Heat conducting component, high-capacity battery equipped with heat conducting component and manufacturing method of high-capacity battery

A heat-conducting component and large-capacity technology, applied in the direction of secondary batteries, battery pack components, circuits, etc., can solve the problems of increasing the difficulty of leak prevention, complex structure, high thermal resistance, etc., to improve structural strength and stability, improve Heat dissipation efficiency and the effect of improving heat transfer speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

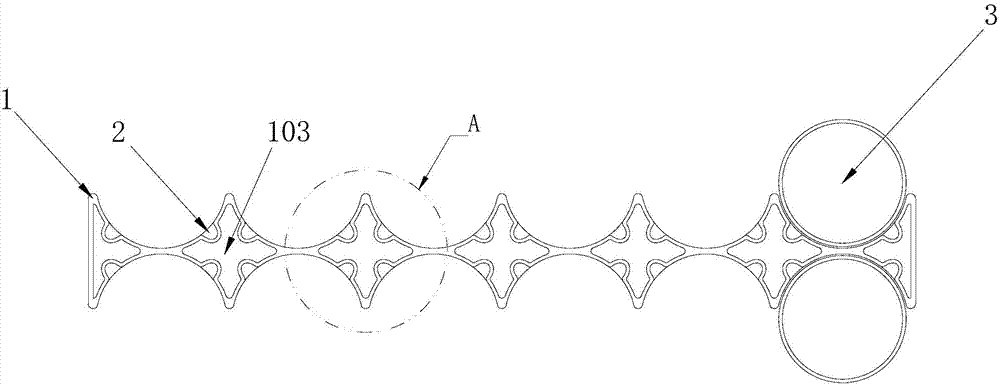

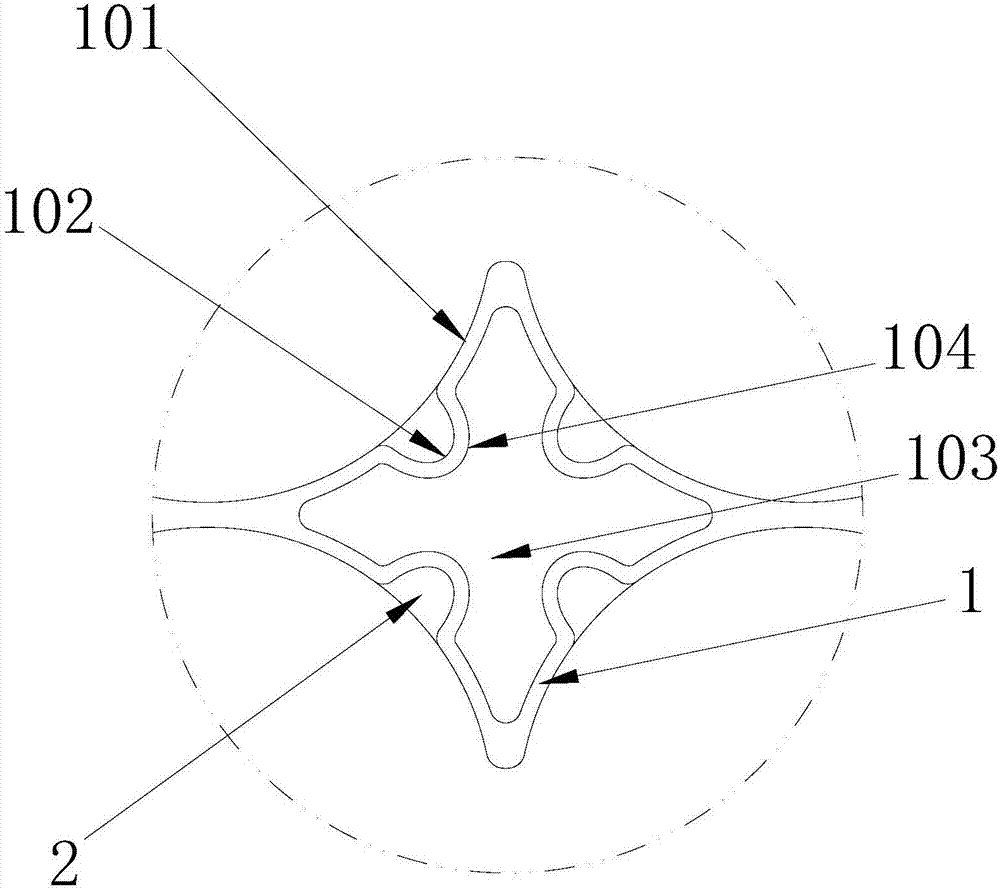

[0063] Figure 1 to Figure 10 A specific application example of the heat conduction assembly of the present application in a large-capacity battery (also called a battery module in the industry) is shown. The heat conduction assembly includes a hard heat conductor 1, the side of the hard heat conductor 1 is formed with a plurality of grooves 101 adapted to the outer wall of the cylindrical battery, and a flexible heat conductor is formed on the groove wall of each groove 101 The accommodating chamber 102, and the flexible heat conducting body 2 is arranged in the accommodating chamber 102 of the flexible heat conducting body. The large-capacity battery includes a battery holder 5 with numerous battery insertion holes, and a large number of cylindrical batteries 3 respectively inserted in each battery insertion hole, and each battery insertion hole is distributed in a matrix on the battery holder 5, so the insertion The various cylindrical batteries 3 contained in the battery ...

Embodiment 2

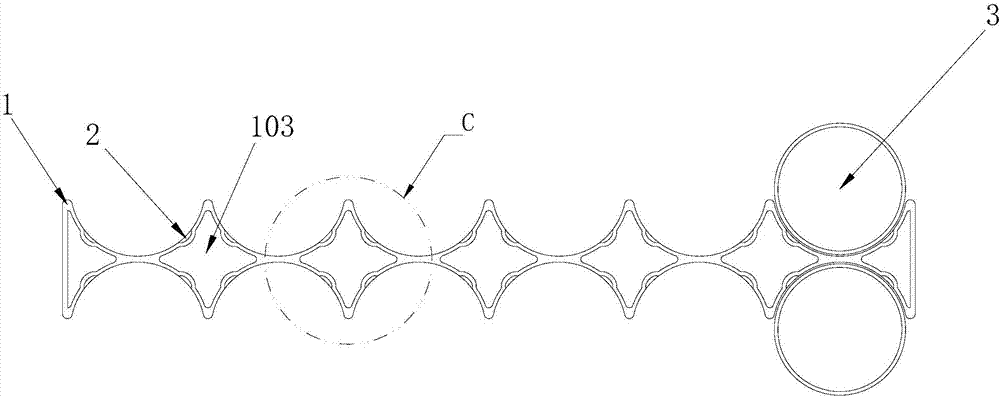

[0084] refer to Figure 11 As shown, in this embodiment, the heat conduction assembly also includes a rigid heat conductor 1, and the side of the rigid heat conductor 1 is formed with a plurality of (4) grooves 101 adapted to the outer wall of the cylindrical battery, each A flexible heat conductor accommodating cavity 102 is formed on the groove wall of the groove 101 , and a flexible heat conductor 2 is disposed in the flexible heat conductor accommodating cavity 102 . The main difference between this embodiment and the heat conduction assembly in Embodiment 1 is that only one expansion hole 103 is provided in the rigid heat conduction body 1 . When the heat-conducting assembly is loaded into a high-capacity battery and deformed by extrusion, it will come into contact with four cylindrical batteries.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com