Coating material stirring and filtering device

A technology for filtering devices and coatings, applied in the fields of filtration and separation, mixer accessories, fixed filter element filters, etc., can solve the problems of unsatisfactory filtering and impurity removal, lack of coating stirring function, slow coating filtration rate, etc. The effect of blocking, fine coating, and increasing fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with specific embodiment, the technical scheme of this patent is described in further detail:

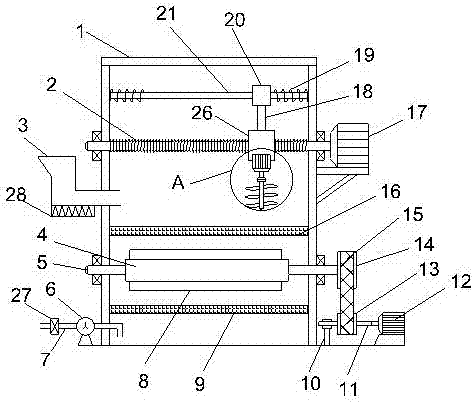

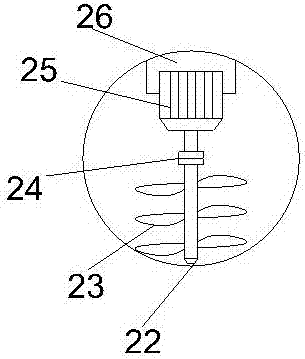

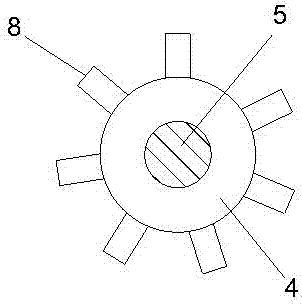

[0018] see Figure 1-3 , a paint stirring and filtering device, comprising a main body 1, characterized in that a sliding bar 21 is horizontally and fixedly installed in the main body 1, and a sliding block 20 is movably set on the sliding bar 21; The connecting rod 18 is fixedly installed on the bottom of the rod 2 and the slider 20, and the lower end of the connecting rod 18 is provided with a sleeve block 26. ; The bottom of the cover block 26 is provided with a third motor 25, the motor shaft of the third motor 25 is provided with a shaft coupling 24, the shaft coupling 24 is connected with a stirring shaft 22, and the stirring shaft 22 is provided with several stirring blades 23; the right end of the screw rod 2 is connected with a second motor 17, and the second motor 17 is located on the right side of the body 1; the body 1 is provided with a firs...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap