Device used for controlling slab processing

A technology of equipment and slabs, which is applied in the field of equipment for controlling slab processing, can solve problems such as uneven heating and poor quality of control panels, and achieve the effects of wide processing range, good lamination effect, and good slab quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

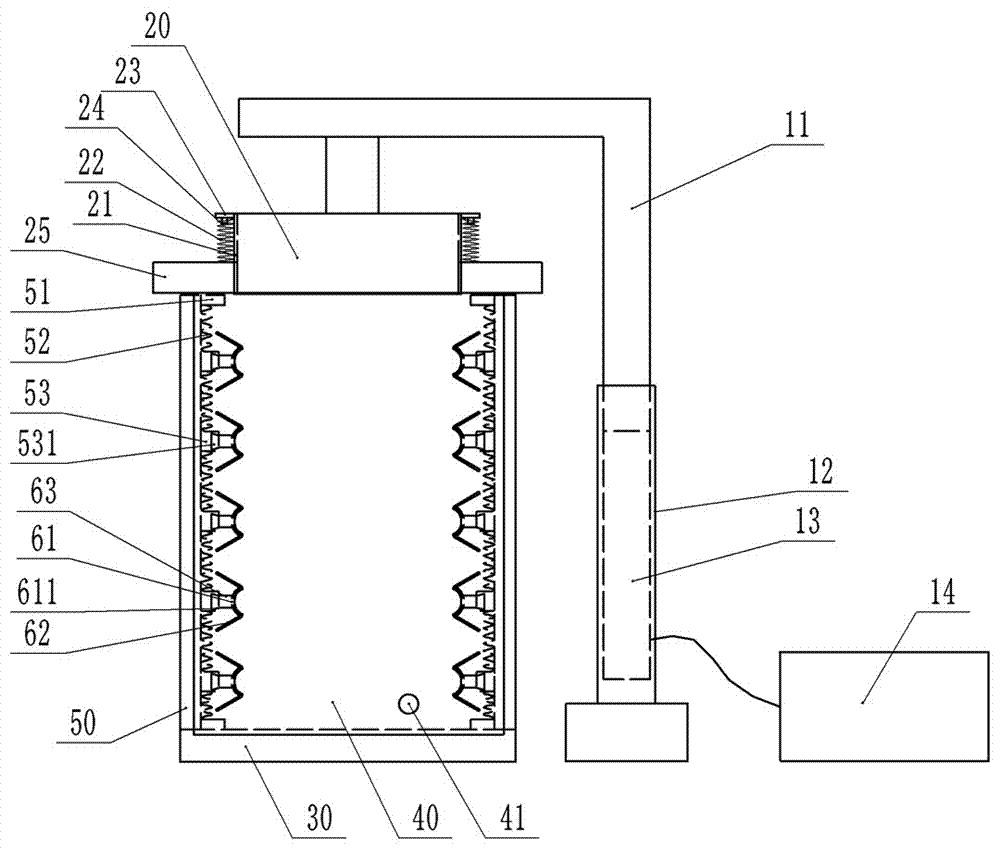

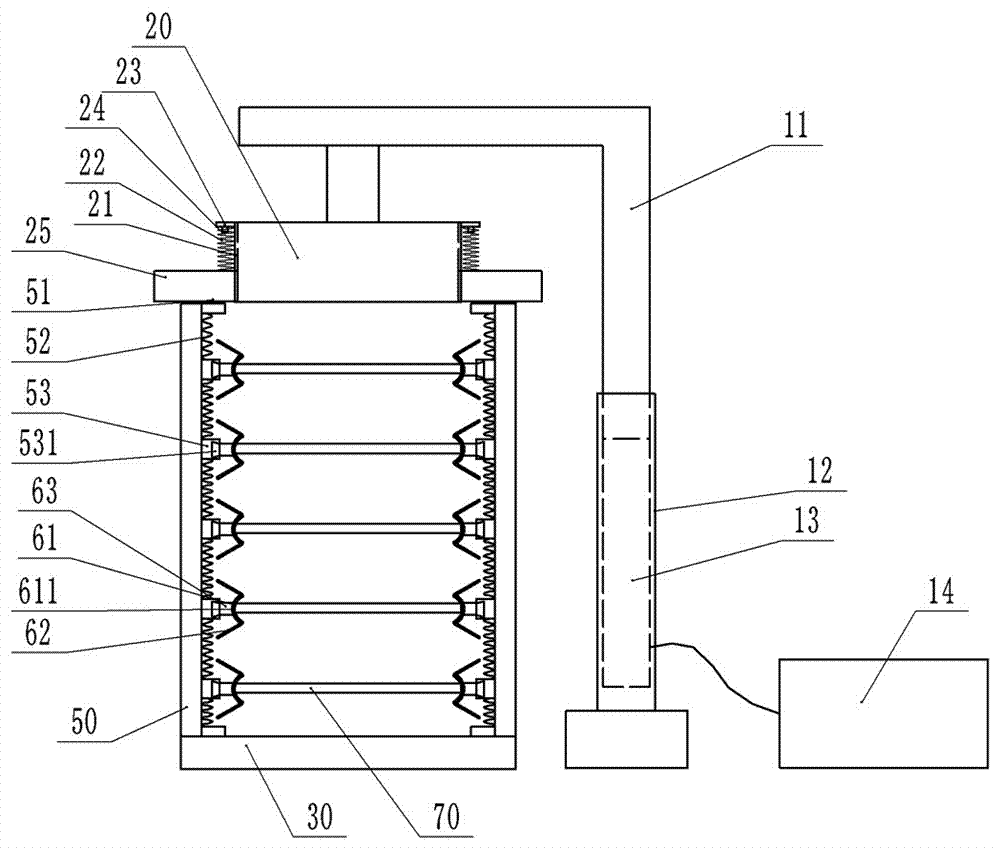

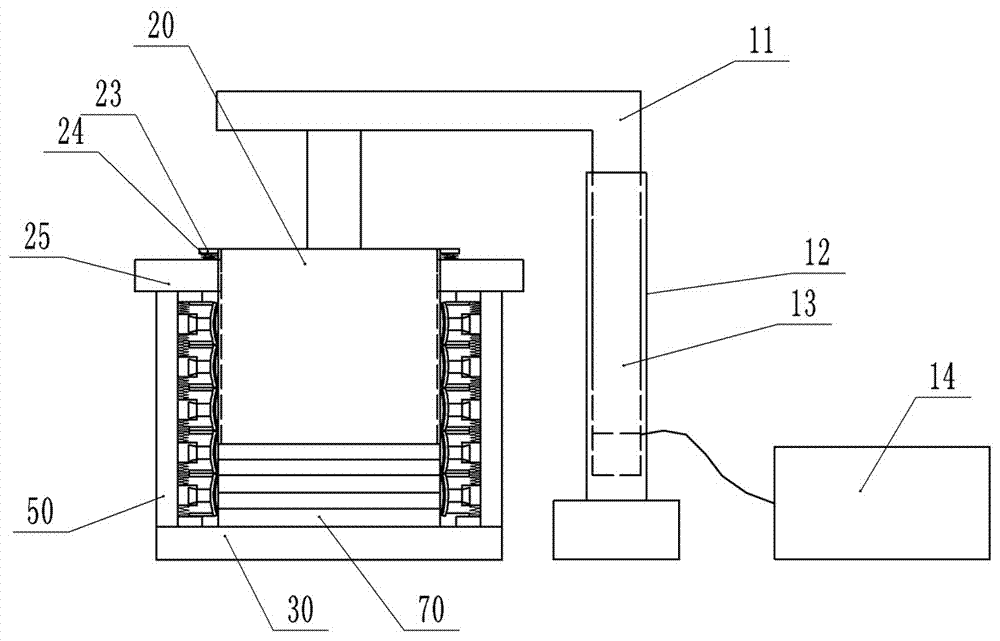

[0018] The reference signs in the drawings of the description include: upper bracket 11, lower bracket 12, hydraulic chamber 13, hydraulic pump 14, pressure plate 20, vertical groove 21, spring 22, counter plate 23, switch 24, side pressure plate 25, base 30, Baffle plate 40, fixed pin 41, telescopic plate 50, support plate 51, corrugated plate 52, chute seat 53, chute 531, spring sheet 61, rubber pad 611, electric heating plate 62, engaging block 63, PCB board 70.

[0019] like figure 1 , figure 2 As shown, the equipment for controlling slab processing includes a support, a pressing plate 20, a hydraulic pump 14, a base 30, a corrugated plate 52, a chute seat 53 and clamping blocks, and the support includes an upper support 11 and a lower support 12, and the lower support 12 A hydraulic chamber 13 is provided inside, and a hydraulic pump 14 communicates with the hydra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com