Method for preparing decalin based on the catalytic hydrogenation of tetralin at room temperature, and organic solvent

A room temperature, catalytic hydrogenation technology of tetralin, applied in the field of methods and organic solvents, can solve the problems of difficult controllable design and preparation, unsafe, high reaction temperature and pressure, and achieves a good green and environmentally friendly production process and good economy. and social benefits, the effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

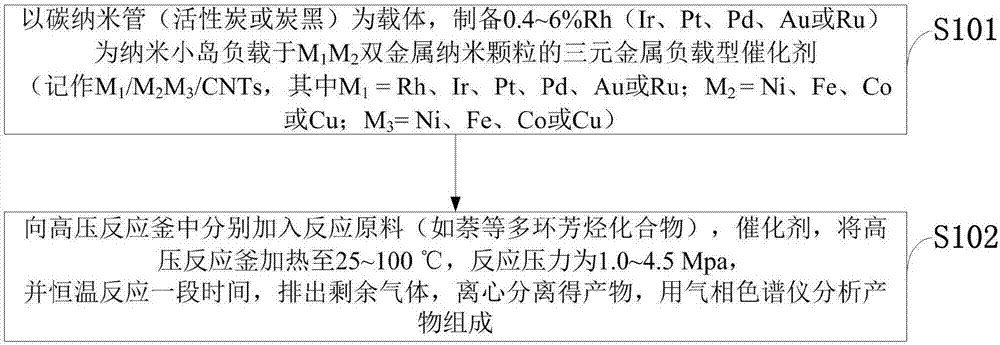

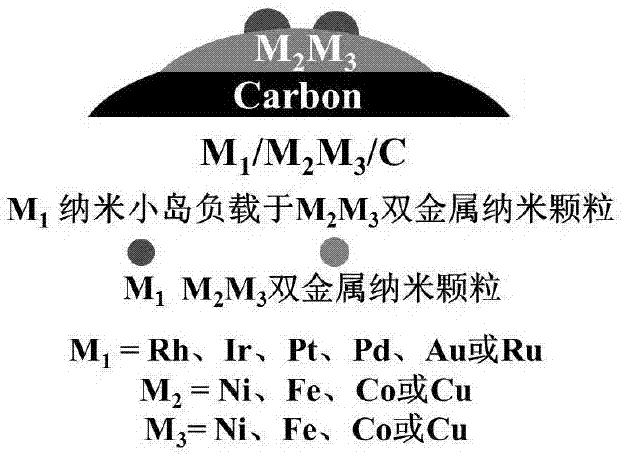

Method used

Image

Examples

Embodiment 1

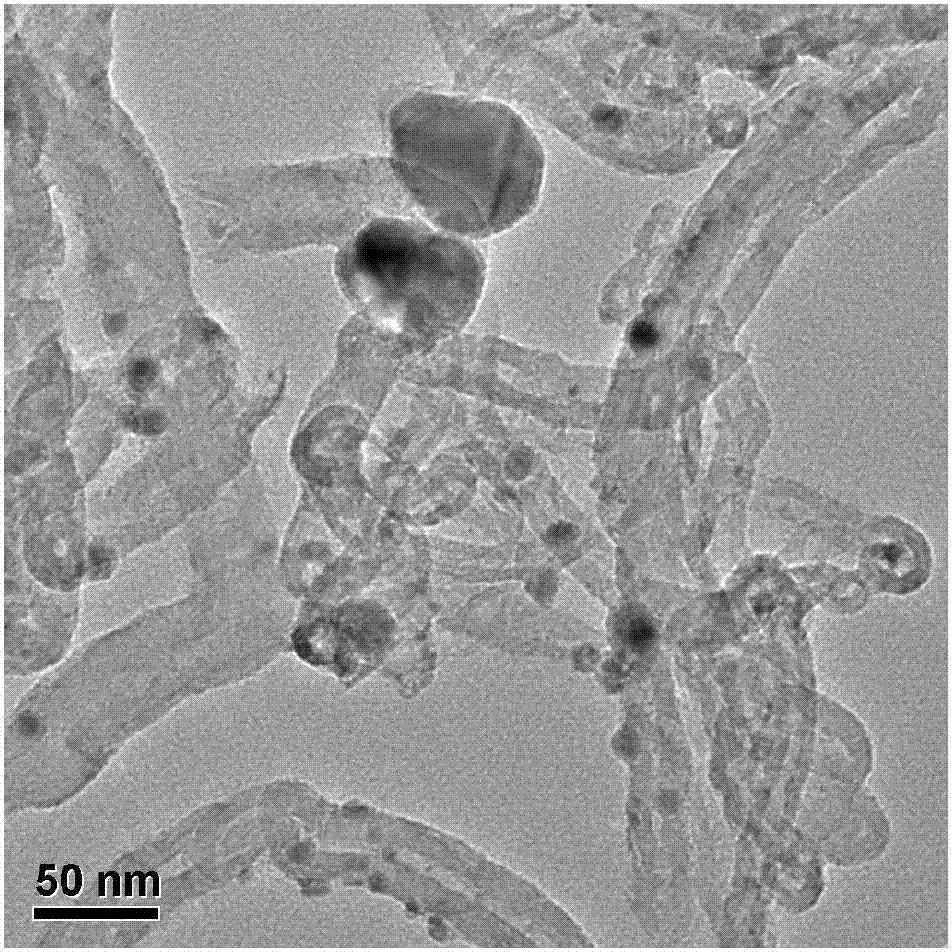

[0038] Synthesis of Rh / NiCo / CNTs catalyst:

[0039] 1. Weigh (0.45~3.6g) NiCl 2 ·6H 2 O and (0.45~3.6g) CoCl 2 ·6H 2 O, dissolved in (45-90mL) deionized water, stirred at room temperature to obtain a clear solution.

[0040] 2. Add (5~15mL) ethanol to the above NiCl 2 ·6H 2 O and CoCl 2 ·6H 2 O solution.

[0041] 3. Add (5-25mL) reducing agent solution (sodium borohydride, sodium hypophosphite, hydrazine hydrate, ascorbic acid, or polyols such as ethylene glycol).

[0042] 4. Add (0.45-2.5g) carbon nanotubes (activated carbon or carbon black).

[0043] 5. Heat the reaction solution to (100-200°C).

[0044] 6. Filter and wash several times with ethanol and water respectively.

[0045] 7. Vacuum dry and keep at 60°C for 6h.

[0046] 8. Weigh to get NiCo / CNTs nanomaterials, add to RhCl 3 In the solution, carry out in situ reduction, filter, wash, vacuum dry, and keep at 60°C for 6h.

[0047] 9. The catalyst is 99.999% N at a temperature of (600-900°C) 2 Medium calc...

