Method for monitoring a color standard in a printing machine

A standard and printing process technology, applied to the general parts of printing machinery, printing machines, printing, etc., can solve problems that cannot be changed and cannot be considered, and achieve the effect of saving time and reducing waste pages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

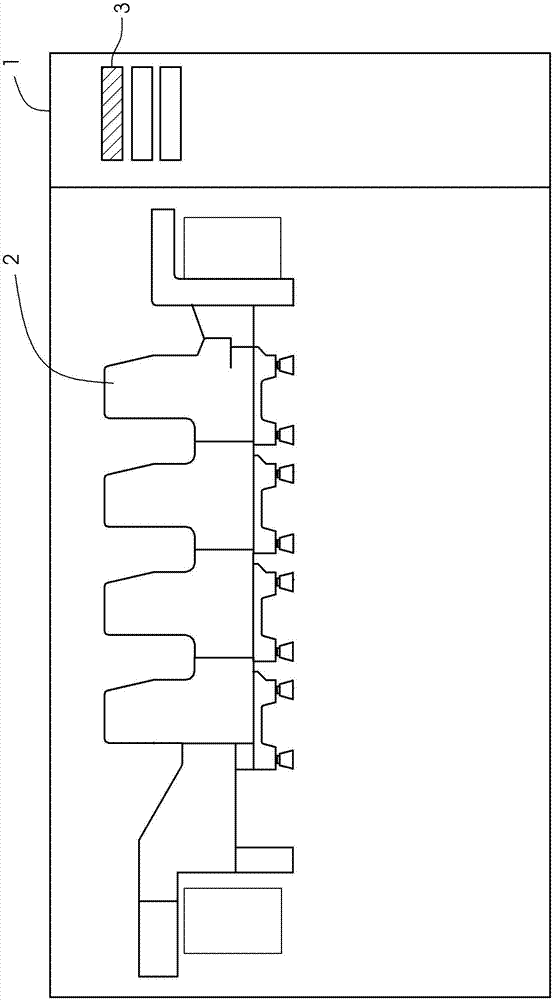

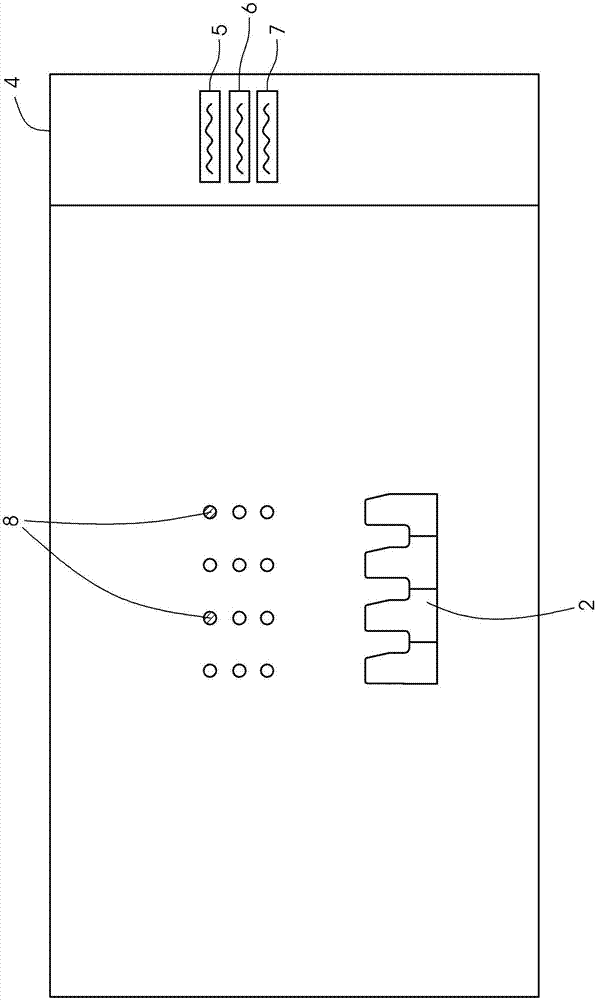

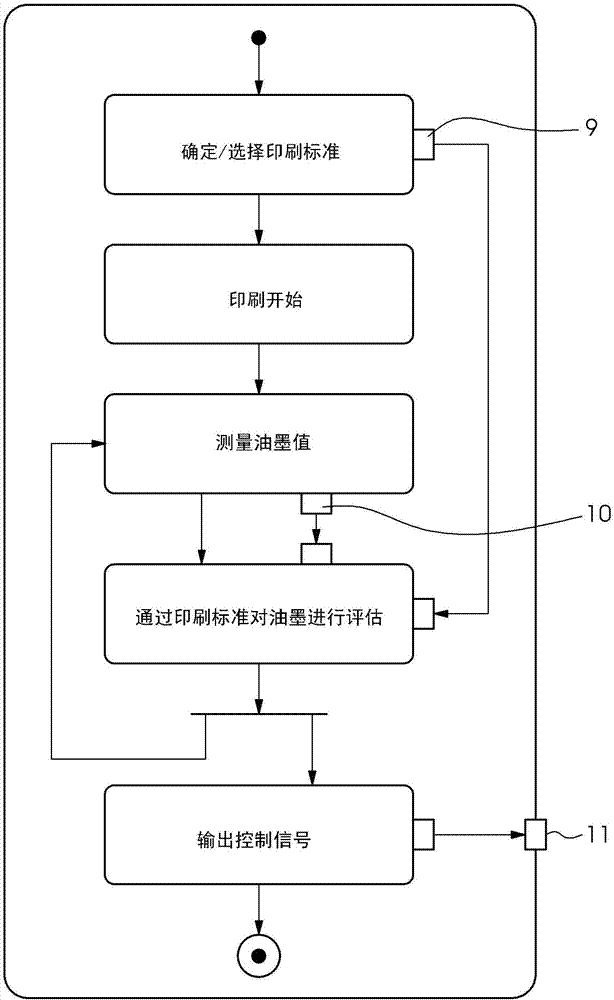

[0026] In a preferred embodiment variant, the method according to the invention is carried out by the assistance system 18 . here, in Figure 4 The schematic structure of this auxiliary system 18 is shown in . The system 18 includes a printing press 12 whose print quality is to be monitored and a control computer 16 of the printing press, on which an auxiliary system 18 is implemented as a software application. In this case, the control computer 16 also has an input device 17 and a display 15 . In this case, the control computer 16 and the display 15 (like the input device 17 ) can be integrated in the printing press 12 in a preferred embodiment as a remote control station. Furthermore, the control computer 16 is connected to a database 13 on which the parameters 5 , 6 , 7 for the coloring standard 9 to be used by the auxiliary system 18 are stored. In this case, the database 13 can be stored not only in the memory of the control computer 16 but also in an external memory w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com