 is installed on the inner wall of the pipe a through the ear plate a1, the cross section of the inner cylinder a2 is square, a square hole a4 is arranged on the bottom wall a3 of the inner cylinder a2, and a bracket is installed on the boss of the square hole a4 through screws b. There is a through hole b2, two bracket bosses b3 and two limit plates b5 on the bracket bottom plate b1, the through hole b2 is located at the center of the bracket bottom plate b1, and the two bracket bosses b3 are symmetrically distributed on the sides of the through hole b2 On both sides, coaxial pin holes b4 are provided on the two bracket bosses b3, and the pin shaft c is sleeved in the pin hole b4; the pin hole d1 of the lever d is set on the pin shaft c, and the lever d is connected to the Through the through hole b2, the left arm d2 of the lever is placed in the inner tube a2, the left arm d2 of the lever is longer than the right arm d3 of the lever, the end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com