Thermal conductive damping plug-in locking assembly for electronic equipment

An electronic equipment and plug-in technology, which is applied in the installation of support structures, clamping/extracting devices, etc., can solve the problems of easy deflection of the bar-shaped slider, large shaking of the bar-shaped slider, and failure of the threads to mesh normally, so as to avoid Serious wear and tear of the screw teeth, good heat dissipation and vibration damping ability, and the effect of avoiding slippage and jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

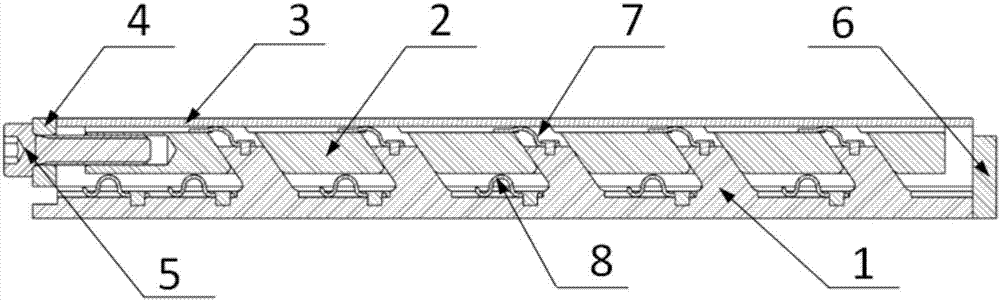

[0027] see figure 1 , figure 2 with image 3, a high thermal conductivity self-vibration-damping locking assembly for electronic modules or equipment inserts, which has a bar-shaped slider 2 mounted on a bar-shaped base 1 and can slide up and down, and a housing installed on the bar-shaped slider 2 Body 3, screw rod 5 and positioning block 4. A plurality of slanted columns or slanted teeth are designed on the strip base 1 along the longitudinal direction, and the same number of slanted holes or slanted slots are provided at the corresponding positions on the bar-shaped slider 2. Install the bar-shaped slider 2 on the bar-shaped base 1, the bar-shaped base 1 and the bar-shaped slider 2 are integral structures; the outer shell 3 is set on the bar-shaped slider 2, and the fixed limit block 4 is installed on the outer shell 3 left end, the screw rod 5 passes through the limit block 4 and is threadedly connected with the bar slider 2, and the limit block 6 is installed on the ...

Embodiment 2

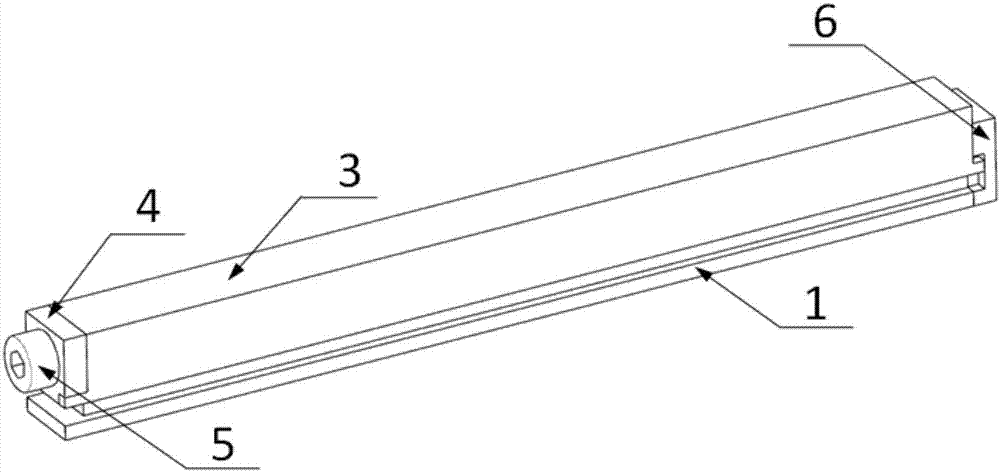

[0030] refer to Figure 4 with Figure 5 . The difference between this embodiment and Embodiment 1 is that the outer casing 3 and the bow-shaped shrapnel 7 are removed, and the left end of the bar-shaped base 1 is designed with a limit guide groove, and the fixed limit block 4 is installed in the limit guide groove; The oblique through hole is changed into an oblique blind hole, and its right end face is designed with a limit post to cooperate with the limit block 6. Other compositional structures and figure 1 The described embodiment is the same.

Embodiment 3

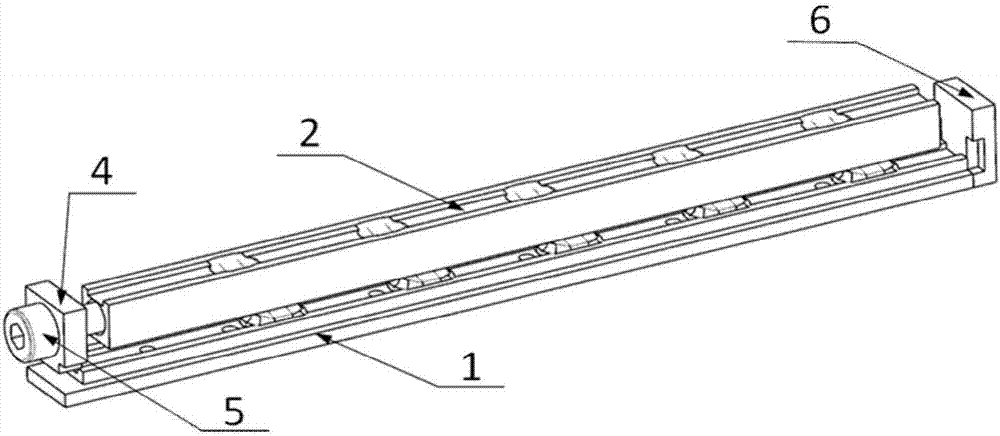

[0032] refer to Image 6 with Figure 7 . The difference between this embodiment and Embodiment 1 is that the bow-shaped shrapnel 7 is removed, the slanted column on the upper part of the strip base 1 is changed to helical teeth, and the slanted through hole of the bar slider 2 is changed to a chute. Cooperate, the bar-shaped slider 2 is inserted on the bar-shaped base 1, and at least two Ω-shaped shrapnel 8 are riveted on the plane below the bar-shaped slider 2 . Other compositional structures and figure 1 The described embodiment is the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com