Glutinous rice flour used for quick-frozen glue pudding, and preparation method thereof

A technology of quick-frozen glutinous rice balls and glutinous rice flour, which is applied in the fields of application, edible oil/fat, and food science. The effect of water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

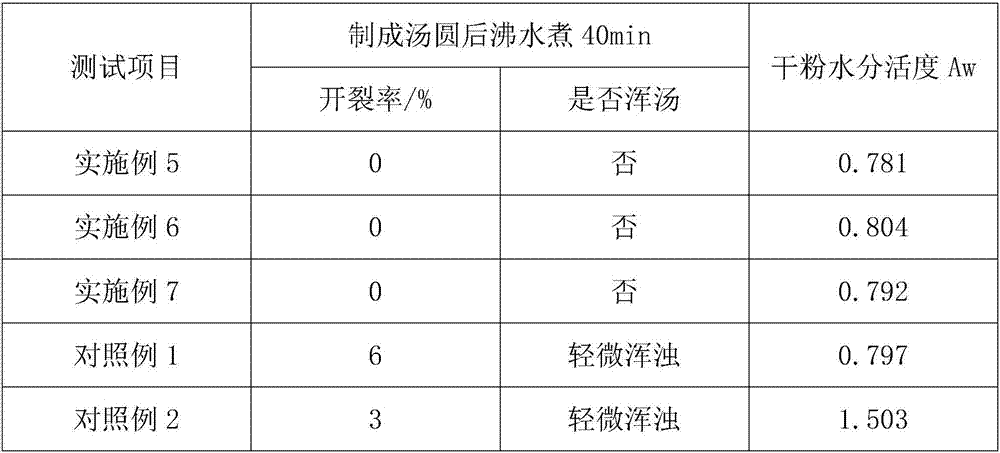

Examples

Embodiment 1

[0021] The glutinous rice flour for quick-frozen glutinous rice balls comprises the following raw materials in parts by weight: 80 parts of glutinous rice, 30 parts of waxy corn, 10 parts of yam starch, 0.3 part of salad oil, 1 part of oxidized hydroxypropyl starch and 1 part of compound phosphate.

Embodiment 2

[0023] The glutinous rice flour for quick-frozen glutinous rice balls comprises the following raw materials in parts by weight: 100 parts of glutinous rice, 20 parts of waxy corn, 5 parts of yam starch, 0.8 part of salad oil, 1.5 parts of oxidized hydroxypropyl starch and 0.5 part of compound phosphate.

Embodiment 3

[0025] A kind of glutinous rice flour for quick-frozen glutinous rice balls, its raw material comprises by weight: 100 parts of glutinous rice, 25 parts of waxy corn, 7 parts of yam starch, 0.5 part of salad oil, 1.2 parts of oxidized hydroxypropyl starch, 0.8 part of compound phosphate;

[0026] Among them, the composite phosphate is composed of sodium polyphosphate, sodium dihydrogen phosphate and sodium pyrophosphate, and the weight ratio of sodium polyphosphate: sodium dihydrogen phosphate: sodium pyrophosphate is 1:2:2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com