Mixed printing head type 3D printer

A 3D printer and print head technology, applied in 3D object support structures, additive manufacturing, coating devices, etc., can solve problems such as poor separation and mixing of liquid plastics, reduced connectivity of finished products, and reduced structural strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in detail below in conjunction with accompanying drawing:

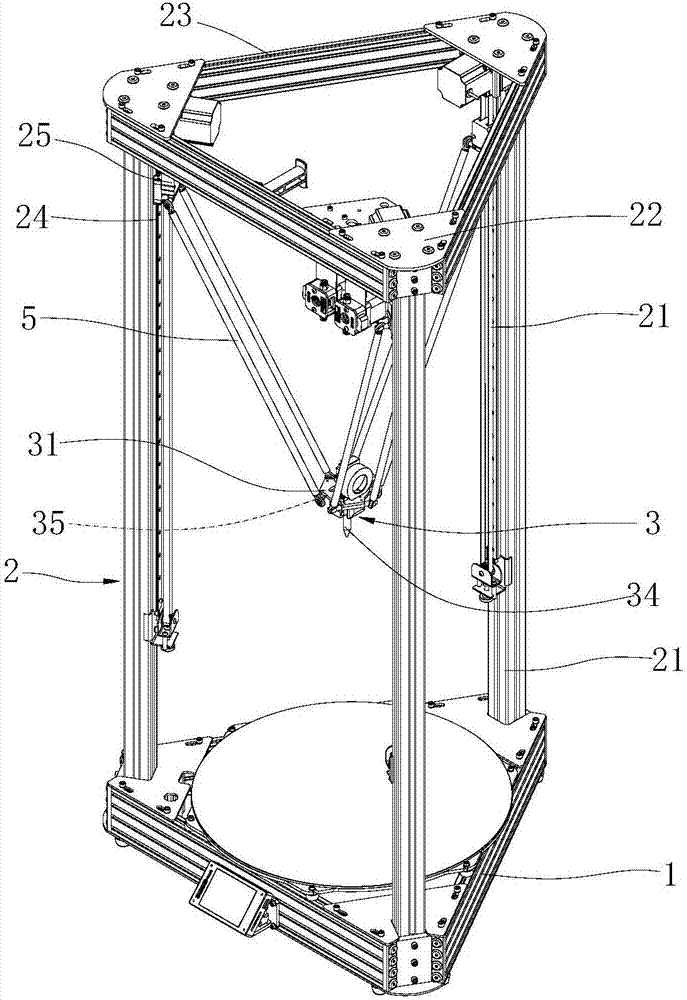

[0022] combine Figure 1 to Figure 5 , a mixed print head type 3D printer, including a base 1, a support 2, a print head mechanism 3 and a static mixer 4, the base 1 is connected to the support 2, and the support 2 is connected to the print head mechanism 3 through a connecting rod 5. The bracket 2 includes three columns 21 , three connecting heads 22 and three beams 23 , the three columns 21 are connected with the three connecting heads 22 , and the three beams 23 are connected between the three connecting heads 22 . A slideway 24 is arranged on the column 21 , and one end of the connecting rod 5 is connected with a slide block 25 on the slideway 24 .

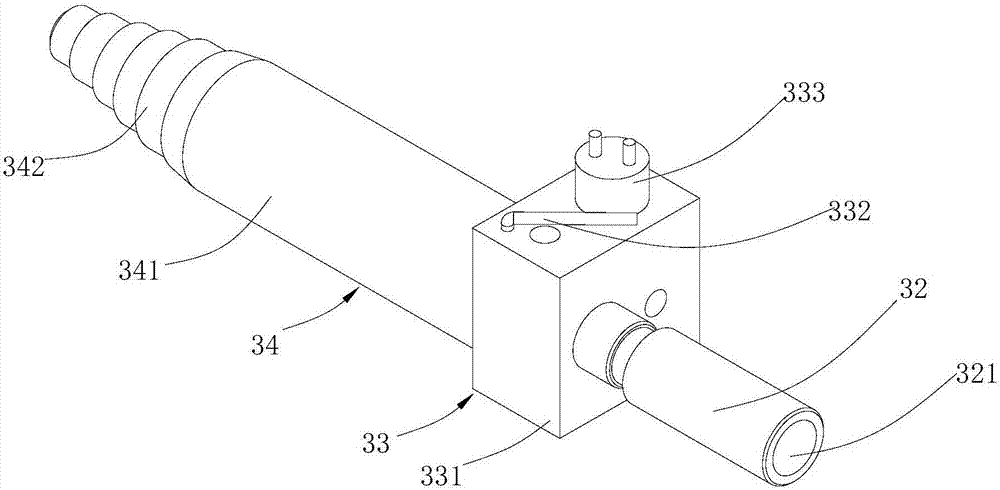

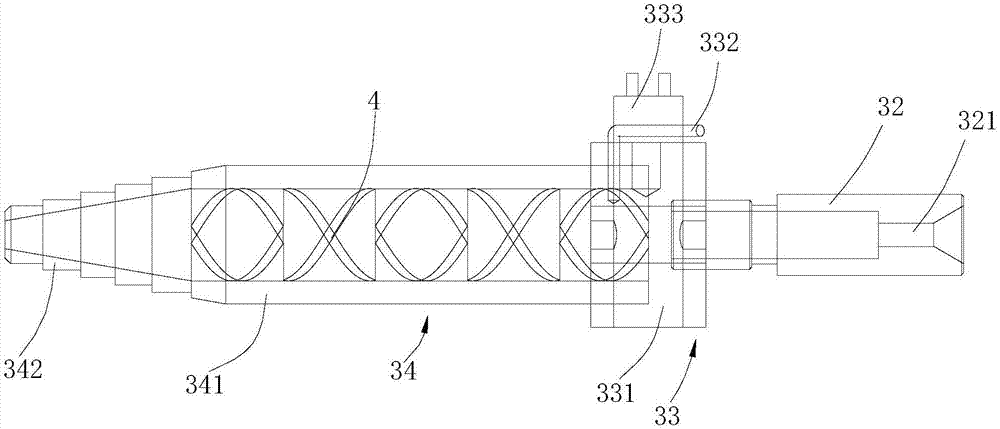

[0023] The print head mechanism 3 includes a positioning plate 31, a throat 32, a heating assembly 33 and a nozzle 34. The positioning plate 31 is provided with a positioning rod 35, and the connecting rod 5 is connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com