A front directional stalk type banana stalk cutting and returning machine

A banana stalk and front-end machine technology, which is applied in the direction of cutters, harvesters, agricultural machinery and implements, etc., can solve the problems of waste of straw resources, easy entanglement of banana fibers, and time-consuming, so as to prevent waste of resources and environmental degradation , The structure of the whole machine is simple and compact, which is convenient for maintenance and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with specific examples.

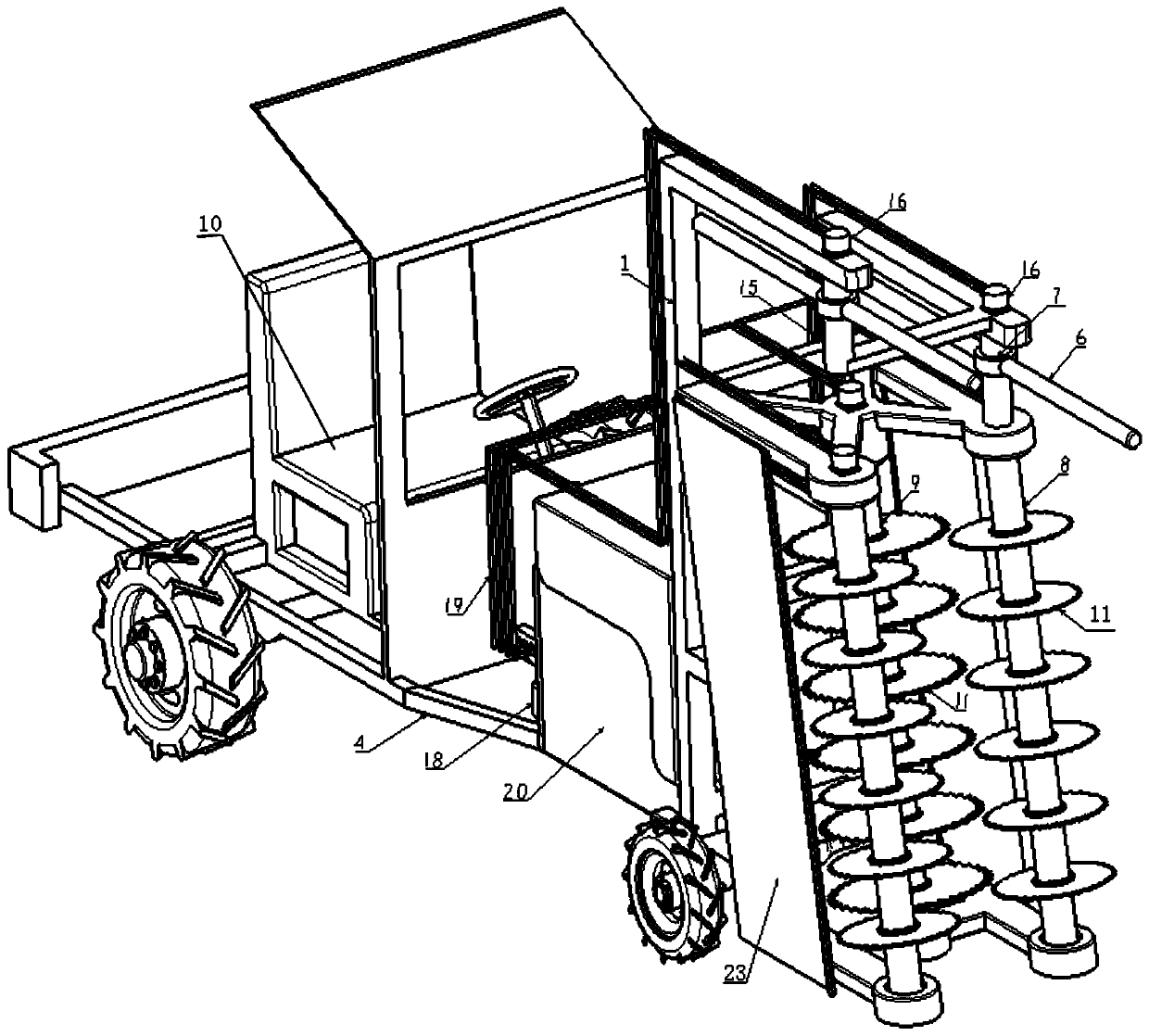

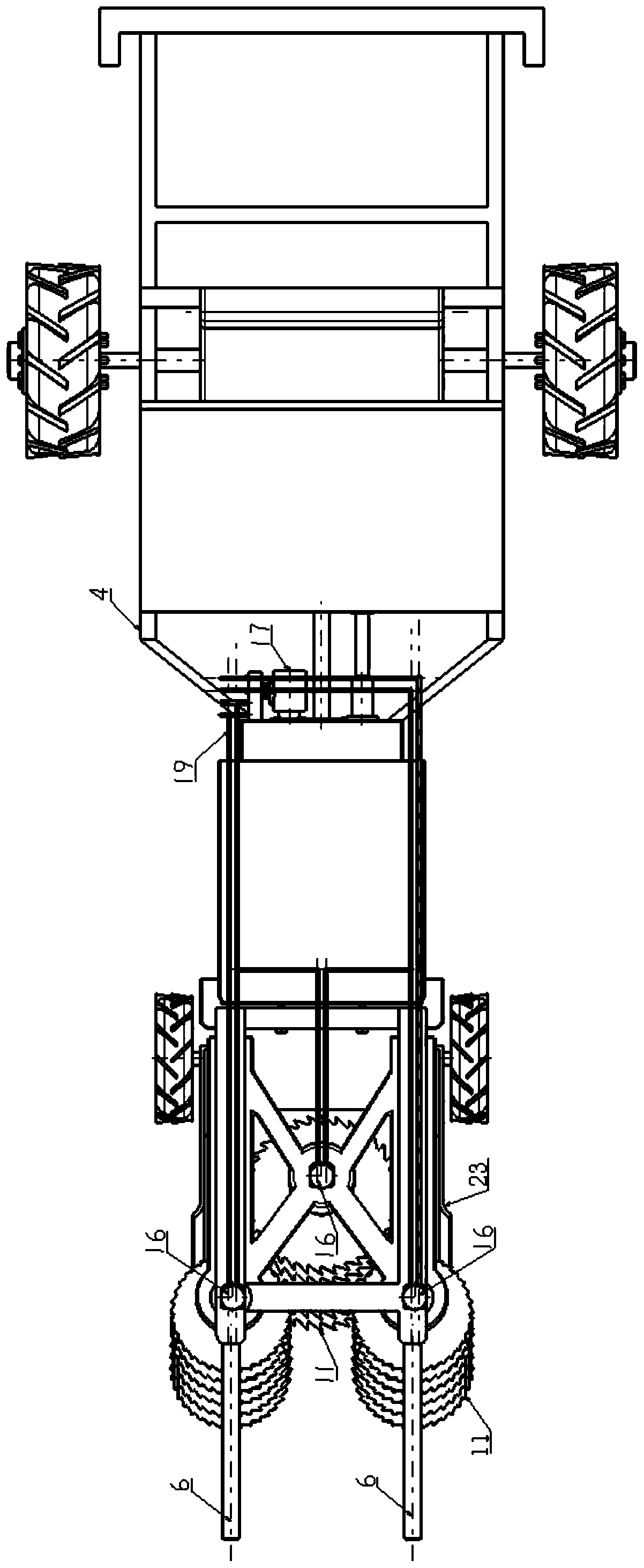

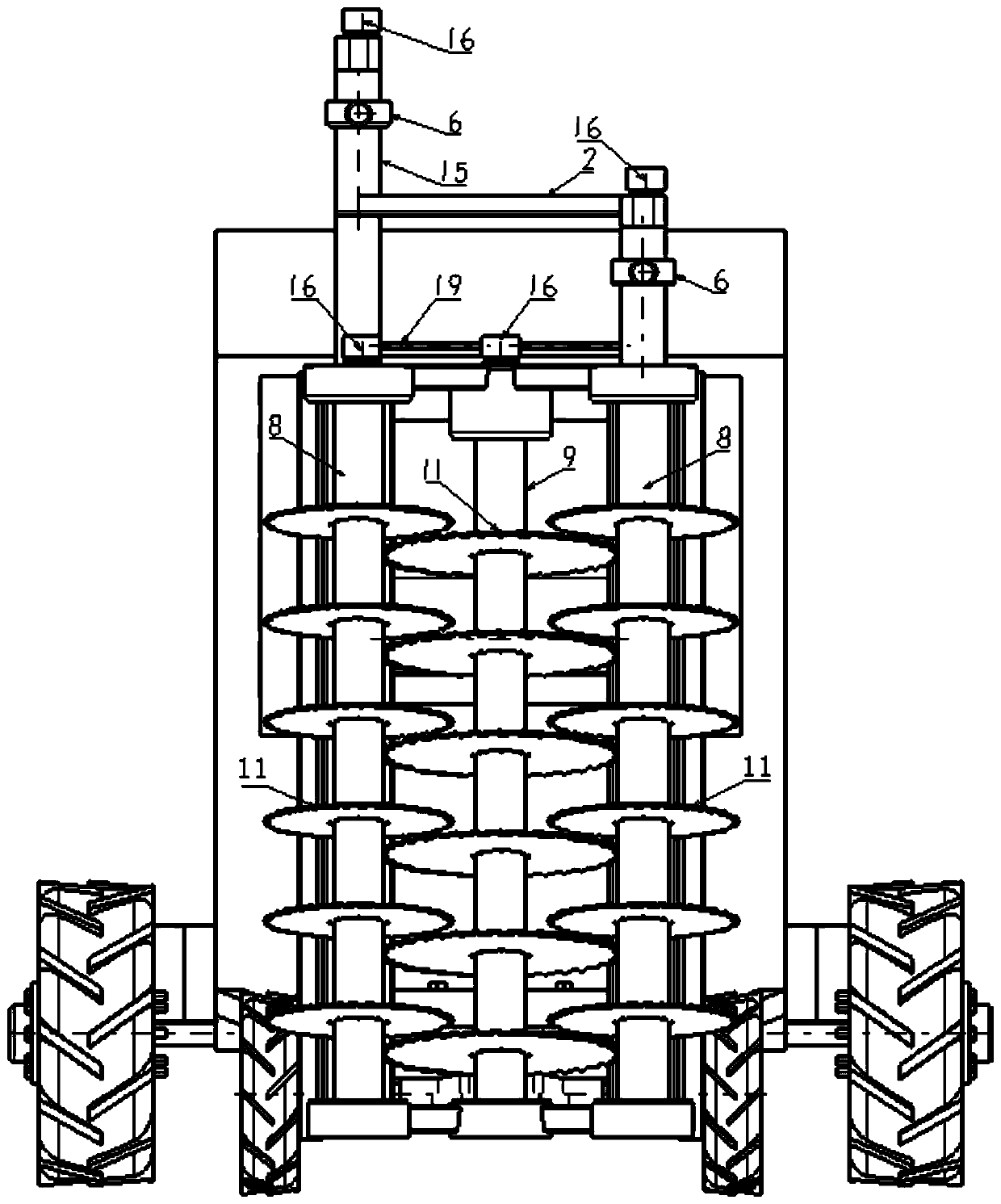

[0032] The front directional stalk support type banana stalk cutting and returning machine provided in this embodiment includes a returning machine body 10, a front frame installed at the front end of the field returning machine body 10, and a bearing connection with the front frame. The directional stem holding mechanism, the vertical multi-disc combination cutting device located at the front of the front frame and the hydraulic transmission device installed on the front frame.

[0033] see Figure 1-Figure 5 As shown, the front frame includes: side beams 1 on both sides, cross beams 2, side beams 3, and underframe 4. The side beams 1 on both sides are parallel to each other and vertically arranged on both sides of the front end of the engine 20 of the hydraulic transmission device. Both ends of the crossbeam 2 are vertically fixed to the two side beams 1 , one end of the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com