Magnetic stabilization type contactor

A contactor and magnetic stabilization technology, which is applied in the direction of electromagnetic relays, electromagnetic relay details, relays, etc., can solve problems affecting the normal operation of contactors, low electromagnetic utilization rate, and adverse effects of electrical appliances, so as to improve electromagnetic utilization rate, The effect of prolonging the service life and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

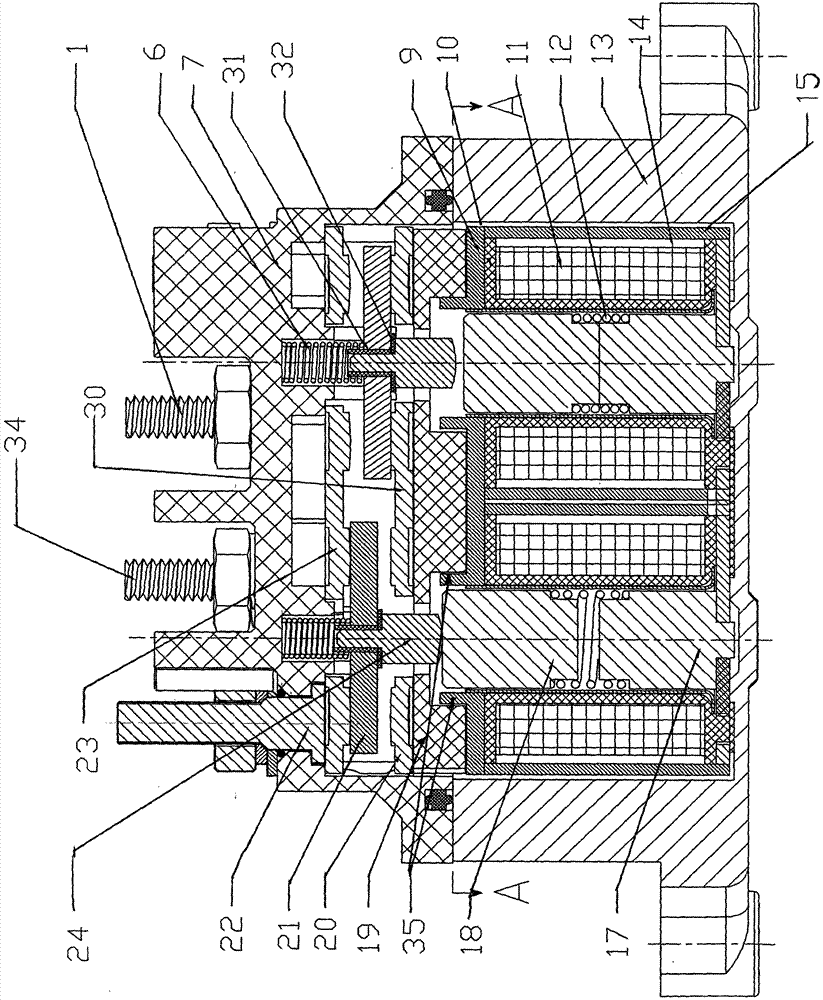

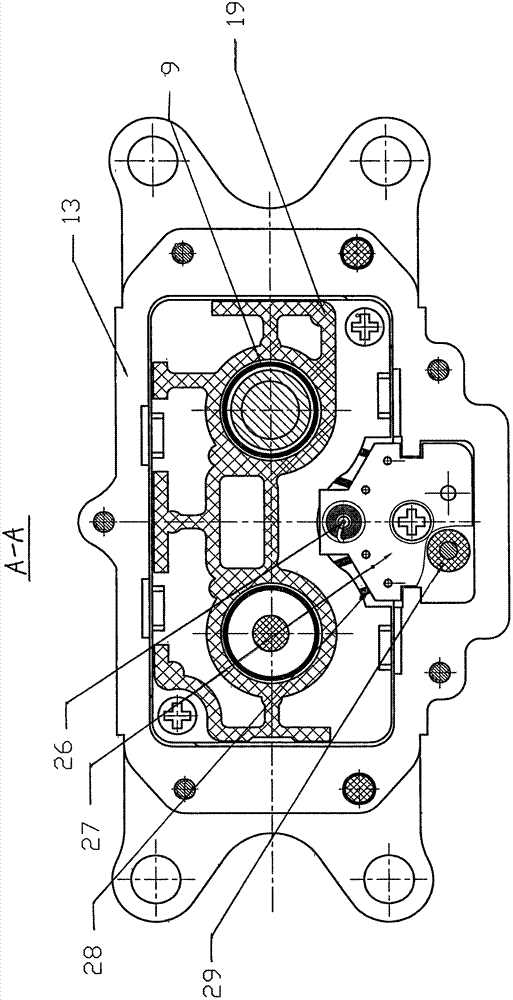

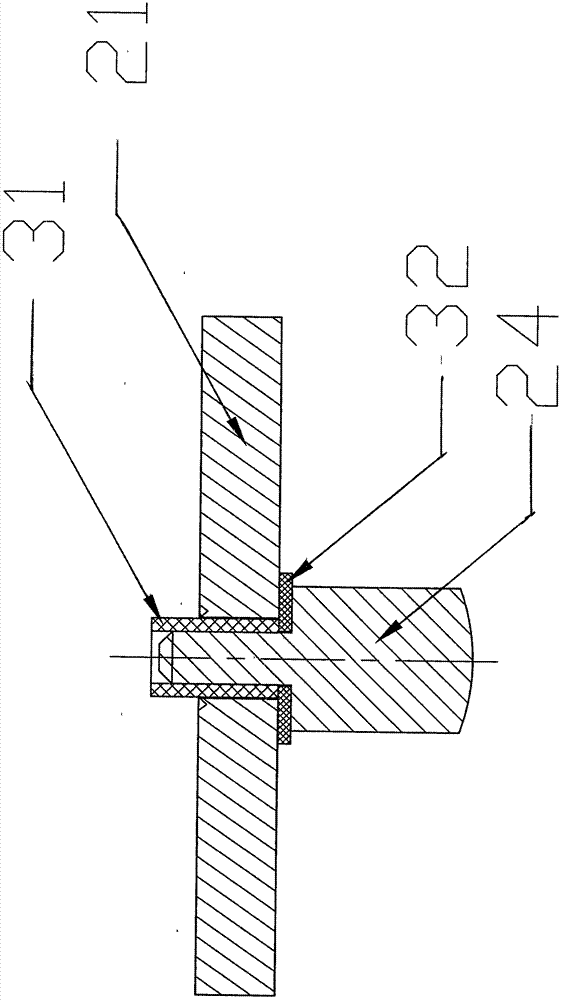

[0012] refer to figure 1 , figure 2 , image 3 It can be seen that the stabilized magnetic contactor of the present invention is composed of electromagnetic components (also known as electromagnetic components), load components, and housing components, wherein the electromagnetic components include a moving iron core 18, a static iron core 17, a coil 11, a coil frame 10, a magnetic The sheet 9 and the cover plate 19, the housing member includes the upper cover shell 7, the base 13, the load member includes the upper contact sheet 30, the lower contact sheet 23, the middle contact bridge 21, the conductive sheet 20, the top post 24, and the overtravel spring 6, The magnetic sheet 9 has a protruding structure 35 (manufactured by a stretching process) connected to the cover plate 19 , and an insulating paper frame 14 and a magnetic yoke 15 are installed between the coil 11 and the inner wall of the base 13 . Between the top post 24 and the middle contact bridge 21, a vertical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com