Optical disc driver connector and improvement method for solving problem of floating of optical disc driver connector

A technology for optical disc drives and connectors, which is applied to optical drive connectors and the field of improving the floating height of optical drive connectors. It can solve the problems of upward movement of pins, tilting, ODDConn floating heights, etc., and achieves low design and production costs. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

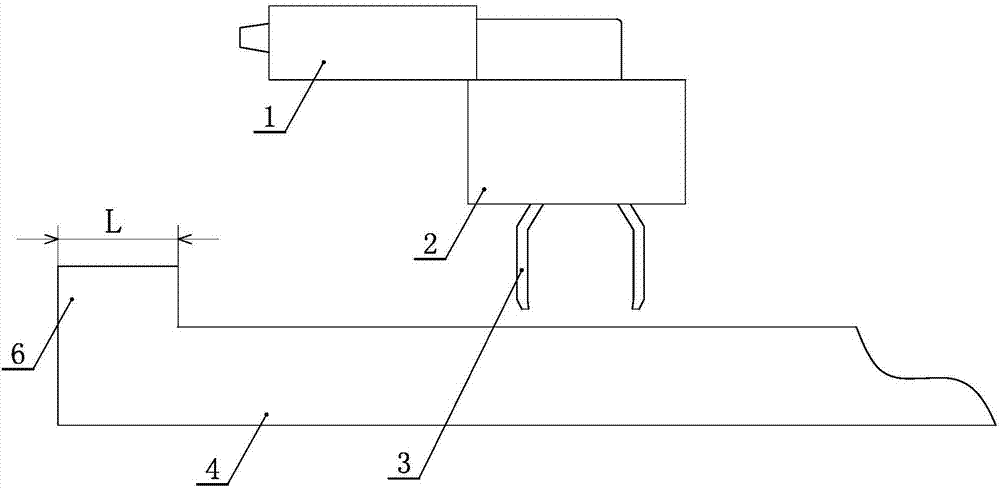

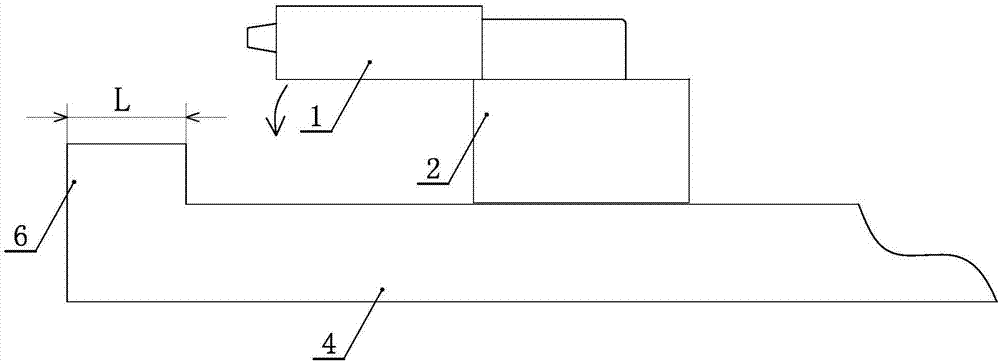

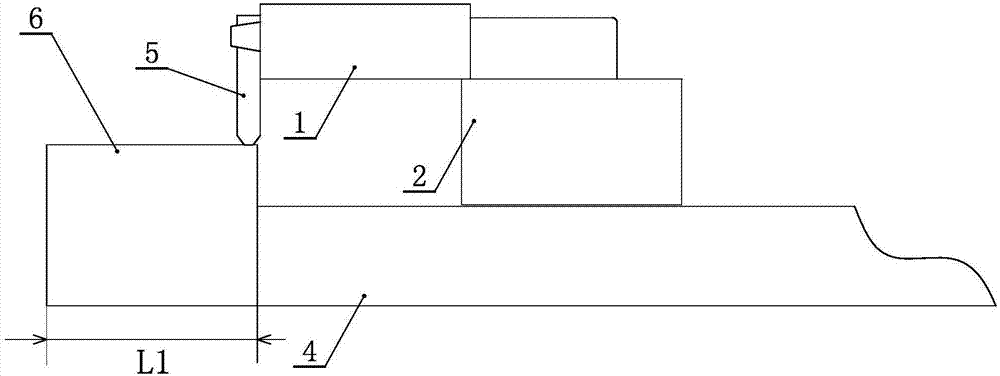

Embodiment 1

[0036] Embodiment one: if Figure 3 to Figure 5 As shown, the supporting device includes a top cover 5 and a PCB edge 6 arranged on the optical disc drive 1 . The top cover 5 is fixed on the side of the optical disc drive 1 away from the connector 2 and extends downward. The top cover 5 can be made of hard plastic or metal according to needs. In the original design, the width of the PCB side 6 is L, but in the design of the present invention, the width of the PCB side 6 is L1, and L1 is greater than L. That is to say, in this invention, the side 6 of the PCB extends to the side close to the connector 2 to the bottom of the top cover 5 until the bottom of the top cover 5 abuts against the top surface of the side 6 of the PCB. The optical drive connector as a whole is supported, and the central position of the optical drive connector is balanced, so the optical drive connector will not be tilted and floated high. Moreover, the cooperation between the top cover 5 and the edge o...

Embodiment 2

[0038] Embodiment two: if Figure 6 to Figure 8 As shown, the supporting device includes a first fixing block 7 and an adjusting bolt 8 arranged on the optical disc drive 1 . The first fixing block 7 and the adjusting bolt 8 can be made of hard plastic or metal as required. The first fixed block 7 is fixedly arranged on the side of the optical disk drive 1 away from the connector 2. The first fixed block 7 is provided with an internally threaded hole. The adjusting bolt 8 is matched with the internally threaded hole and the head of the adjusting bolt 8 is fixed on the first above the block 7 , the screw part is below the first fixing block 7 and the end of the screw is against the top surface of the PCB 4 . During specific installation, the adjustment bolt 8 can be properly adjusted according to the fixed position of the optical disk drive connector to ensure the support of the adjustment bolt 8 to the optical disk drive connector.

[0039] Similarly, in order to prevent the...

Embodiment 3

[0041] Embodiment three: as Figure 9 As shown, the difference from the second embodiment is that the supporting device also includes a PCB edge 6 . The edge 6 of the PCB extends to the side close to the connector 2 to the bottom of the adjustment bolt 8 , and the bottom end of the screw rod of the adjustment bolt 8 leans against the top surface of the edge 6 of the PCB. In this way, the length of the adjusting bolt 8 can be shortened, and the supporting strength of the adjusting bolt 8 can be enhanced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com