Three-dimensional structure for cardiac muscular tissue regeneration and manufacturing method therefor

A three-dimensional structure and tissue technology, applied in tissue regeneration, biochemical equipment and methods, tissue culture, etc., can solve problems such as difficulty in fixing organs, high mortality rate, expensive treatment costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0094] Preparation Example 1: Preparation of the first bioprinting composition

[0095] 1-1: Preparation of acellular extracellular matrix

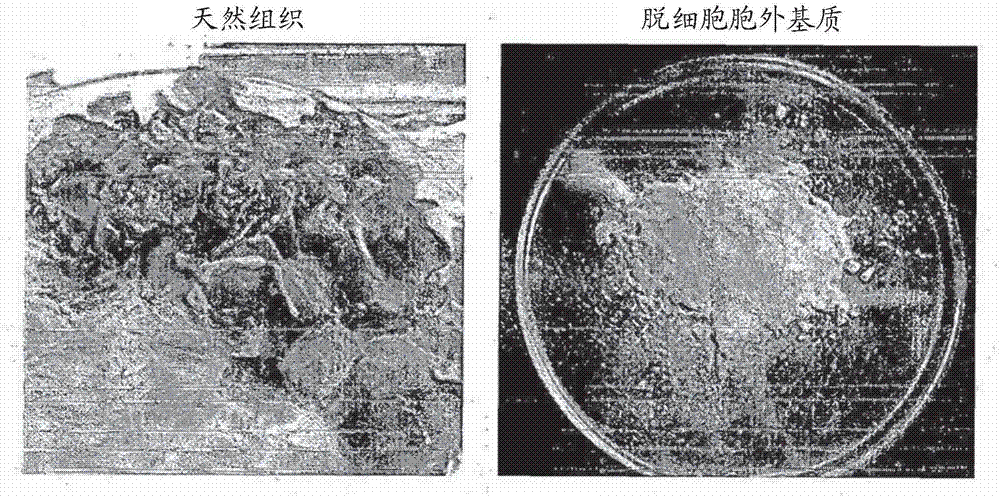

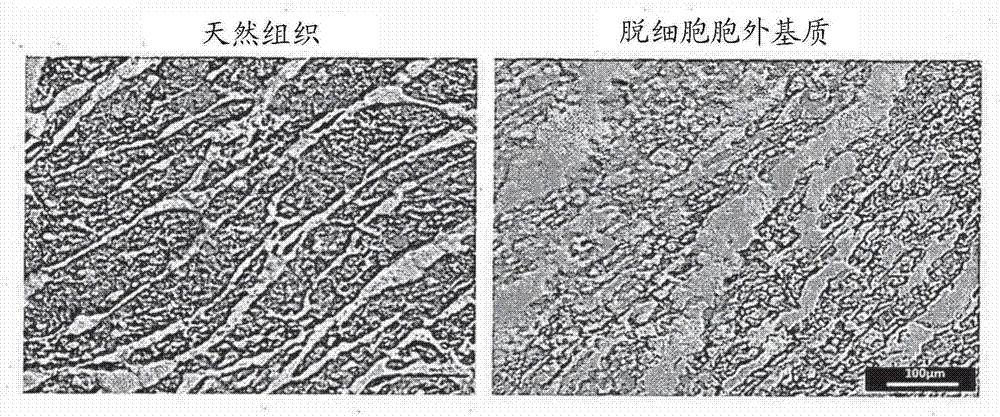

[0096] Acellular extracellular matrix (hereinafter referred to as 'hdECM') was prepared using porcine heart tissue according to the method disclosed in Falguni Pati et al., Nat Commun. 5, 3935 (2014). The prepared hdECM was finally lyophilized and stored frozen until use. Optical micrographs and tissue staining photos are shown in figure 2 middle.

[0097]1-2: Preparation of tissue engineering construct-forming solution in pregel form

[0098] Pour into liquid nitrogen to obtain lyophilized hdECM, and subsequently crush with a mortar and pestle. The obtained hdECM powder (330 mg) and pepsin (33 mg) (P7125, Sigma-Aldrich) were added to a 0.5 M acetic acid aqueous solution (10 ml), followed by stirring at room temperature for 48 hours. The resulting solution was kept below 10°C, and the pH was controlled to about pH7 by adding ribofla...

preparation example 2

[0101] Preparation Example 2: Preparation of the Second Bioprinting Composition

[0102] 2-1: Preparation of acellular extracellular matrix

[0103] Acellular extracellular matrix (hereinafter referred to as 'hdECM') was prepared using porcine heart tissue according to the method disclosed in Falguni Pati et al., Nat Commun. 5, 3935 (2014). The prepared hdECM was finally lyophilized and stored frozen until use. Optical micrographs and tissue staining photos are shown in figure 2 middle.

[0104] 2-2: Preparation of tissue engineering construct-forming solution in pregel form

[0105] Liquid nitrogen was poured into the obtained lyophilized hdECM, and then pulverized with a mortar and pestle. The obtained hdECM powder (330 mg) and pepsin (33 mg) (P7125, Sigma-Aldrich) were added to a 0.5 M acetic acid aqueous solution (10 ml), followed by stirring at room temperature for 48 hours. The resulting solution was kept below 10°C, and the pH was controlled to about pH7 by adding...

Embodiment 1

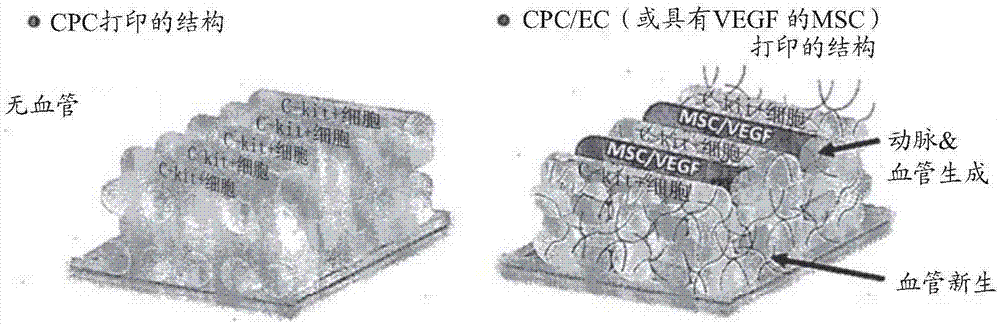

[0111] Example 1: Preparation of three-dimensional constructs for tissue engineering

[0112] The first bioprinting composition and the second bioprinting composition prepared in Preparation Examples 1 and 2 were used to fabricate a three-dimensional structure.

[0113] Specifically, the polycaprolactone (PCL) backbone was loaded on the syringe (the first syringe) of the multi-head tissue and organ printing system (Jin-Hyung Shim et al., J. Micromech. Microeng. 22085014 (2012)), and heated to About 80°C to melt the polymer. The first bioprinting composition in pregel form obtained in Preparation Example 1 and the second bioprinting composition prepared in Preparation Example 2 were respectively loaded on additional syringes (second and third syringes), and the temperature was maintained below about 10°C. A thin PCL backbone with a linewidth below about 100 μm, a gap of about 300 μm, and a thickness of 120 μm was prepared by applying a pneumatic pressure of about 600 kPa to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com