Embodiment 2

[0051] In the high-pressure stirred tank reactor (MS-50-316L type, 50mL), add Ru / NiCo / CNTs catalyst 0.0500g successively, tetralin is 10.0mL; Pass into nitrogen (purity ≥ 99.999%) to remove the Air: feed hydrogen (purity ≥ 99.999%) to remove the nitrogen in the kettle, close the outlet valve, and then continuously feed hydrogen, when the reaction pressure is 4.5MPa. Start stirring at a stirring rate of 500r / min, and react at a constant temperature of 25°C for 11 hours. After the reaction stops, the remaining gas is discharged, and the product is obtained by centrifugation. The product composition is analyzed by gas chromatography. The reaction result is: decahydronaphthalene selectivity 100%, decalin The yield of naphthalene was 15%.

Embodiment 3

[0053] In the high-pressure stirred tank reactor (MS-50-316L type, 50mL), add Ru / NiCo / CNTs catalyst 0.1500g successively, tetralin is 10.0mL; Feed nitrogen (purity ≥ 99.999%) to remove the Air: feed hydrogen (purity ≥ 99.999%) to remove the nitrogen in the kettle, close the outlet valve, and then continuously feed hydrogen, when the reaction pressure is 4.5MPa. Start stirring at a stirring rate of 500r / min, and react at a constant temperature of 25°C for 13 hours. After the reaction stops, the remaining gas is discharged, and the product is obtained by centrifugation. The composition of the product is analyzed by gas chromatography. The reaction result is: selectivity of decalin 100%, decahydro The yield of naphthalene was 65%. In addition, the catalyst was reused 10 times without any decrease in its selectivity and activity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com